Calibration device and method of six-axis force/torque sensor

A technology of torque sensor and calibration device, which is applied in the direction of calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc., which can solve problems such as machining errors, low accuracy, and large loading range, and achieve loading Stable force value, reduced workload, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

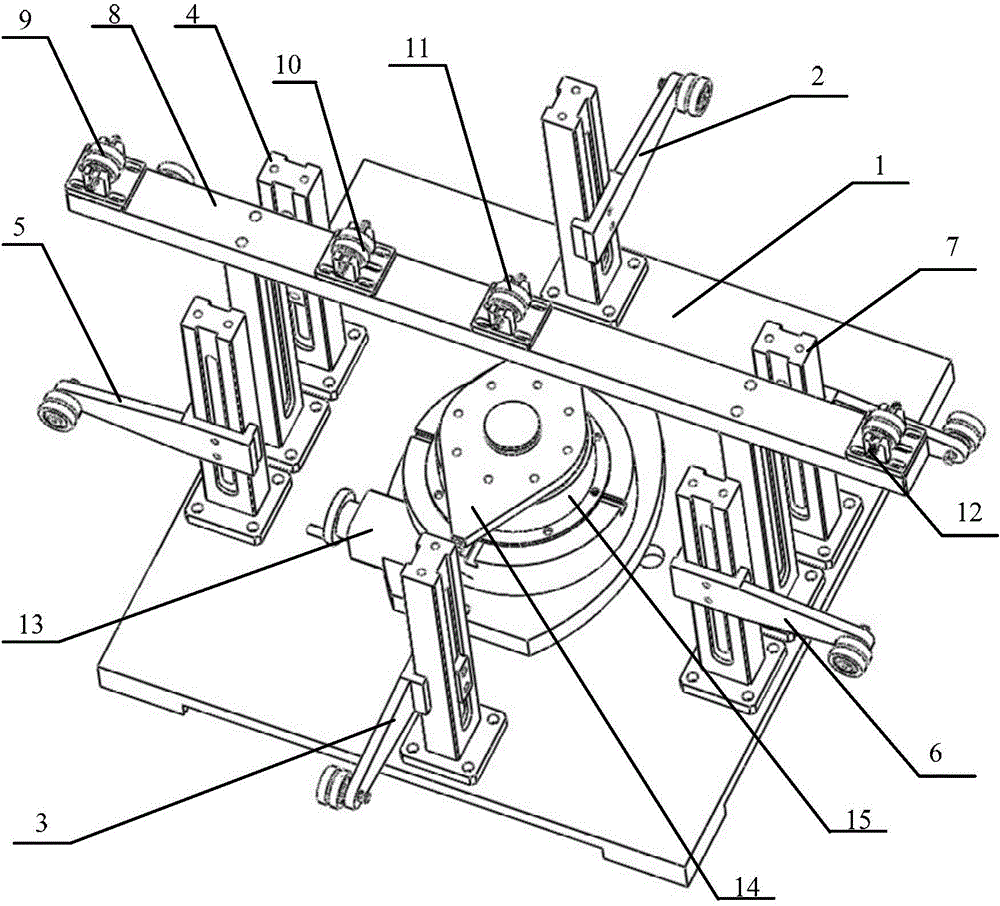

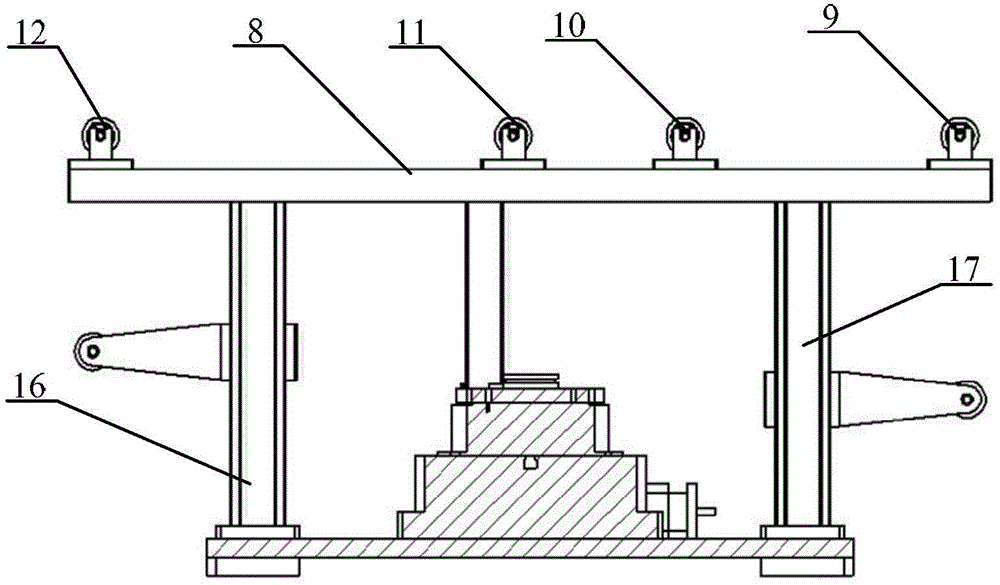

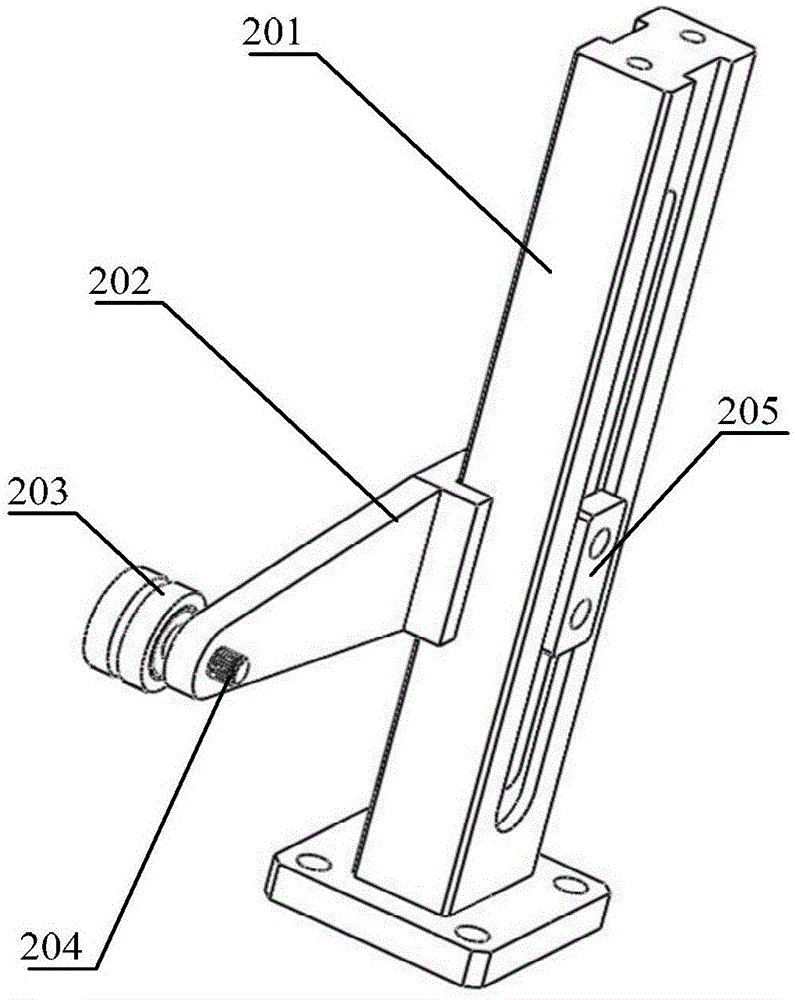

[0053] Such as figure 1 , figure 2 Shown is a six-dimensional force / torque sensor calibration device, which is characterized in that it includes a calibration table 1 , a rotary table 13 , a loading device, a calibration adapter device and a beam 8 .

[0054] Define the horizontal upper surface of the calibration workbench 1 as surface S, define the center point of surface S as point O, take point O as the intersection point, and define two vertically intersecting straight lines l on surface S 1 and l 2 .

[0055] The rotary table 13 is provided with a horizontal mounting surface, and the horizontal mounting surface is provided with a connection hole matching the bottom mounting hole 1503 of the six-dimensional force / torque sensor 15; the rotary table 13 is fixed on the calibration On the upper surface of the worktable 1, the center point of the bottom of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com