High-concentration organic salt-containing wastewater treatment method adopting steam recompression technology

A technology for steam recompression and saline wastewater, which is applied in water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing processing costs and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings.

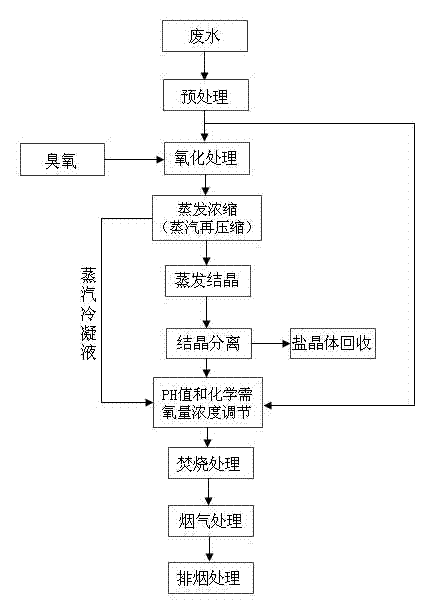

[0035] like figure 1 As shown, the method for treating high-concentration organic salt-containing wastewater using vapor recompression technology of the present invention includes the following steps.

[0036] The first step is to preprocess;

[0037] Use a filter screen to pre-treat the waste water by filtering residues to remove impurities and suspended solids in the waste water.

[0038] The second step is to carry out oxidation treatment;

[0039] The pretreated wastewater is sent into the oxidation tower, and at the same time, ozone is introduced into the oxidation tower, and the wastewater is oxidized by ozone, so that the content of organic matter in the wastewater is reduced to about 15%.

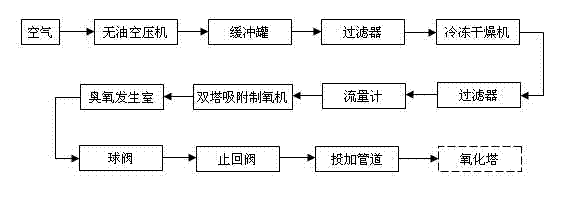

[0040] like figure 2 As shown in the figure, the equipment required for the preparation of ozone introduced into the oxidation tower includes an oil-free air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com