Ultrasonic detection method for cracks in steel feet of suspension insulators

A technology of suspension insulator and detection method, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of narrow application range, low detection accuracy, inconvenient use, etc., and achieve the effect of reducing the loss of batch scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

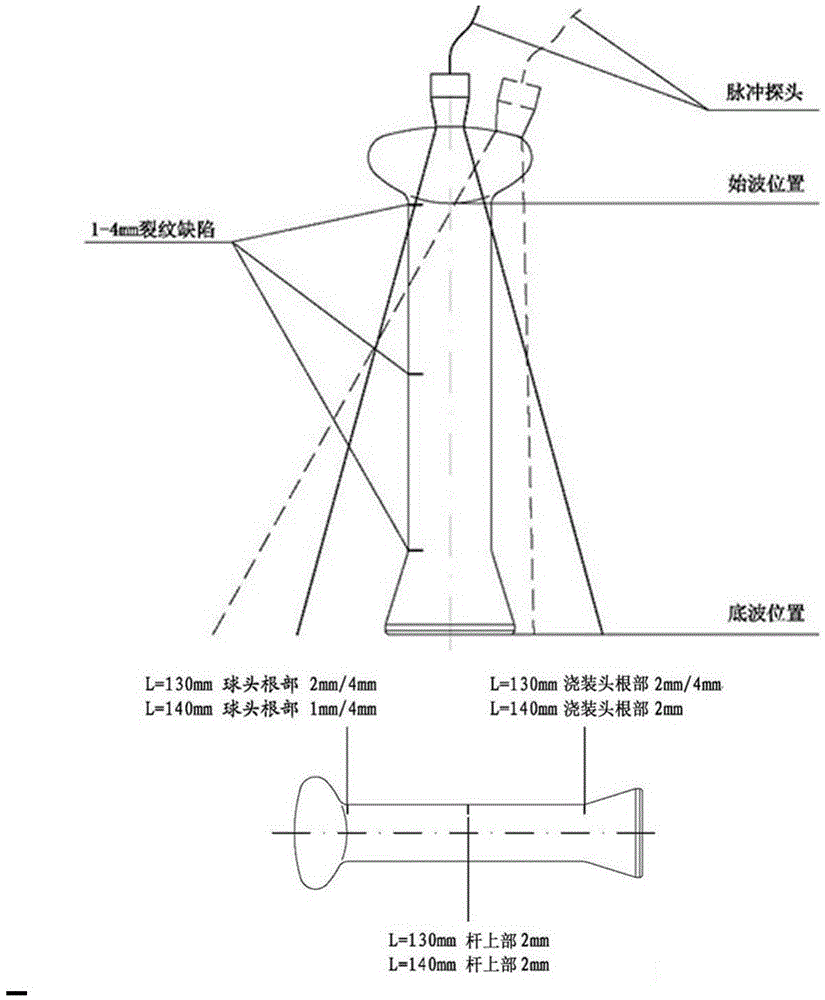

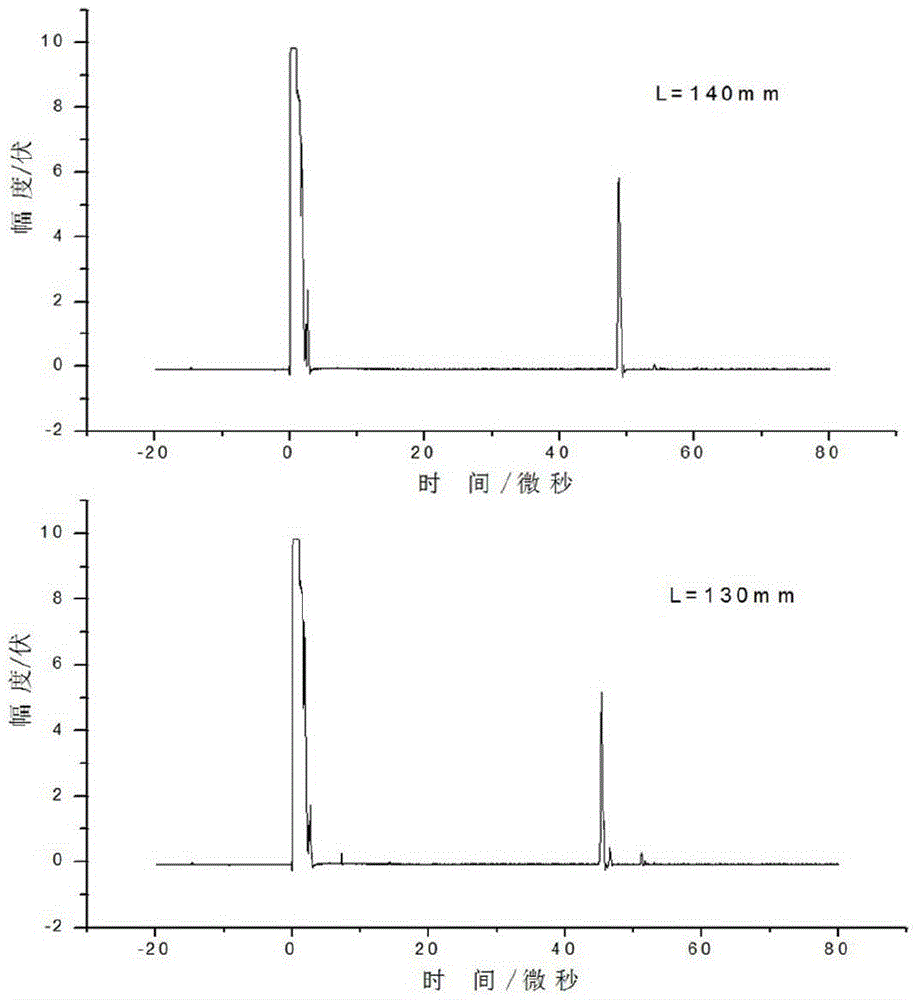

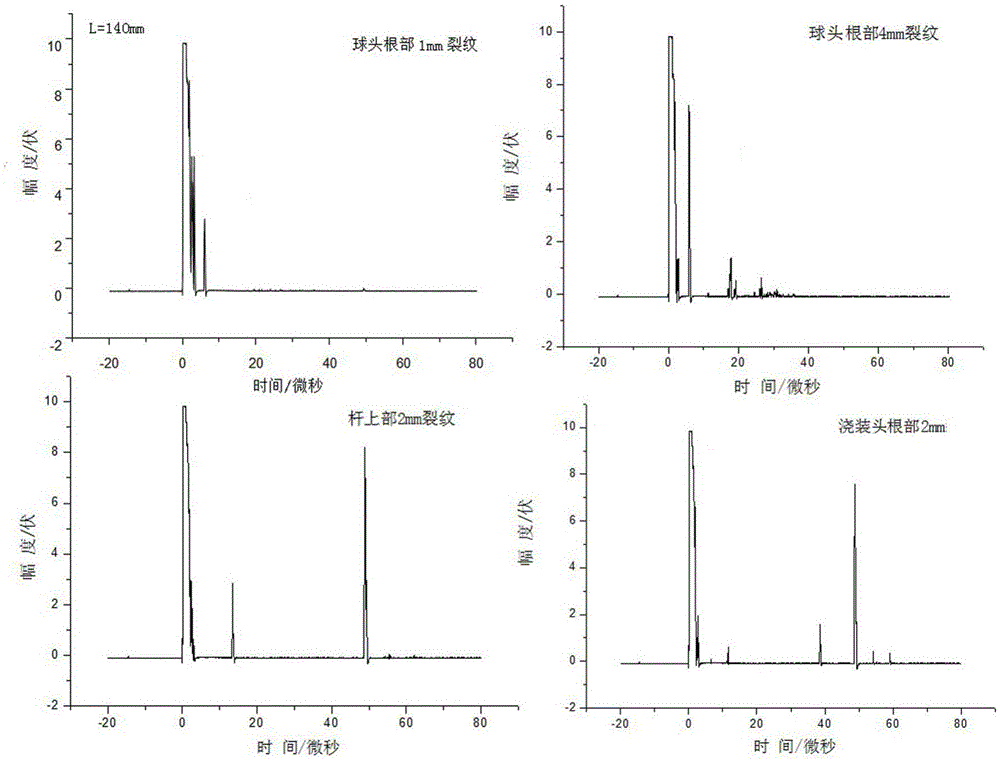

[0031] according to Figure 1~4 The detection method of the present invention is explained in detail. The 210kN insulator with a high tendency to crack defects is selected as the product to be inspected. The position of the artificial crack is as follows: figure 1 shown. The ultrasonic detection method for cracks in the steel feet of suspension insulators includes the following steps:

[0032] 1) Take 5 qualified suspension insulators with L=130mm and 6 qualified suspension insulators with L=140mm respectively as blank samples. Take 4 blank samples with L=140mm, the first and second ones are artificially cut cracks with depths of 1mm and 4mm respectively at the distance from the root of the ball head to the surface of the ball head at a distance of 16.5mm, and the third one is at the distance from the ball head to the top of the shaft. A crack with a depth of 2mm was manually cut at a distance of 38.0mm from the surface of the head, and the third crack was cut with a depth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com