Automatic feeding machine for medical drip chambers

An automatic feeding and medical technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of lower production efficiency, stuck conveyor belt, complex structure, etc., to improve feeding accuracy, neatly arrange materials, and take out materials Efficient and precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

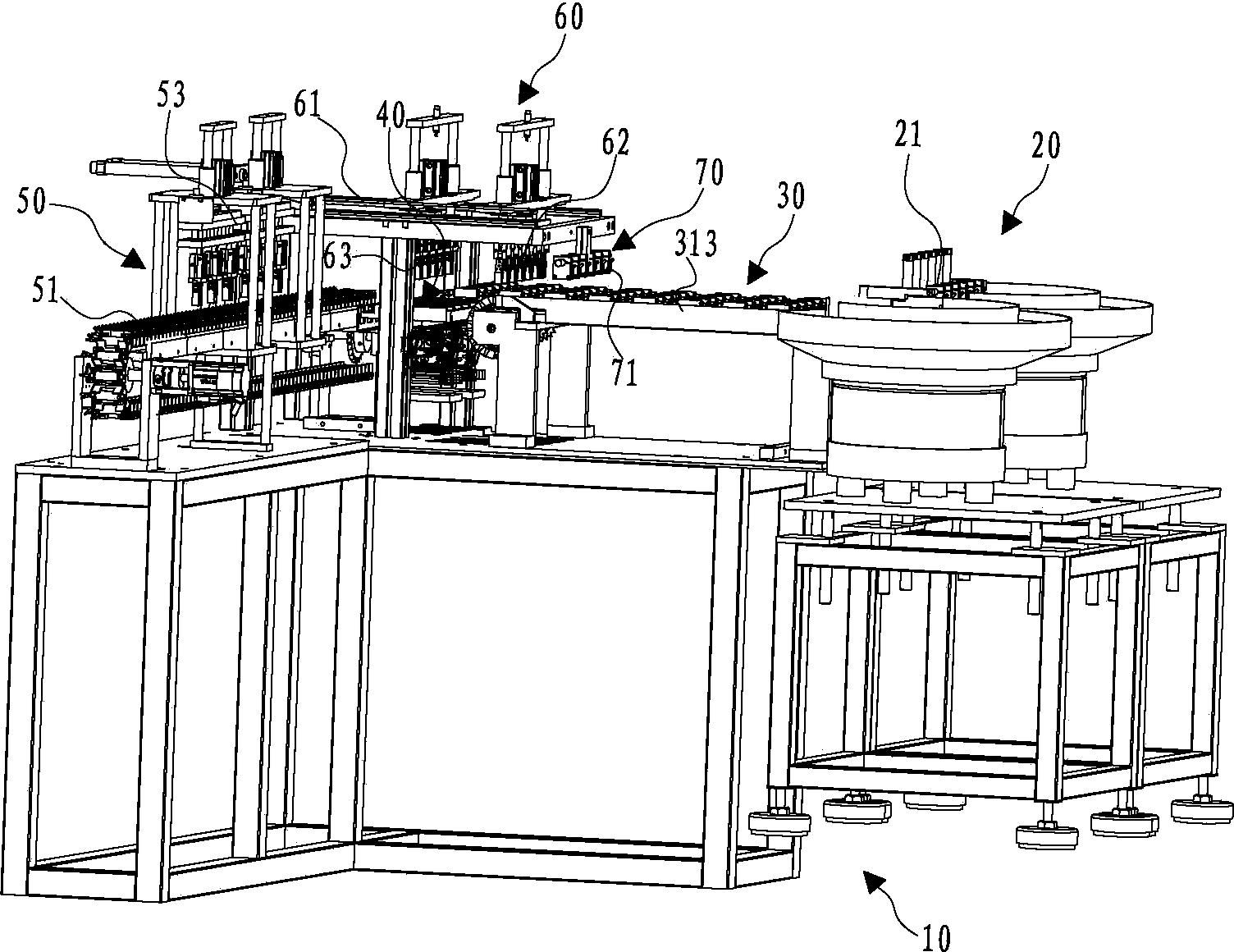

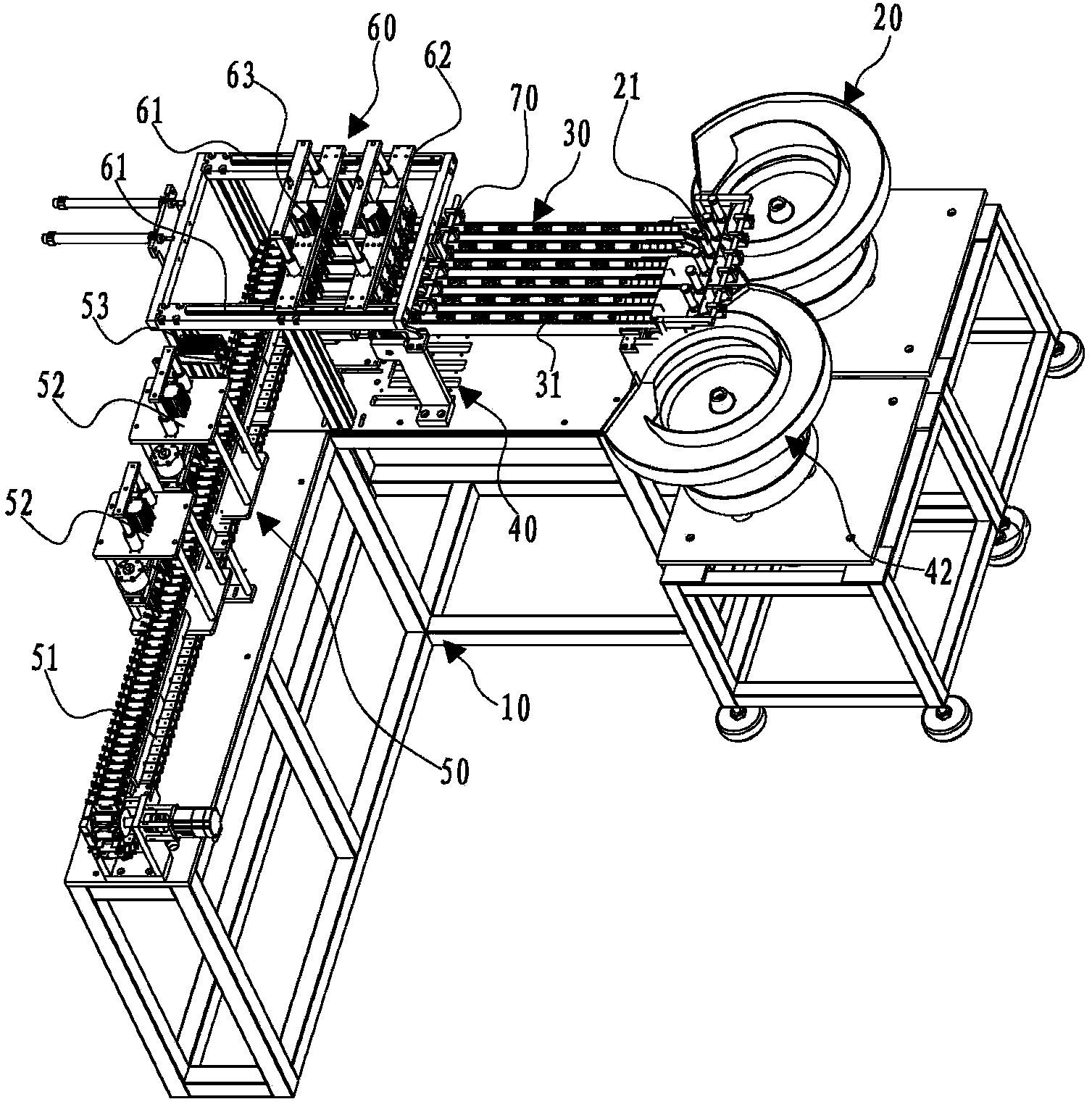

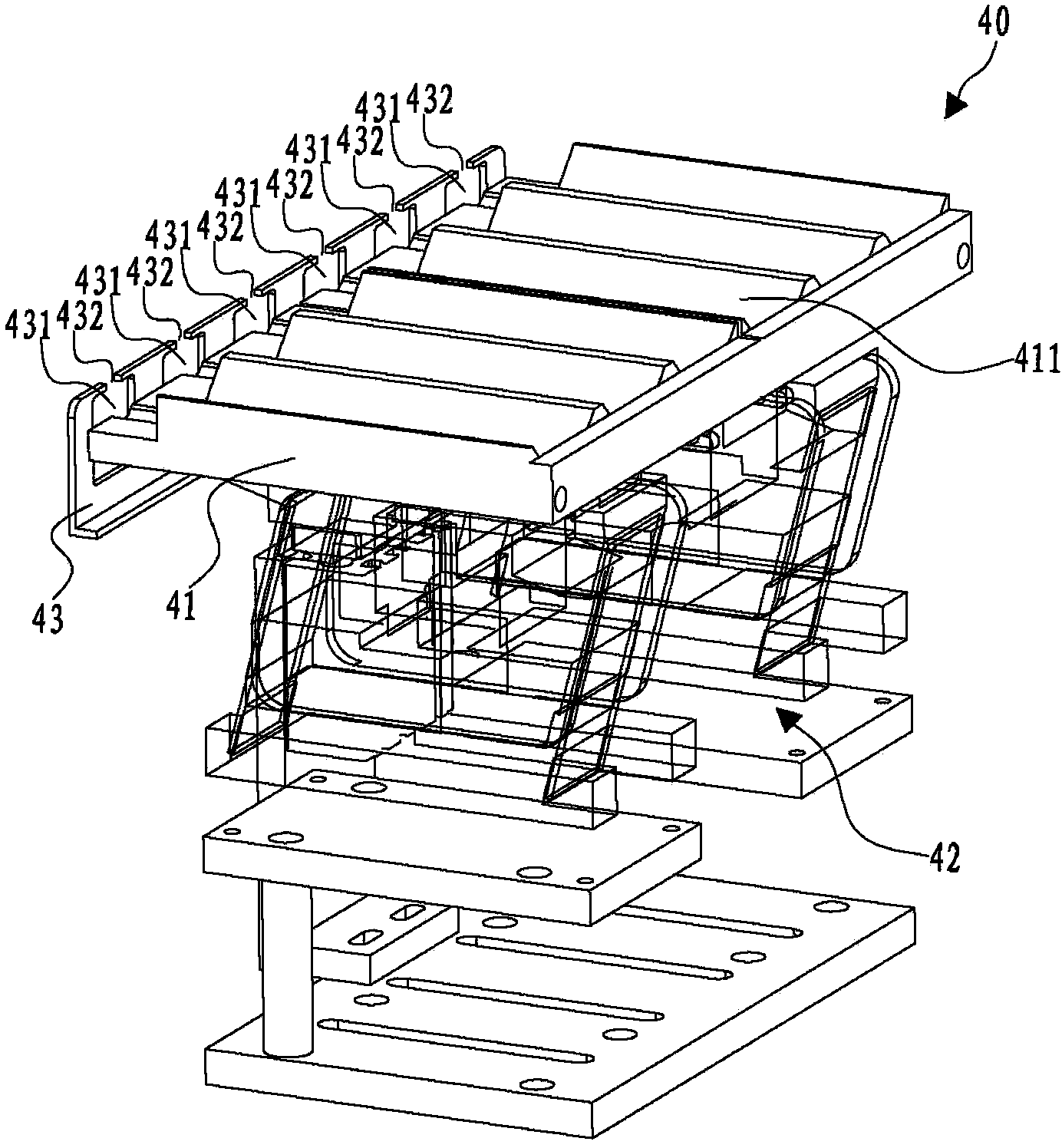

[0053] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of a preferred embodiment of the present invention, an automatic feeding device for a medical dropper, including a frame body 10, a vibrating plate 20 installed on the frame body 10, and a discharge conveying device 30 , leveling device 40 , assembly conveying device 50 and feeding device 60 .

[0054]Wherein, the output end of the vibrating plate 20 is connected to the input end of the discharge conveying device 30, the leveling device 40 is arranged at the output end of the discharging conveying device 30, and the assembly conveying device 50 is arranged at the output of the leveling device 40 At the end, the output end of the discharge conveying device 30, the leveling device 40 and Assemble conveyor 50 input A feeding and retrieving device 60 is erected above, and an induction device 70 is provided above the output end of the discharging conveying device 30 .

[0055] Wherein, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com