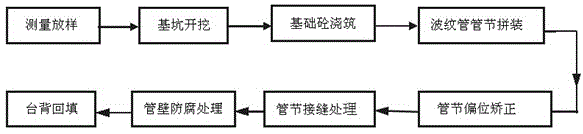

Steel corrugated pipe culvert construction method

A technology of corrugated pipe culverts and construction methods, which is applied in the direction of buildings and road floors, etc., can solve problems such as leakage, time-consuming construction, and easy dislocation of the foundation, and achieve the effects of uniform load distribution, rapid construction, and reduced operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0016] Measurement stakeout

[0017] Level the construction site, accurately stake out and measure the plane position and excavation depth of the culvert,

[0018] Excavation

[0019] The excavation of the foundation pit adopts mechanical excavation. If the groundwater is rich after the excavation of the foundation pit, a sump is dug outside the hole body of the excavation foundation pit, and the longitudinal excavation section along both sides of the foundation pit is 30×30cm The drainage ditch allows water to flow to the sump, and the water pump is set to pump and drain the groundwater in the foundation pit to the outside of the roadbed in time. After the excavation of the foundation pit is completed, the foundation bearing capacity test shall be carried out on the culvert base in time, and the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com