System and method for measuring line sag height based on unmanned aerial vehicle

A measurement line and measurement system technology, applied in the field of aerial measurement, can solve the problems of poor measurement accuracy, use restrictions, measurement difficulties, etc., and achieve the effects of labor-saving measurement efficiency and strong site adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

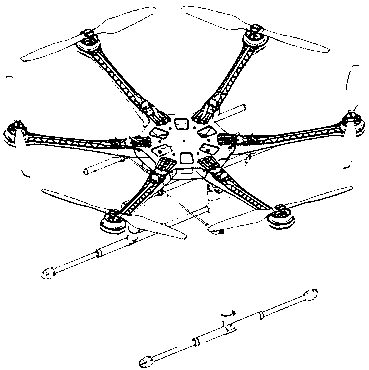

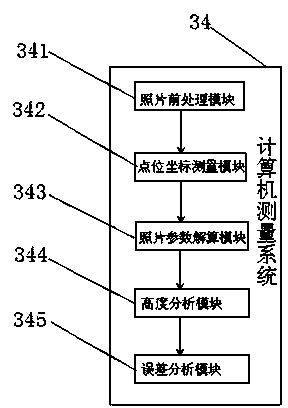

[0024] as attached figure 1 , attached figure 2 , attached image 3 As shown, the present embodiment is based on a system for measuring the sag height of a line by an unmanned aerial vehicle, including a rotor unmanned aerial vehicle 1 with a GPS positioning device, a digital camera 2, a microwave transmitter 41, a ground control station 3, a microwave receiving antenna 42, Data line 5 and computer measurement system 34, digital camera 2 and microwave launcher 41 are installed on the described rotor drone 1, and described digital camera 2 and microwave launcher 41 are connected by the flight control panel 11 of drone, computer The measurement system 34 is installed on the ground control station 3 , and the computer serial port 31 on the ground control station 3 is connected to the microwave receiving antenna 42 through the data line 5 . The flight control board 11 is an electronic integrated chip, which can realize functions such as automatic flight of the drone and data c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com