Plastic cement rough edge repairing machine

A repairing machine and burr technology, which is applied in the field of plastic product production, can solve problems such as excessive cutting, insufficient cutting, and high labor intensity, and achieve the effects of accurate repair, improved production efficiency, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

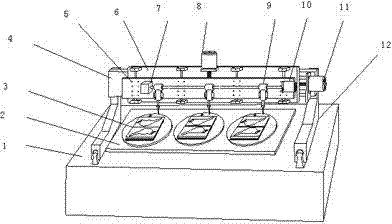

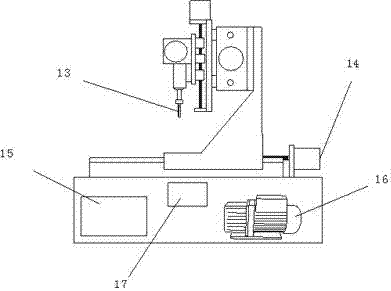

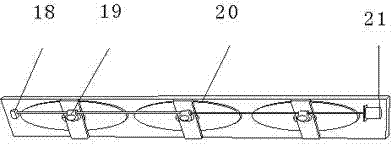

[0016] The plastic burr repairing machine uses the machine base (1) as the supporting body. The longitudinal sliding beam guide rail (12,) is installed on the machine base (1), and the horizontal sliding beam (6) is installed on the horizontal bracket (4) above the longitudinal sliding beam guide rail. The vertical sliding beam (5) is installed on the horizontal sliding beam, the blade (13) is locked on the tool rotation connector (9), the tool rotation angle detector (7) and the tool driving motor (10) and the tool rotation connector (9) ) installed on the vertical slide beam. The longitudinal sliding beam is driven by the motor (14) to reciprocate longitudinally; the horizontal sliding beam is driven to reciprocate horizontally by the motor (11); the vertical sliding beam is driven to reciprocate vertically by the motor (8). When the vertical slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com