Tread stair and tread plates thereof

A technology for treads and stairs, applied in the field of stairs, can solve the problems of material waste, long processing time, and damaged surfaces, and achieve the effects of firm structural connection, good waterproof function, and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

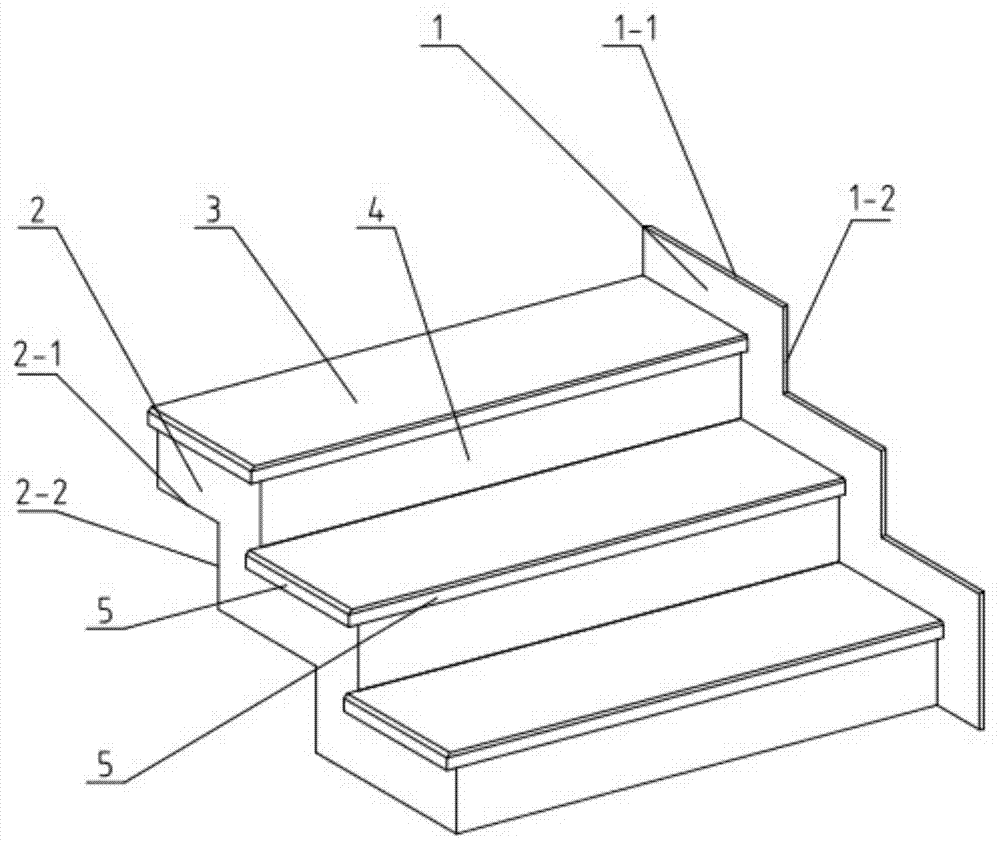

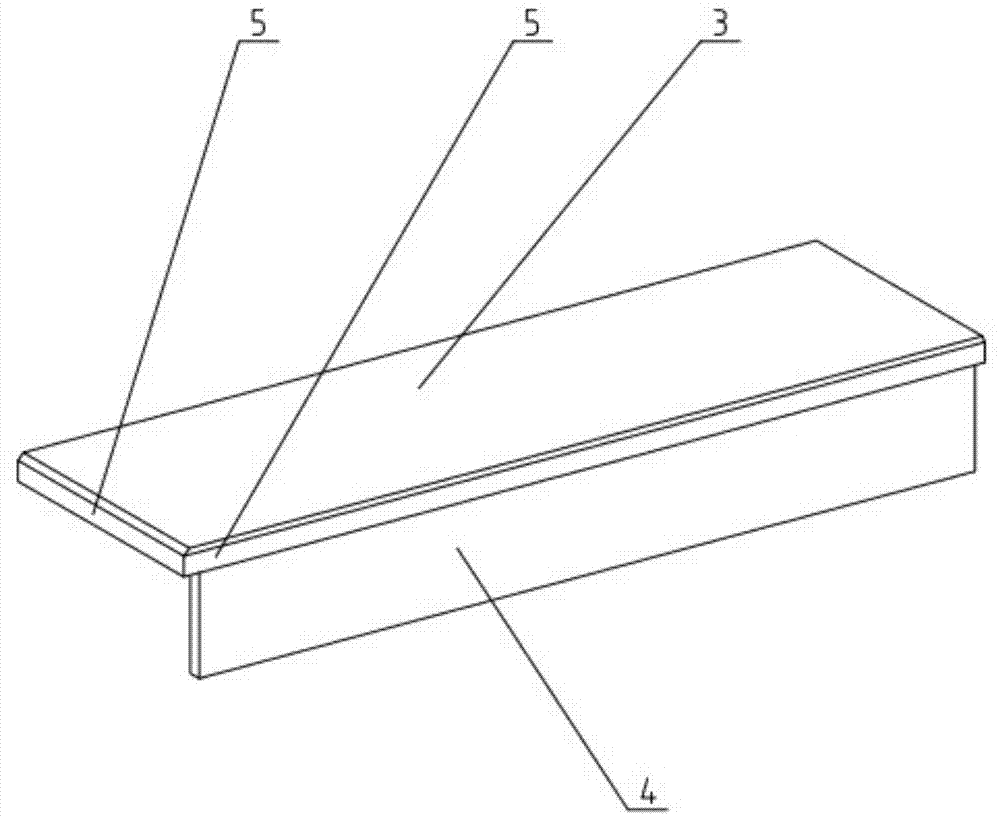

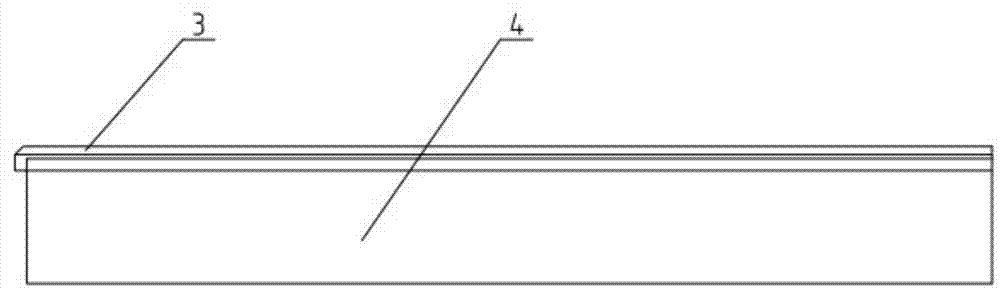

[0021] Such as Figure 1~4 Shown, a kind of stepping staircase, it comprises upper water retaining plate 1, lower water retaining plate 2 and multi-stage tread plate, tread plate comprises step main plate 3 and step side plate 4, one end of step main plate 3 in each step plate Splicing connection with one end of the step side plate 4 without bonding, the other end of the step side plate 4 is spliced with the step main board 3 in the adjacent step plate, the upper water retaining plate 1 and the lower water retaining plate 2 are respectively located on both sides of the multi-stage step board. The connection between the upper water retaining plate 1 and the lower water retaining plate 2 is not bonded, but directly connected by splicing, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com