Filtering device for high-viscosity fluids

A filter device and high viscosity technology, applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of flow rate reduction, change, and prolongation of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

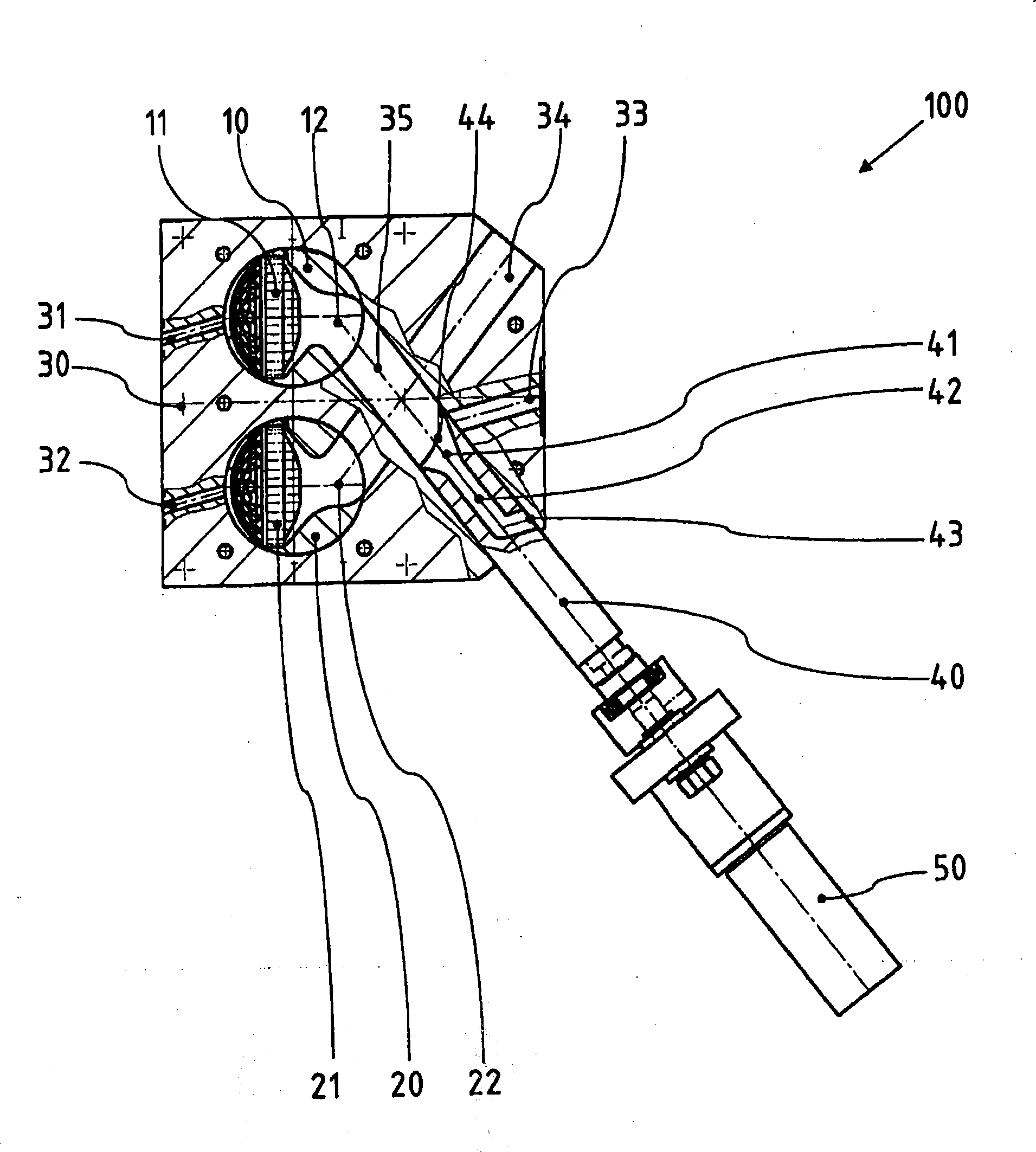

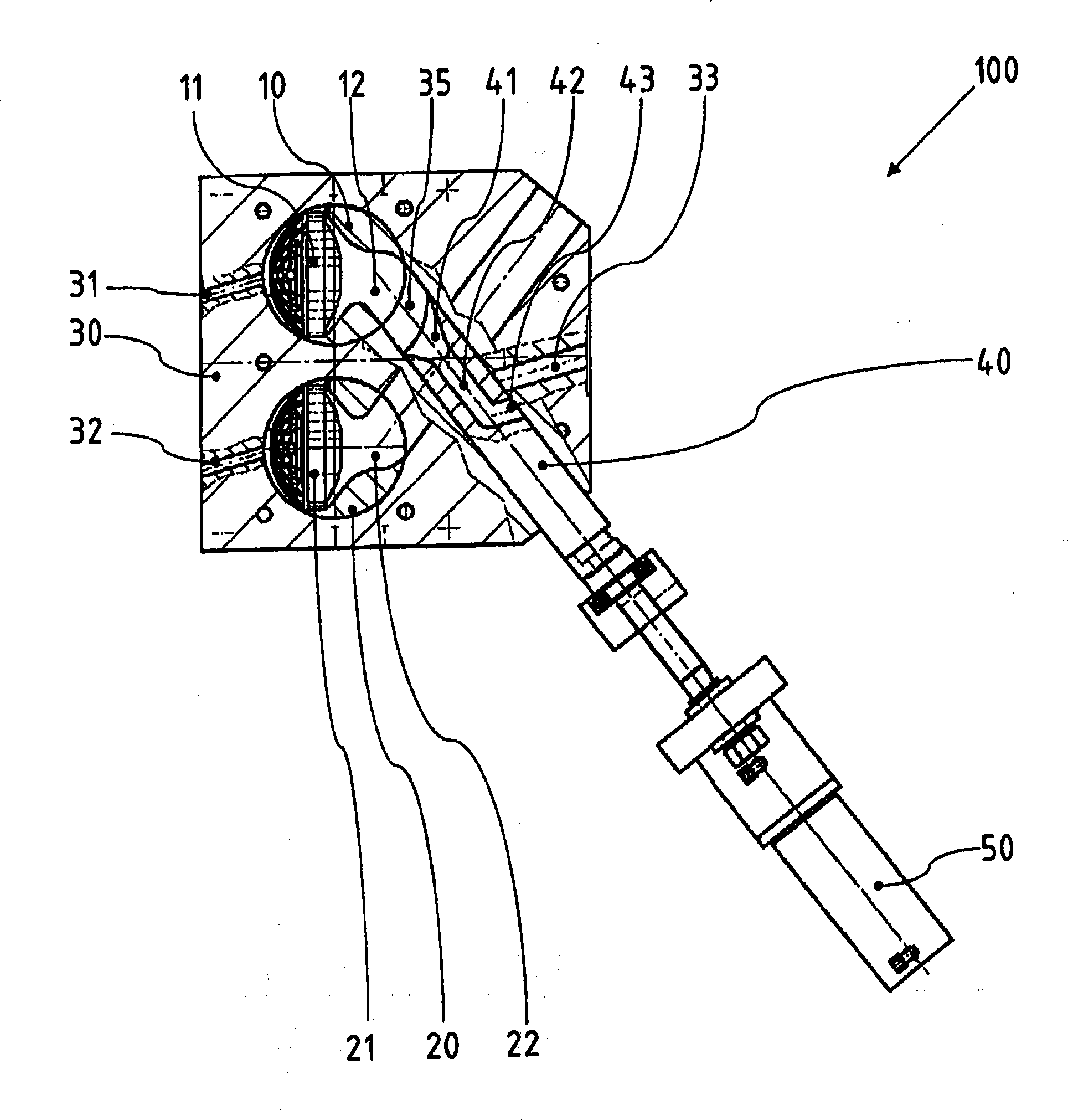

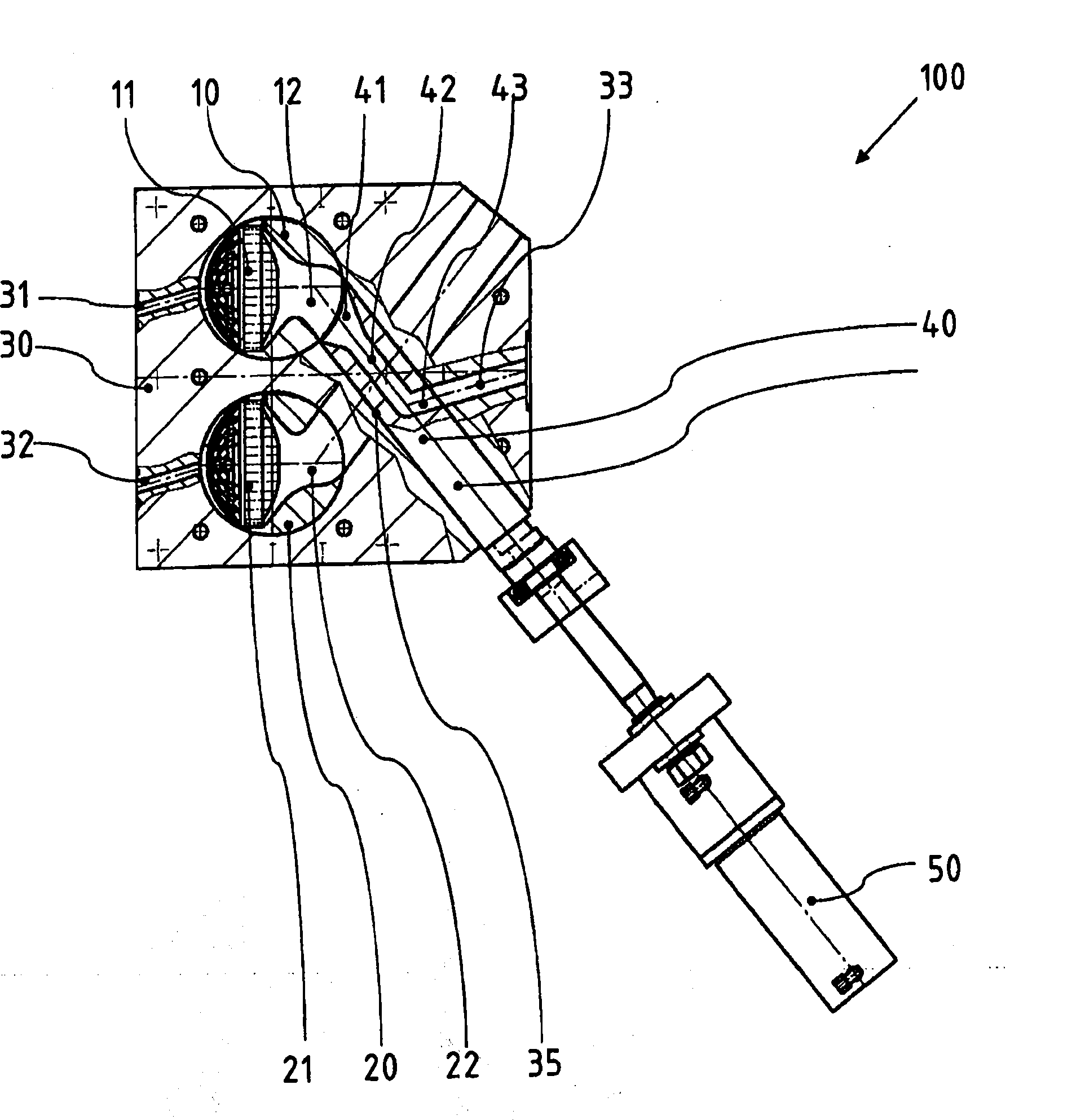

[0035] figure 1Shown is a filter device 100 formed as a screen plug body exchanger, consisting essentially of:

[0036] · Housing 30,

[0037] · Plunger-like screen carrying elements 10, 20, movably supported in housing bores

[0038] · one squeeze piston 40 per screen carrying element, and

[0039] • Drive 50 for extrusion piston 40 .

[0040] Each sieve carrying element 10,20 each has one figure 1 Screen space 12, 22 shown in section. One filter element 11 , 21 is inserted in each case in the screen space.

[0041] When the screen carrying elements 10, 20 are in the backwash position, on the dirt side, i.e. Figures 1 to 3 To the left in each case, the screen spaces 12 , 22 are each connected to a backflush channel 31 , 32 provided in the housing 30 .

[0042] figure 1 The sectional view is arranged so that the partial passages 34, 35 that are originally on the layered planes that are staggered from each other on the real object appear to be on a sectional plane. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com