Grouting prefabricated pile and grouting method

A prefabricated pile and grouting technology, which is applied in sheet pile walls, buildings, and foundation structure engineering, can solve problems such as increasing the amount of steel and concrete used, low density of concrete pipe piles, and reducing the resistance to scuffing and bending. To achieve the effect of increasing the bearing area, increasing the bearing strength and expanding the friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

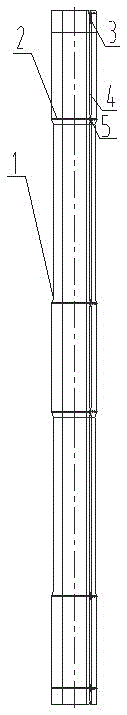

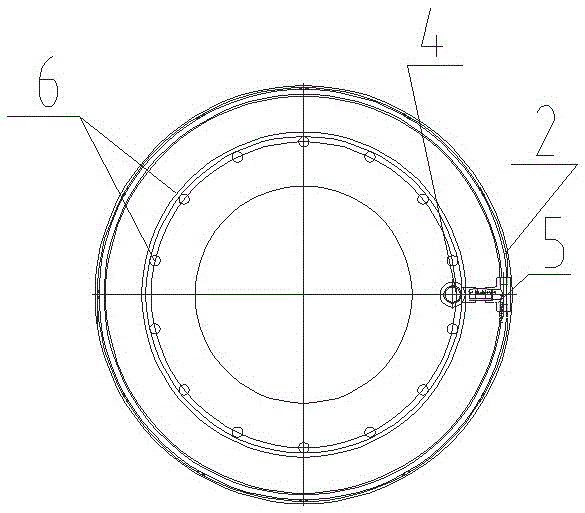

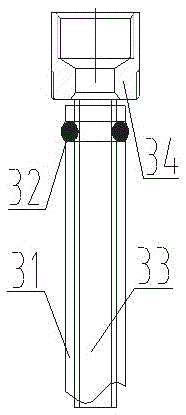

[0014] Embodiment 1: with reference to attached Figure 1-5 . A grouting prefabricated pile, comprising a prefabricated pile 1, a reinforcement cage 6 in the prefabricated pile 1 is vertically provided with more than one grouting pipe 4 erected, and a plurality of circumferential grouting pipes 2 are embedded in the prefabricated On the wall of the pile 1, a plurality of circumferential grouting pipes 2 communicate with the vertical grouting pipes 4 respectively, and a grouting hole 7 is circumferentially opened on the surface of the circumferential grouting pipes 2 . The plurality of circumferential grouting pipes 2 communicate with the vertical grouting pipes 4 through respective three-way valves 5 . The spray hole is in the shape of an outwardly expanded trumpet. The three-way valve 5 is a pressure spool three-way valve, or an electromagnetic three-way valve. The upper part of the vertical grouting pipe 4 is a telescopic structure 3 . The telescopic structure 3 is a coi...

Embodiment 2

[0015] Embodiment 2: on the basis of embodiment 1, a kind of manufacture method of grouting pipe pile, make reinforcement cage 6 according to conventional method, vertical grouting pipe 4 and reinforcement cage wall are fixed, a plurality of circumferential grouting pipes 2 Distributed in the form of bamboo joints from top to bottom on the periphery of the reinforcement cage 6, and a plurality of circumferential grouting pipes 2 are respectively connected to the vertical grouting pipes 4 through three-way valves 5, and then put into the pipe pile forming mold for centrifugal pile making .

Embodiment 3

[0016] Example 3: On the basis of Example 1, a grouting method for grouting pipe piles. When in use, put the grouting pipe piles into the piles buried in advance, and then put the high-pressure cement slurry through the vertical grouting At pipe 4, immediately after the high-pressure cement slurry is discharged from the lower end of the vertical grouting pipe, a part of the cement slurry is poured downward into the foundation, and a part of the cement slurry is turned up along the outer wall of the pipe pile. When the soil is mixed with a part of the cement slurry and the upward turning pressure reaches the set pressure value, the circumferential grouting pipe 2 on the prefabricated pile wall opens the valve core to the pile body sequentially according to the set pressure value from bottom to top. The surrounding space is subjected to high-pressure grouting step by step until the uppermost circumferential grouting pipe 2 of the prefabricated pile completes the high-pressure gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com