Magnetic force drive robot for overhead high-tension transmission line operation

A high-voltage transmission line, magnetic drive technology, applied in overhead lines/cable equipment, holding devices with magnetic attraction or thrust, electrical components, etc., can solve the problems of high cost, large weight and size, and low cruising speed of drive modules , to achieve the effect of eliminating slippage, increasing moving speed and simplifying the drive mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

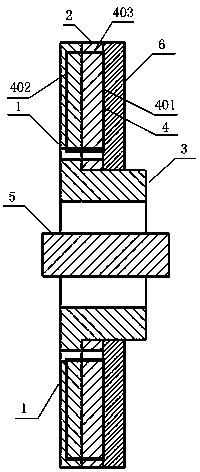

[0041] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

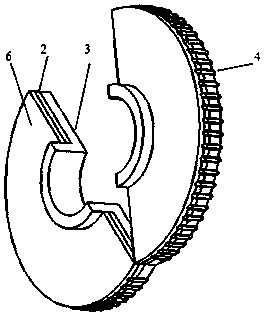

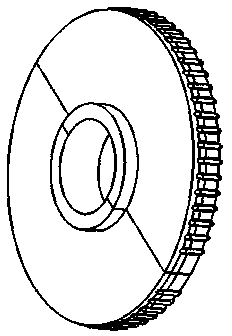

[0042] see figure 1 , figure 2 , image 3 and Figure 4 , a magnetic drive method for a robot working on overhead high-voltage transmission lines, using the magnetic field generated by high-voltage current to drive the robot to move by the ampere force of the current-carrying wire; it includes two driving tiles 1 with the same structure, which can be opened and closed, and where the high-voltage wire 5 can pass through. , the driving tile 1 is composed of a magnetic core 2 , a magnetic core cover 6 , a lining tile 3 and a rectangular coil 4 .

[0043] see Figure 5 and Figure 12 , the magnetic core cover 6 is made of a strong magnetic material, and is in a thin semi-cylindrical shape with a radius of 100mm. With the axis of the semi-cylindrical shape as the center, there is a magnetic core cover tile groove 601 with a radius o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com