Corn skinning thresher

A thresher and corn technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of difficult threshing, wind dispersion, easy entanglement of corn leaves, etc., and achieve the effect of clean corn kernels and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

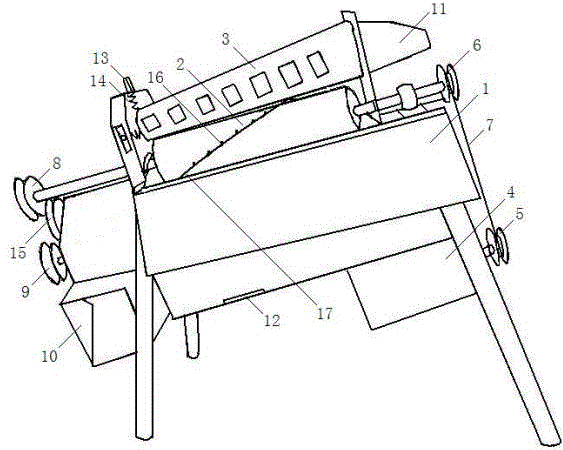

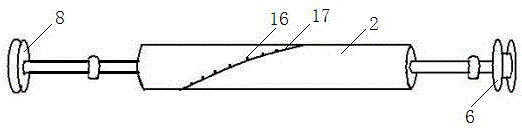

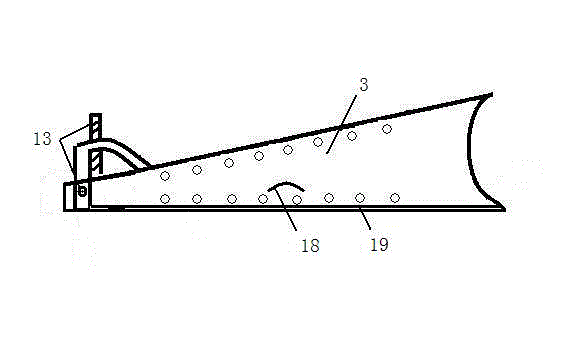

[0026] A corn peeling and threshing machine, comprising a frame 1, a drum 2, a threshing sieve plate 3, a motor 4, a pulley 5, a front pulley 6, a belt 7, a rear pulley 8, an exhaust fan pulley 9, an exhaust fan 10, and a feed port 11 , discharge port 12, automatic adjustment device 13, peeling protrusions 16, spiral ribs 17, fixed drum 2 above the frame 1, a threshing sieve plate 3 above the drum 2, spiral ribs 17 on the drum 2, and a threshing sieve plate 3 There is a feed inlet 11 at the front, an automatic adjustment device 13 at the end of the threshing sieve plate 3, a front pulley 6 at the front of the drum 2, a rear pulley 8 at the rear of the drum 2, and an exhaust fan 10 below the rear pulley 8. , exhaust fan 10 rear side is provided with exhaust fan pulley 9, is provided with motor 4 under frame 1 front, and is provided with pulley 5 at motor 4 front, and front pulley 6 is connected pulley 5 by belt 7, and is provided with under frame 1 rear. Discharge port 12 is ar...

Embodiment 2

[0028] The above-mentioned corn peeling and thresher, the peeling protrusion 16 is a cylinder with a length of 0.5cm ~ 1.5cm; a pinch pulley 15 is provided between the rear pulley 8 and the exhaust fan pulley 9, and the pinch pulley 15 is used to adjust The belt is elastic.

Embodiment 3

[0030] As the corn peeling and threshing machine described in the above-mentioned embodiment 2, the two drums 2 are arranged side by side to form a double-barrel peeling and threshing machine, and a threshing sieve plate 3 is arranged above the drum 2 to increase the amount of peeling and threshing; The direction of rotation is set in S shape, and a screen is set under the drum 2. The diameter ratio of the pulley 5 and the front pulley 6 is 1:1, the ratio of the diameter of the front pulley 6 and the rear pulley 8 is 1:1, and the rear pulley 8 and the exhaust fan Pulley 9 wheel diameter ratio is 1:0.8~1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com