A spring shock-absorbing type phase-to-phase anti-galling spacer

An interphase spacer and anti-galling technology, which is applied in the direction of mechanical vibration attenuation devices, devices for maintaining the distance between parallel conductors, etc., can solve the lack of ways to release line galloping energy, affect the safe and stable operation of transmission lines, and cannot quickly eliminate line galloping, etc. problem, to achieve the effect of suppressing sub-gap vibration, simple and practical structure, and suppressing breeze vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

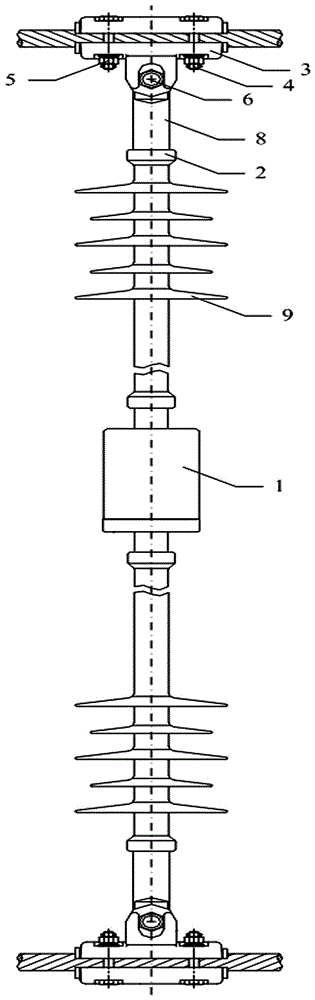

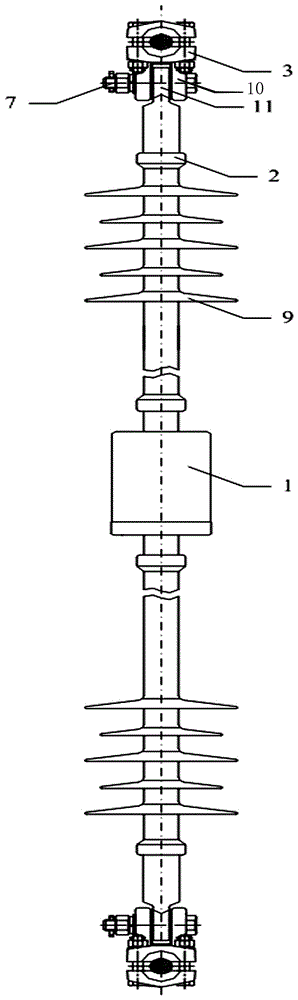

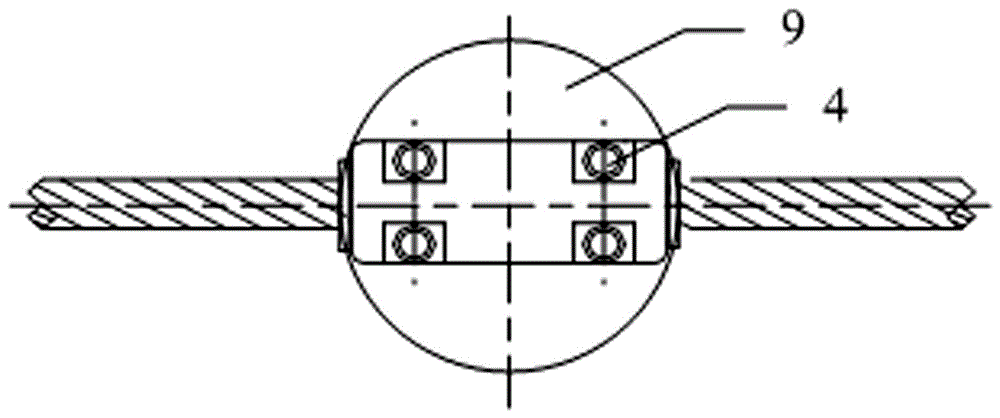

[0020] The present invention is a spring shock-absorbing type interphase anti-galling spacer, such as Figure 1 ~ Figure 4 As shown, the present invention includes a sleeve type anti-galling shock absorber 1, two interphase spacer rod insulators 2, two sets of wire clamp glands 3, two sets of wire clamp fastening bolt pins 4 and wire clamp fastening bolt nuts 5 , Two groups of spacer bar fastening bolt pins 6 and spacer bar fastening bolt nuts 7 are formed. Specifically, the anti-galling shock absorber 1 is connected to the middle of the two interphase spacer insulators 2 through connecting fittings 8;

[0021] The wire clip gland 3 is respectively provided with a wire clip gland double-ear structure 10 or a single-ear structure 11 for connecting fittings.

[0022] The anti-galling shock absorber 1 of the present invention is to be provided with the guide bar 13 that has convex buckle baffle plate 14 in the shock absorber sleeve shell 16, and the shock absorber damping spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com