Convex orifice burner

A burner and convex hole technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of complex assembly process, low combustion power, and many processed parts, so as to achieve less assembly process and complete combustion reaction , the effect of complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

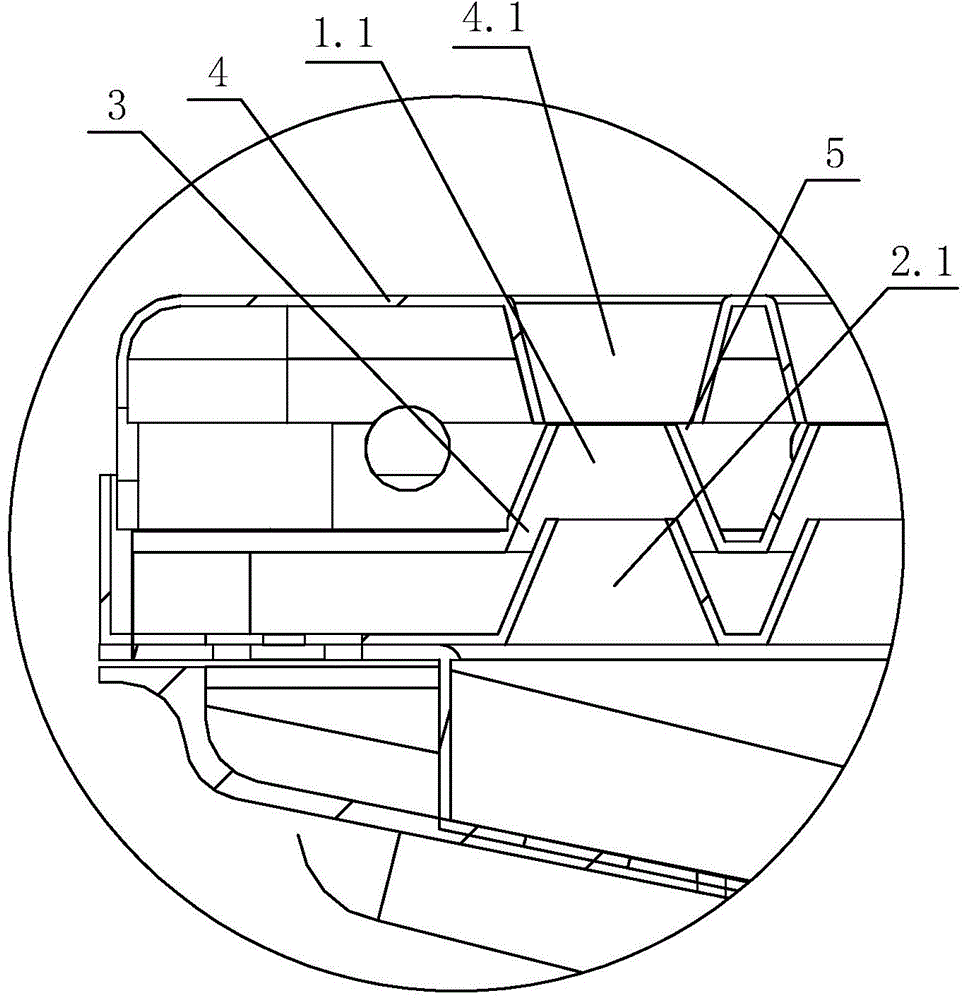

[0016] Such as Figure 1-4 As shown, a convex orifice burner includes an upper convex orifice plate 1 and a lower convex orifice plate 2 which are sealed and assembled into a cavity. The upper convex orifice plate 1 and the lower convex orifice plate 2 form a number of mutual Corresponding to the upper boss hole 1.1 and the lower boss hole 2.1, the opposite port of the upper boss hole 1.1 is sleeved outside the opposite port of the lower boss hole 2.1 to form an annular hole 3 therebetween. There is a rectification panel 4 assembled on the upper side of the upper convex hole plate 1, the rectification panel 4 forms a concave platform hole 4.1 corresponding to the upper convex platform hole 1.1, and the opposite port of the concave platform hole 4.1 is sleeved on the opposite port of the upper convex platform hole 1.1 Outside to form the annular hole two 5 between the two, the side wall of rectifying panel 4 offers some air intake through-holes 4.2. There are two sets of eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com