Two-degree-of-freedom high-precision large-stroke air-bearing workpiece platform

A high-precision, high-degree-of-freedom technology, applied in the direction of photolithography exposure devices, microlithography exposure equipment, etc., can solve the problems of limited rigidity, large height, unfavorable engineering realization, etc., and achieve lower processing accuracy requirements and high air flotation stiffness , to ensure the effect of the air film unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the specific implementation of the present invention will be described in detail below.

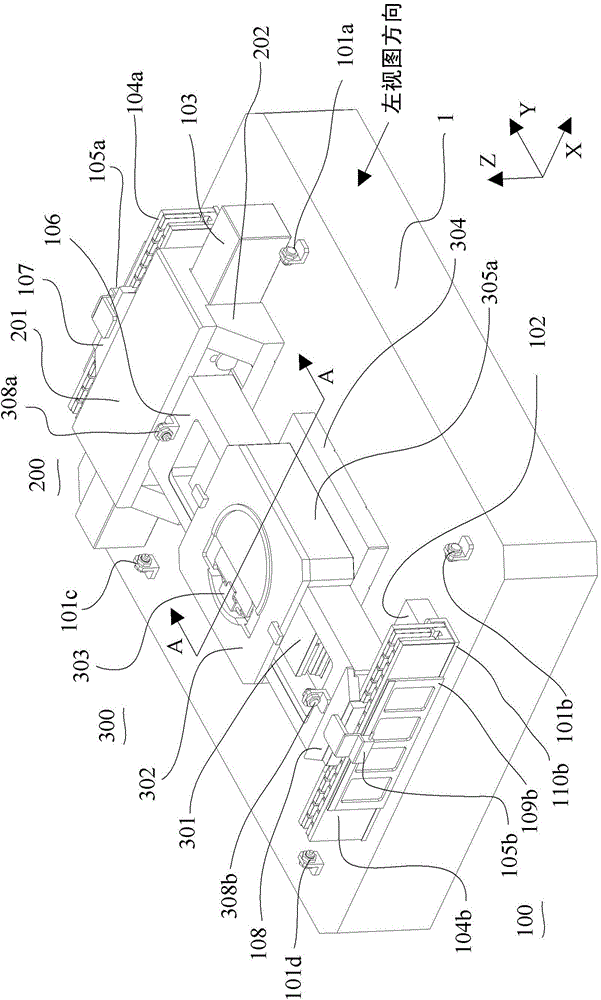

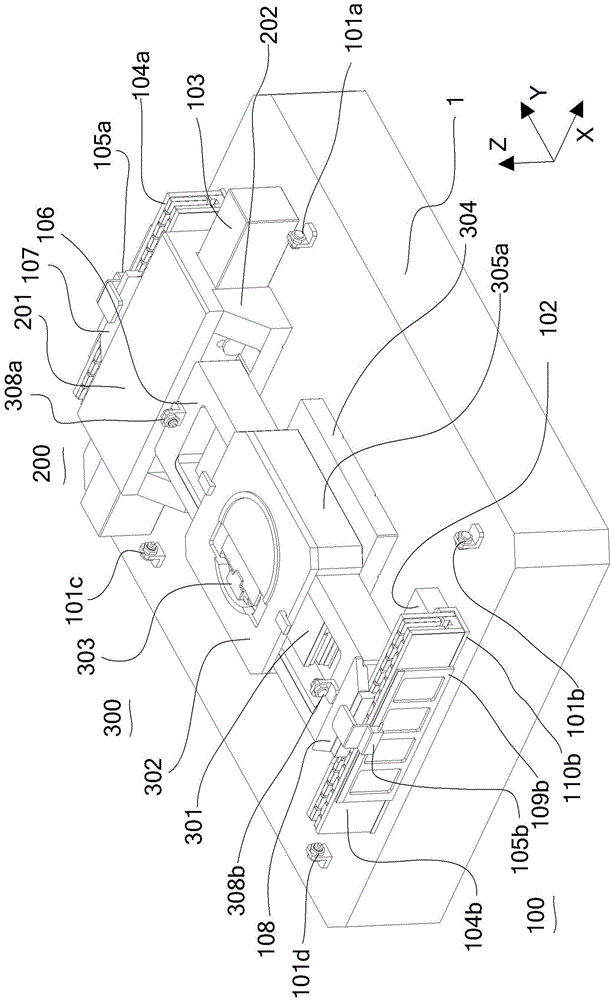

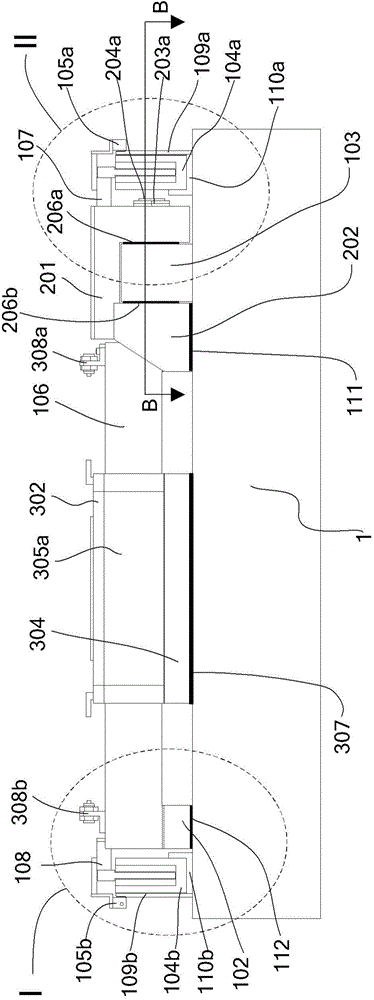

[0043] Such as Figure 1a , Figure 1b As shown, the two-degree-of-freedom high-precision large-stroke air-floating workpiece table of the present invention is composed of a marble base 1 , an X-direction motion table 100 and a Y-direction motion table 300 . The marble base 1 is located at the bottom of the X-direction motion table 100 and the Y-direction motion table 300, and is used to support the entire X-direction motion table 100 and the Y-direction motion table 300; the Y-direction motion table 300 is erected on the X-direction motion table 100, and the Y direction The motion table 300 and the X-direction motion table 100 are coupled through the X beam 106 to complete the transmission of the X-direction motion to the Y-direction motion table, so that the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com