Printing unit of a carton printing machine

A printing unit, printing press technology, applied in printing presses, general parts of printing machinery, rotary printing presses, etc., can solve the problems of pigment spreading, short stroke, affecting printing effect, etc., to improve work efficiency and digest small errors , Improve the effect of continuous work accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific preferred structure of the printing unit of the carton printing machine applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

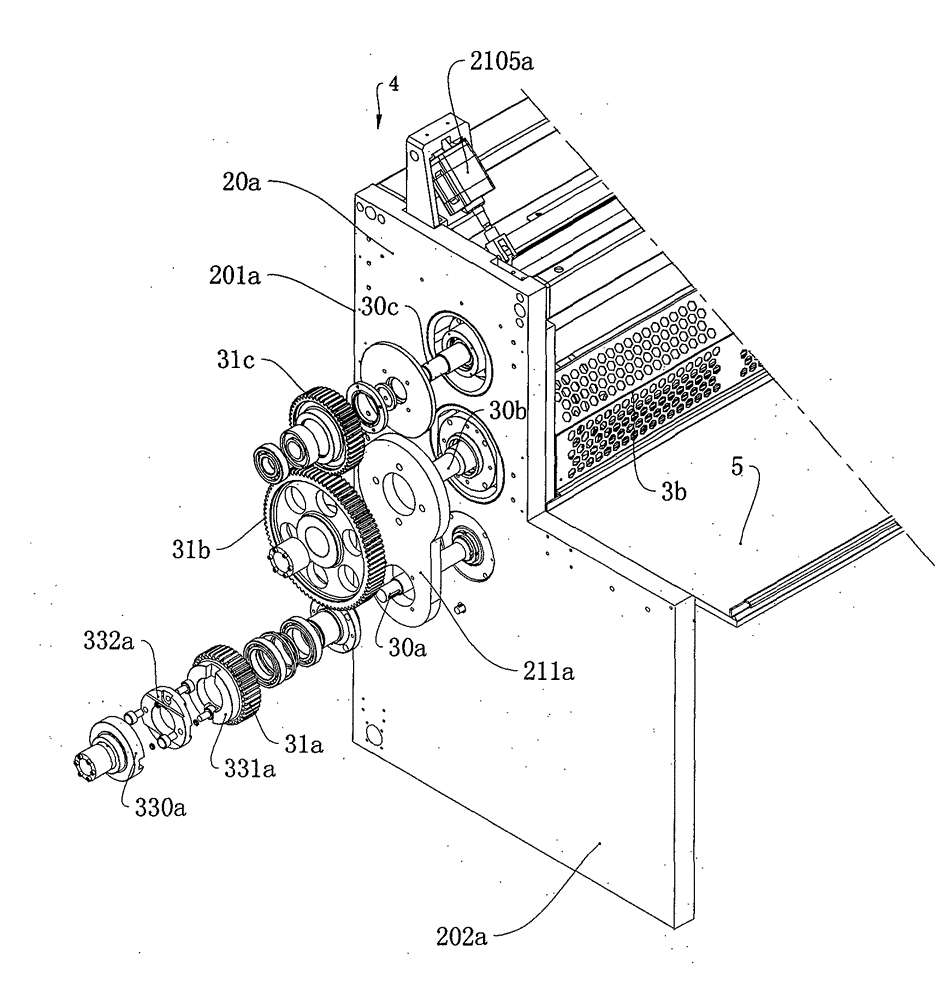

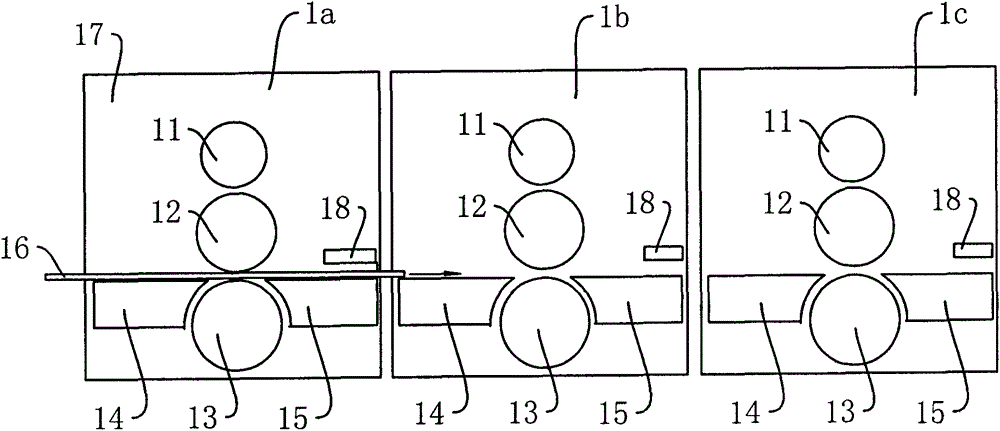

[0044] The carton printing machine includes a plurality of printing units 4 and feeding units (not shown in the figure) and the like. Such as image 3 As shown, it is a structural schematic diagram of one of the printing units 4 of the carton printing machine applying the technical solution of the present invention, and the printing unit 4 is a machine capable of printing patterns or characters on the surface of cardboard.

[0045] Described printing unit 4 comprises two sides frame (2a, 2b), and the embossing roller 3a that is rotatably arranged between two sides frame (2a, 2b), printing plate roll 3b and anilox roll 3c, described printing plate The roll 3b is located above the embossing roll 3a, and the anilox roll 3c is located above the printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com