A New Transformer Turnover Box

A turnover box and transformer technology, applied in the direction of containers, rigid containers, packaging items, etc., can solve the problems of inconvenient storage management, difficulty in optimization, and inability to place them, and improve the degree of freedom in length and space, reduce rotation links, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

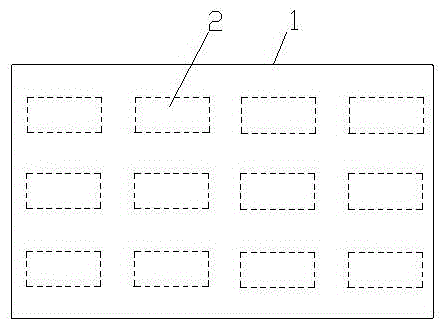

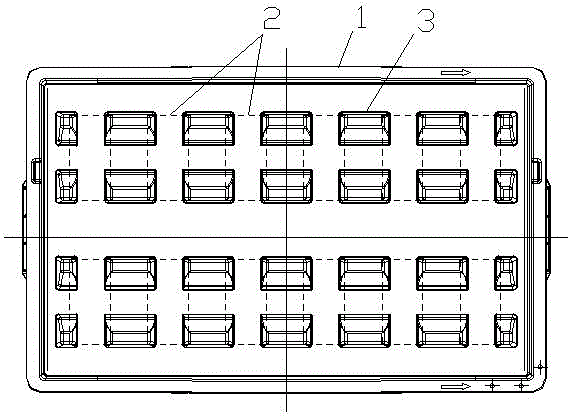

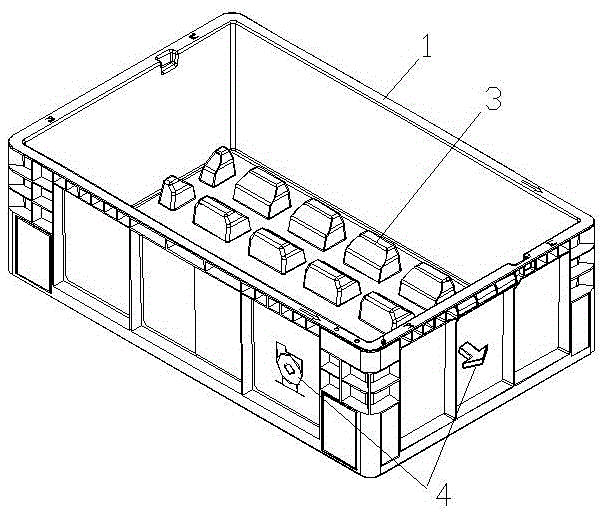

[0016] Such as figure 2 and image 3 As shown, the transformer turnover box of the present invention includes a rectangular box 1 with an upper opening, and the inner bottom of the box 1 is provided with several transformer positioning grooves 3 arranged in an array, and the positioning grooves 3 are arranged in a 2×6 array. And the positioning groove makes the length direction of the current transformer 2 be arranged along the width direction of the turnover box, that is, 6 rows of parallel current transformers are arranged in the length direction of the turnover box, and 2 current transformers are arranged in each row. The length direction of the current transformer runs along the width dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com