A defrosting system of an air-cooled refrigerator and a defrosting control method thereof

An air-cooled refrigerator and control method technology, applied in defrosting, household refrigeration equipment, household appliances, etc., can solve the problems of low defrosting efficiency, large defrosting residual heat, unevenness, etc., and achieve long defrosting time, defrosting The effect of low energy consumption and small temperature fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

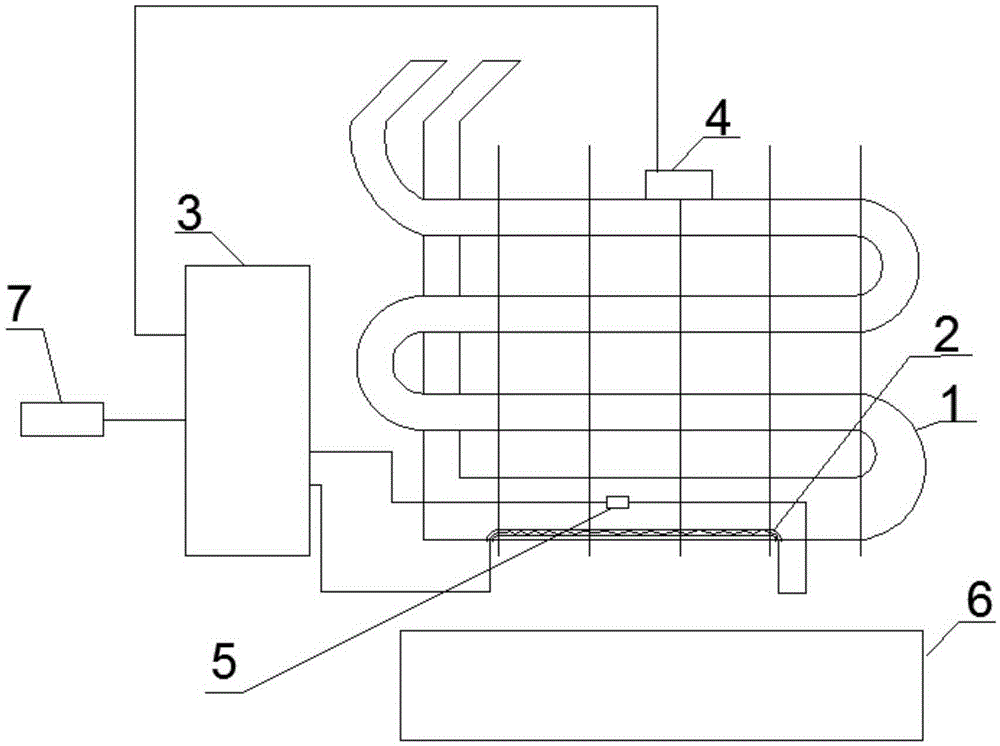

Method used

Image

Examples

Embodiment 1

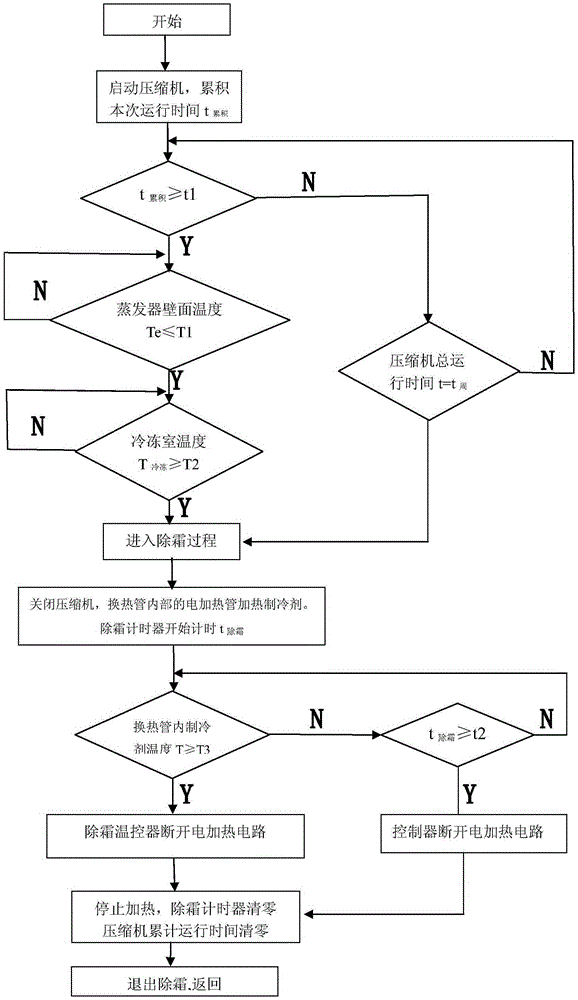

[0028] Such as image 3 As shown, the control method of the defrosting system of the air-cooled refrigerator in this embodiment includes the following steps:

[0029] Step 1: When the air-cooled refrigerator is in cooling operation, the compressor starts, and the controller 3 starts to accumulate the running time of the compressor. When the controller 3 detects that the accumulated running time of the compressor is t 累积 ≥t 1 , t 1 =60min, evaporator heat exchange tube wall temperature Te≤T 1 ,T 1 =-30℃, and freezer temperature T 冷冻 ≥T 2 when T 2 =-20°C; or when the total running time of the compressor reaches the set defrosting cycle t 周期 , enter the defrosting process;

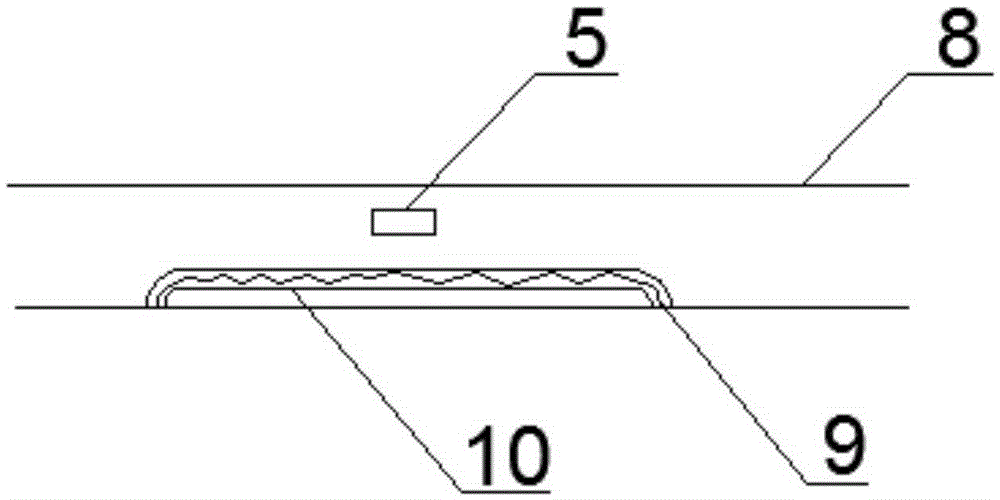

[0030] Step 2: During defrosting, the controller 3 turns off the compressor, turns on the defrosting electric heating circuit to heat the electric heating wire 9, and at the same time the controller 3 starts timing the defrosting time; the electric heating tube 2 transfers heat to the evaporator 1 Th...

Embodiment 2

[0034] Such as image 3 As shown, the control method of the defrosting system of the air-cooled refrigerator in this embodiment includes the following steps:

[0035] Step 1: When the air-cooled refrigerator is in cooling operation, the compressor starts, and the controller 3 starts to accumulate the running time of the compressor. When the controller 3 detects that the accumulated running time of the compressor is t 累积 ≥t 1 , t 1 =600min, evaporator heat exchange tube wall temperature Te≤T 1 ,T 1 =-5℃, and freezer temperature T 冷冻 ≥T 2 when T 2 =-5°C; or when the total running time of the compressor reaches the set defrosting cycle t 周期, enter the defrosting process;

[0036] Step 2: During defrosting, the controller 3 turns off the compressor, turns on the defrosting electric heating circuit to heat the electric heating wire 9, and at the same time the controller 3 starts timing the defrosting time; the electric heating tube 2 transfers heat to the evaporator 1 The ...

Embodiment 3

[0040] Such as image 3 As shown, the control method of the defrosting system of the air-cooled refrigerator in this embodiment includes the following steps:

[0041] Step 1: When the air-cooled refrigerator is in cooling operation, the compressor starts, and the controller 3 starts to accumulate the running time of the compressor. When the controller 3 detects that the accumulated running time of the compressor is t 累积 ≥t 1 , t 1 =100min, evaporator heat exchange tube wall temperature Te≤T 1 ,T 1 =-20℃, and freezer temperature T 冷冻 ≥T 2 when T 2 =-15°C; or when the total running time of the compressor reaches the set defrosting cycle t 周期 , enter the defrosting process;

[0042] Step 2: During defrosting, the controller 3 turns off the compressor, turns on the defrosting electric heating circuit to heat the electric heating wire 9, and at the same time the controller 3 starts timing the defrosting time; the electric heating tube 2 transfers heat to the evaporator 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com