A thermostat for a heat exchange circuit

A thermostat and thermal circuit technology, applied in the mechanical field, can solve problems such as fluid leakage, low thermostat spring life, and high structural design requirements of the thermostat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The orientation nouns such as top, bottom, left, and right described in the present invention are all described according to the relationship between up, down, left, and right in the accompanying drawings;

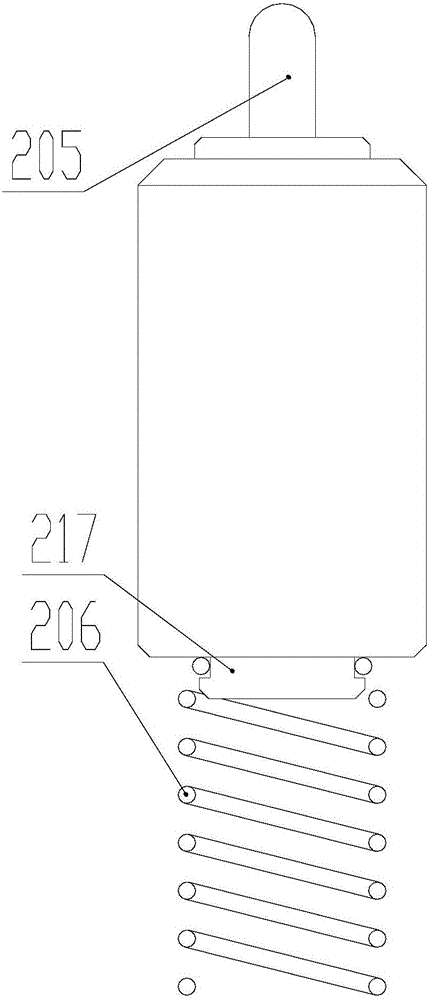

[0026] The initial deformation force of the first spring 203 in the present invention means that when the first spring 203 is compressed and deformed by the pressure of the push rod 205 so that the retaining ring 121 no longer bears the pressure exerted by the first spring 203, the first spring 203 under pressure.

[0027] The above definitions are applicable in all statements herein, and will not be repeated hereafter.

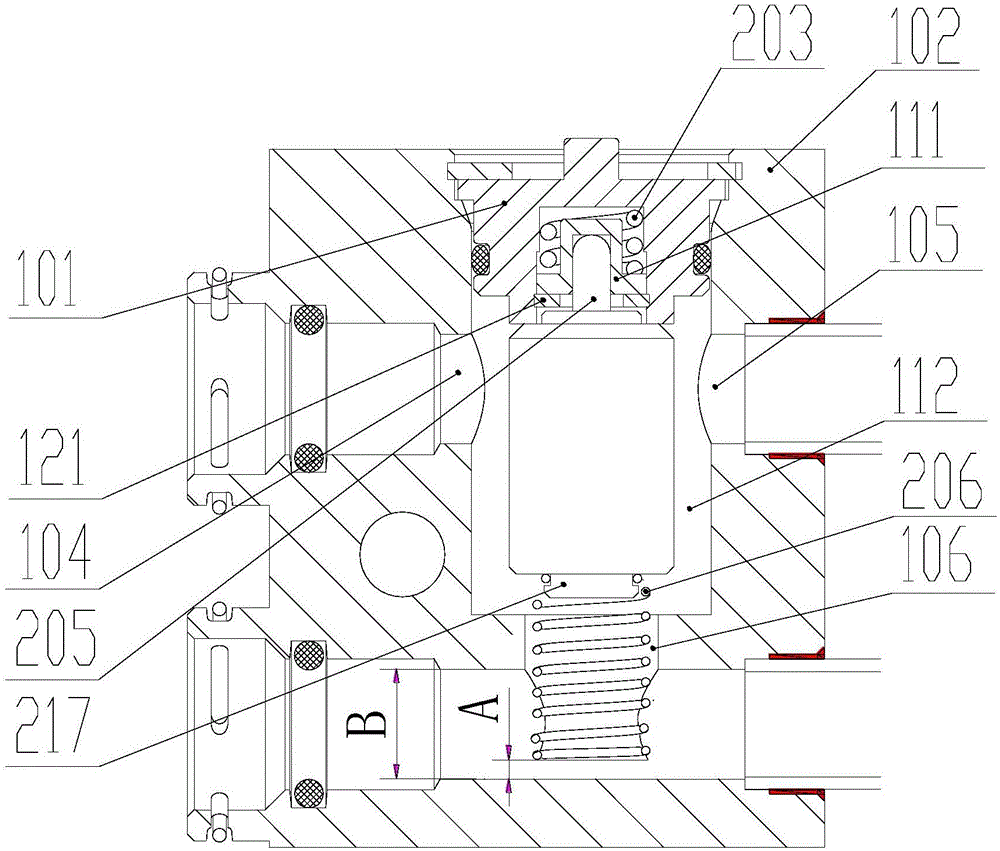

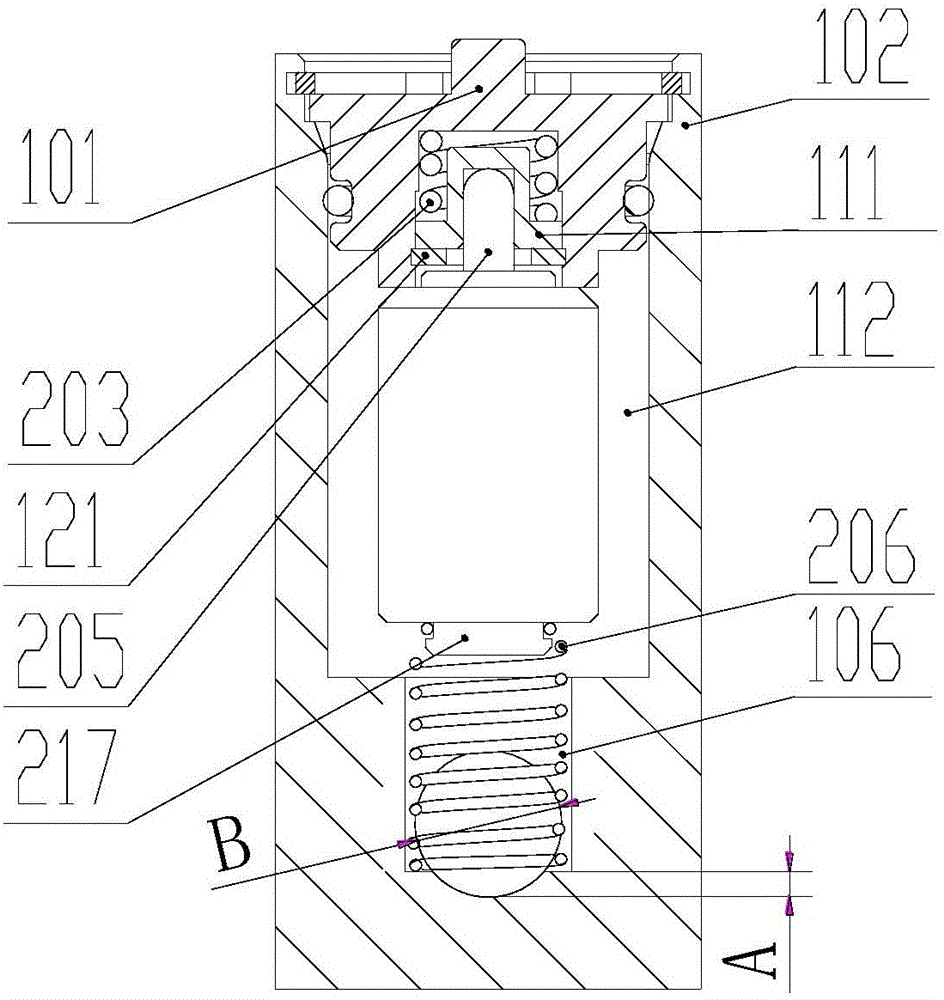

[0028] Such as Figure 1-Figure 5 As shown, in the thermostat embodiment of the present invention: the thermostat includes a valve body 102 provided with a cavity 112 and a thermodynamic element fitted in the cavity 112, and the thermodynamic element includes a thermosensitive substance The body and the push rod 205 slidingly installed on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com