Motor driven semitrailer supporting device

A support device and motor-driven technology, applied in vehicle maintenance, transportation and packaging, lifting vehicle accessories, etc., can solve the problems of not fully utilizing the effective length of the screw, low work efficiency, small expansion space, etc., to achieve simple structure, The effect of reducing labor intensity and large expansion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

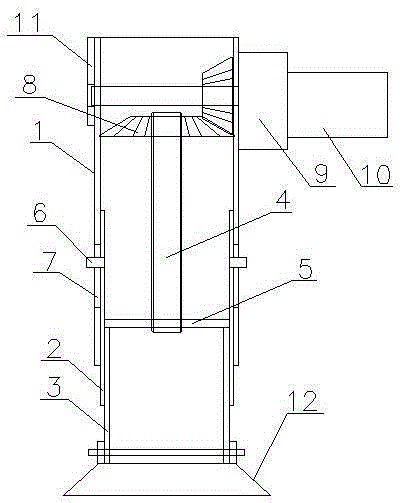

[0013] A support device for a motor-driven semi-trailer, comprising an outer support leg, a middle support leg 2 and an inner support leg 3, the outer support leg 1, the middle support leg 2 and the inner support leg 3 are sequentially connected in a sliding manner, and the outer support leg 1 is provided with a screw rod 4, the lower end of the screw rod 4 is covered with a nut 5, the nut 5 is fixedly connected with the upper end of the inner support leg 3, the middle support leg 2 is provided with a limit pin 6, and the side wall of the outer support leg 1 A limit groove 7 is correspondingly provided on the top, and the limit pin 6 is stuck in the limit groove 7 and can move up and down. The upper end of the screw rod 4 is connected with the gear transmission mechanism 8, and the input shaft of the gear transmission mechanism 8 is connected with a reduction gear. mechanism 9, the input shaft of the reduction gear mechanism 9 is connected with a drive motor 10; the drive motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com