Gas turbine fuel oil metering method based on electric pump

A technology for gas turbines and metering methods, which is applied in the direction of volume/mass flow generated by mechanical effects, fixed measuring chambers, and fluid flow detection by measuring differential pressure, which can solve the problems of reliability, cost, and metering accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

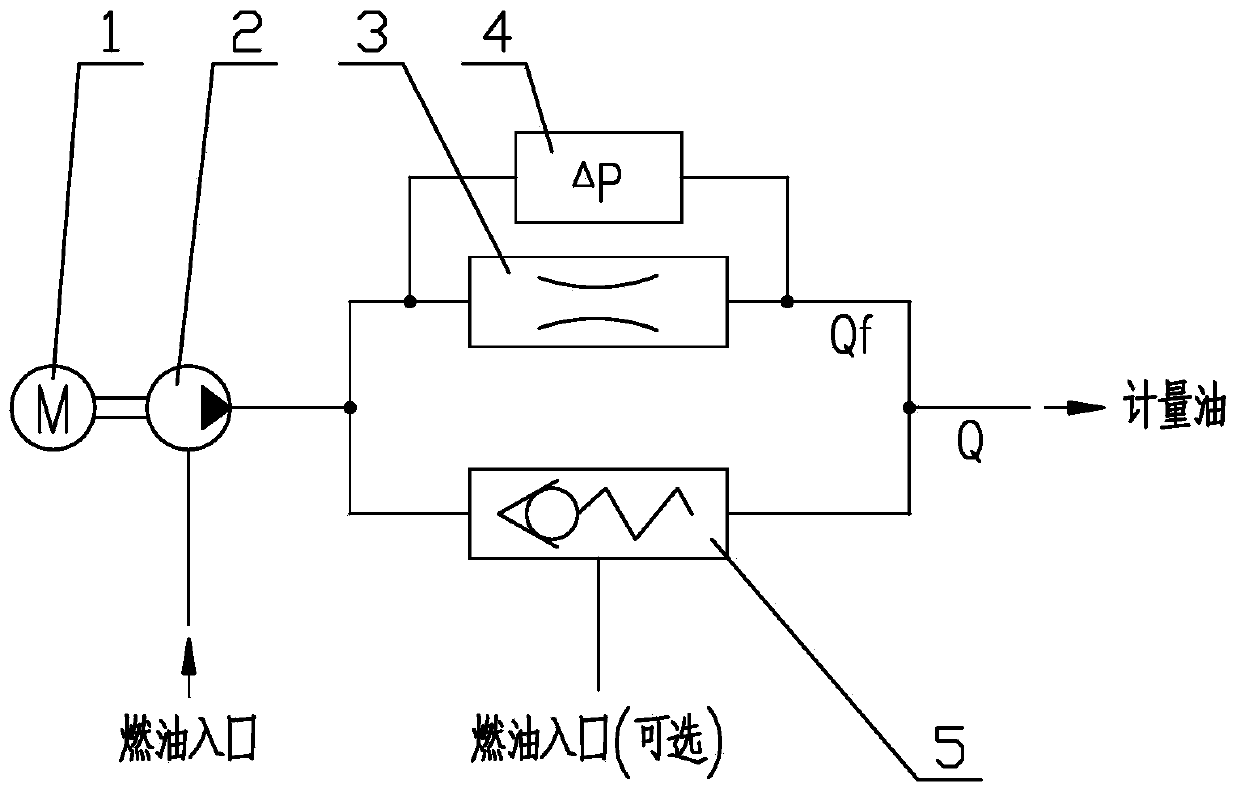

[0036] This embodiment provides a gas turbine fuel metering method based on an electric pump, characterized in that: the electric pump-based gas turbine fuel metering method includes the following steps;

[0037] 1) The displacement fuel pump is driven by a speed-regulating motor to change the fuel flow;

[0038] 2) Parallel throttling device and pressure limiting device at the outlet of positive displacement pump;

[0039] 3) Use a differential pressure measuring device to measure the pressure difference between the inlet and outlet of the throttling device;

[0040] 4) Properly set the opening pressure of the pressure limiting device so that the device is closed during the start-up of the gas turbine and opened after start-up;

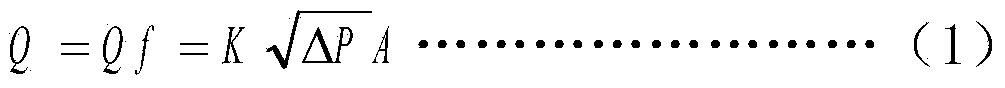

[0041] 5) During the starting process, the pressure limiting device is closed, and the fuel flow is accurately calculated using the flow area of the throttling device and the pressure difference between the inlet and outlet;

[0042] 6) After sta...

Embodiment 2

[0053] This embodiment provides a gas turbine fuel metering method based on an electric pump, characterized in that: the electric pump-based gas turbine fuel metering method includes the following steps;

[0054] 1) The displacement fuel pump is driven by a speed regulating motor to change the fuel flow;

[0055] 2) Parallel throttling device and pressure limiting device at the outlet of positive displacement pump;

[0056] 3) Use a differential pressure measuring device to measure the pressure difference between the inlet and outlet of the throttling device;

[0057] 4) Properly set the opening pressure of the pressure limiting device so that the device is closed during the start-up of the gas turbine and opened after start-up;

[0058] 5) During the starting process, the pressure limiting device is closed, and the fuel flow is accurately calculated by using the flow area of the throttling device and the pressure difference between the inlet and outlet;

[0059] 6) After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com