Automatic cleaning device of spray nozzle

An automatic cleaning and nozzle technology, applied in the direction of spraying devices, etc., can solve the problems of affecting the effect of spraying paint or glue or gluing, blocking the outlet channel of the nozzle, not cleaning in time, etc., and achieves the effect of simple structure, reliable cleaning and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

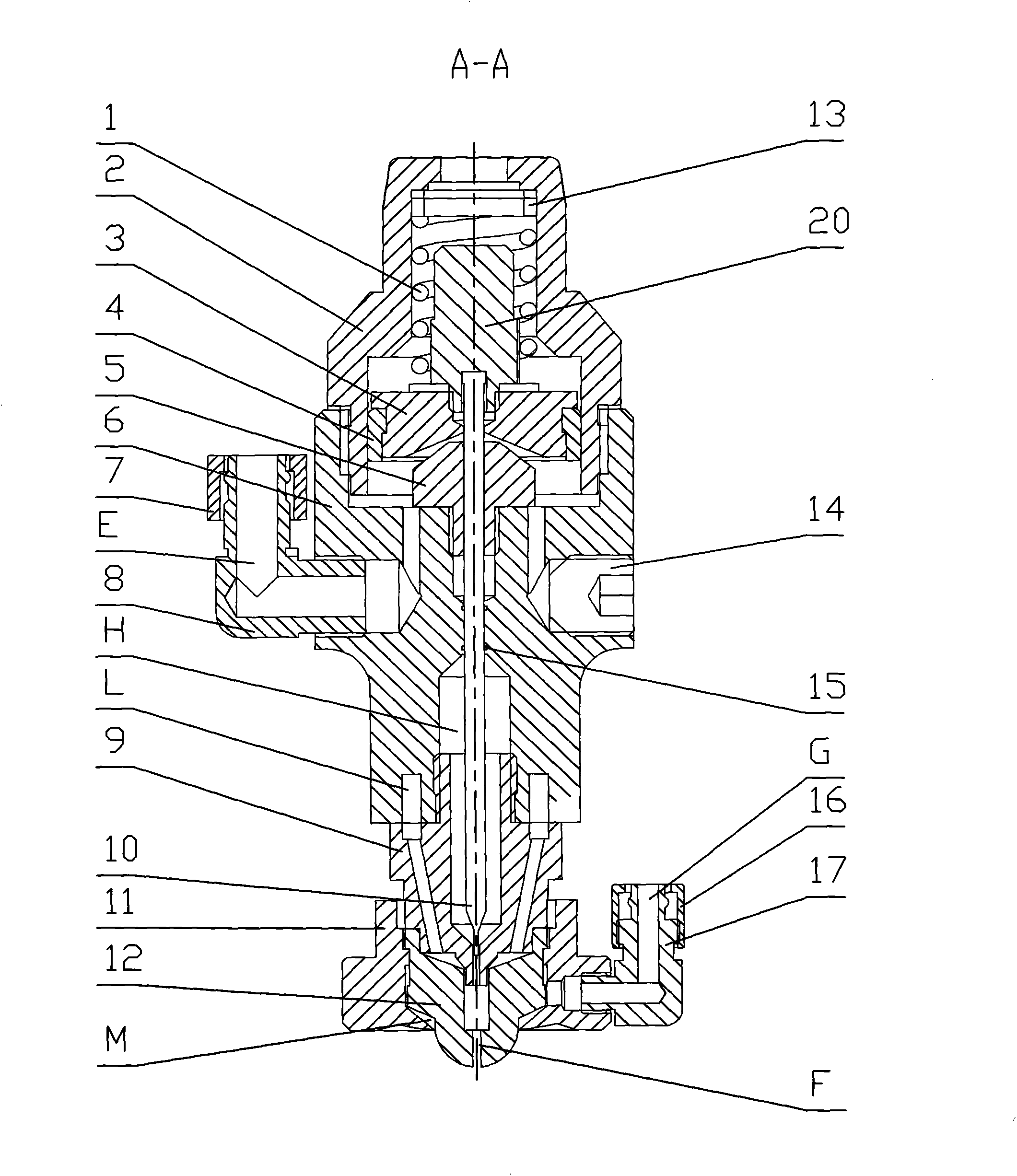

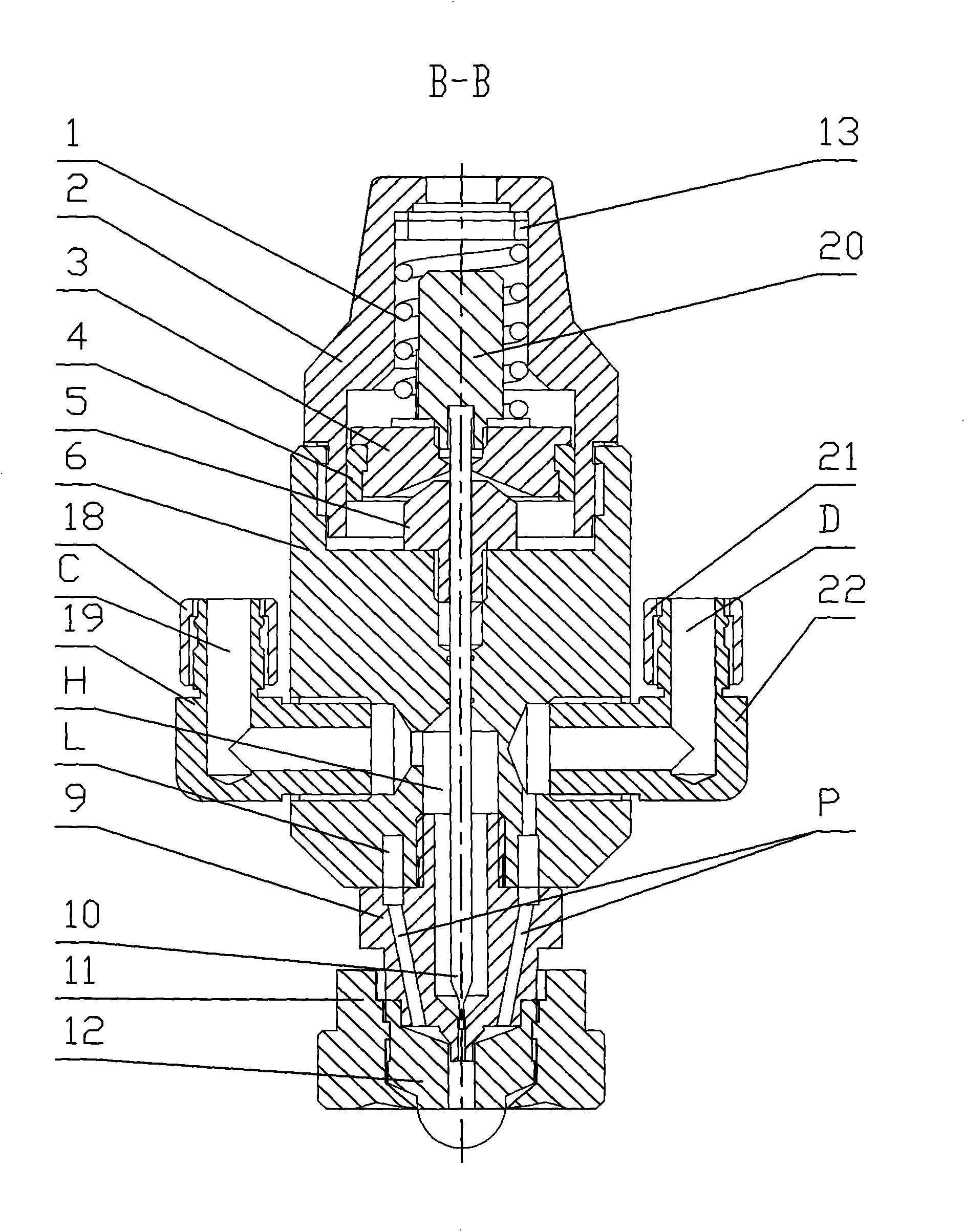

[0011] Specific implementation mode one: as Figure 1~3 As shown, in the nozzle automatic cleaning device described in this embodiment, a cleaning ring 11 and a solvent supply device are added outside the nozzle 12 of the spray gun. A solenoid valve is provided between the solvent supply device and the cleaning ring 11 and connected by a pipeline. The solenoid valve is used to close the solvent; the cleaning ring 11 is provided with a solvent inlet G, the lower end of the inner wall of the cleaning ring 11 is provided with an inner cone ring, the upper end of the inner wall of the cleaning ring 11 is provided with an internal thread, and the lower end of the nozzle 12 is provided with an outer cone. There is a boss on the upper end, and the cleaning ring 11 presses the boss of the nozzle 12 to fix it, and the nozzle 12 is fixed on the glue nozzle 9 by the cleaning ring 11; the outlet channel F communicates with the glue chamber H, and the outer circle of the glue nozzle 9 has ...

specific Embodiment approach 2

[0012] Specific implementation mode two: as Figure 1~3 As shown, in the nozzle automatic cleaning device described in this embodiment, the outer wall of the cleaning ring 11 is provided with a solvent inlet G, and the number of solvent inlets G can be 1-4, which are evenly distributed along the outer circle of the cleaning ring 11. The solvent nozzles 17 and The cleaning ring 11 is threaded. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: as Figure 1~3 As shown, in the nozzle automatic cleaning device described in this embodiment, the solenoid valve is arranged between the solvent supply device and the cleaning ring 11, the solenoid valve is connected to the valve, the valve is a needle valve and has a seal, and the solenoid valve controls the switch of the valve. Used to shut off the solvent. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com