A method for harmless and efficient fire treatment of waste circuit boards

A waste circuit board, fire treatment technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of air pollution, large amount of waste residue treatment, poor separation effect, etc., to avoid harm to workers, recycle High material value and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Precondition: The equipment of the present invention must be installed next to the hazardous waste incineration disposal equipment in the hazardous waste disposal site.

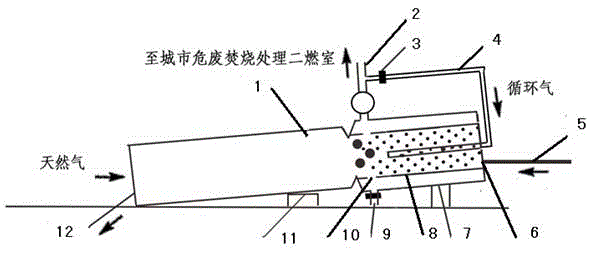

[0022] Implement this method, must adopt the detinning incineration integrated rotary kiln structure of following structure, see figure 1 :

[0023] The integrated rotary kiln for detinning and incineration is divided into two parts, the front section is the detinning chamber, and the rear section is the incineration chamber 1, which is arranged obliquely. sports.

[0024] The front detinning chamber is equipped with a feed inlet 6 at the high end, which is connected to the chain plate automatic continuous feeding device 5, and the chain plate is used to feed continuously from the top of the rotary kiln. The entire combustion chamber is under negative pressure, and the feed inlet should be closed accordingly. device.

[0025] The bottom of the incineration chamber 1 in the rear stage is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com