Assembled adjustable high voltage reactor foundation

A high-voltage, prefabricated technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of complex construction process, affecting the construction period, and inability to deploy, so as to reduce air pollution and noise pollution, facilitate on-site installation, shorten The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

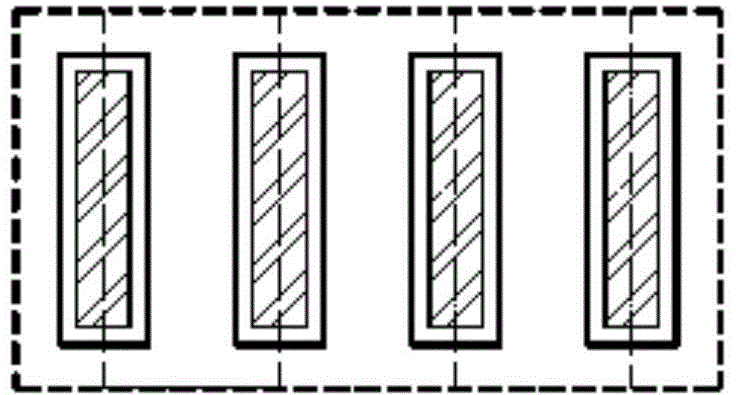

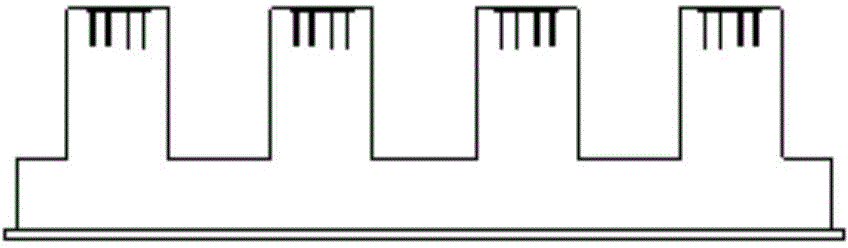

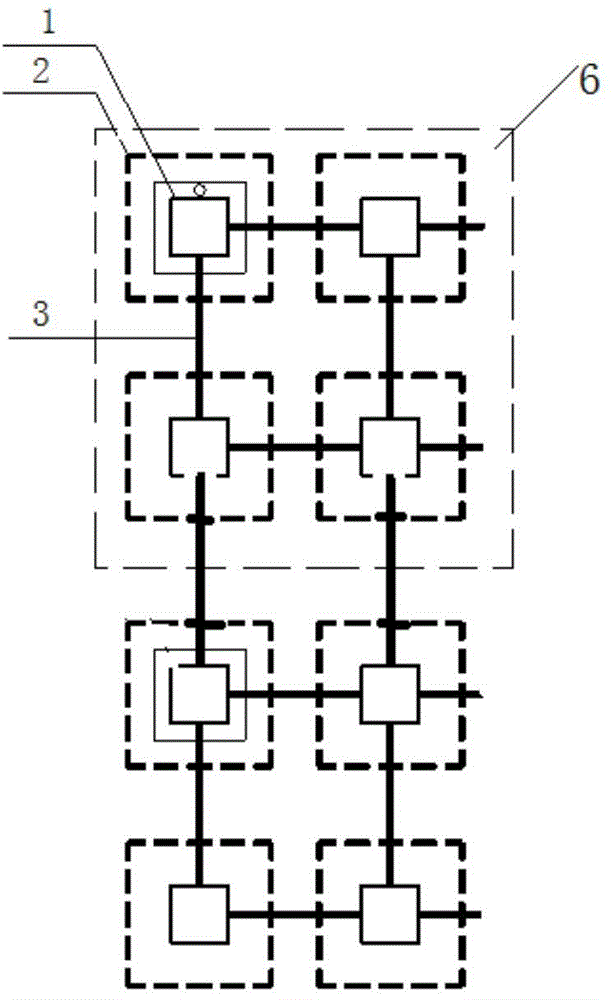

[0027] Figure 1, figure 2 and image 3 As shown, a number of high voltage reactor bearing units 6 are fixed in the base groove of the high voltage reactor, and each group of high voltage reactor bearing units 6 includes: four concrete foundations 1 are arranged in a square or a rectangle, and are respectively fixed on each concrete foundation 1 Steel concrete columns 2, the lower part of each steel concrete column 2 is surrounded by steel beams to form a square or rectangle, and the tops of two horizontal steel concrete columns 2 are connected by steel beams; the distance and quantity of concrete foundation 1 are based on the size of the high voltage reactor Adjustment, the concrete foundation 1, the steel concrete column 2 and the steel beam 3 are all prefabricated parts.

[0028] The steel beam 3 is an I-shaped channel steel, and the steel concrete colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com