A thermostat for a heat exchange circuit

A thermostat and thermal circuit technology, applied in the direction of valve operation/release device, gear lubrication/cooling, valve details, etc., can solve the problems of low thermostat spring life, fluid leakage, high structural design requirements of thermostat, etc. , to achieve the effect of reducing fluid leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] The orientation nouns such as top, bottom, left, and right described in the present invention are all described according to the relationship between up, down, left, and right in the accompanying drawings;

[0037] The initial deformation force of the first spring 203 in the present invention means that when the first spring 203 is compressed and deformed by the pressure of the push rod 205 so that the retaining ring 121 no longer bears the pressure exerted by the first spring 203, the first spring 203 under pressure.

[0038] The above definitions are applicable in all statements herein, and will not be repeated hereafter.

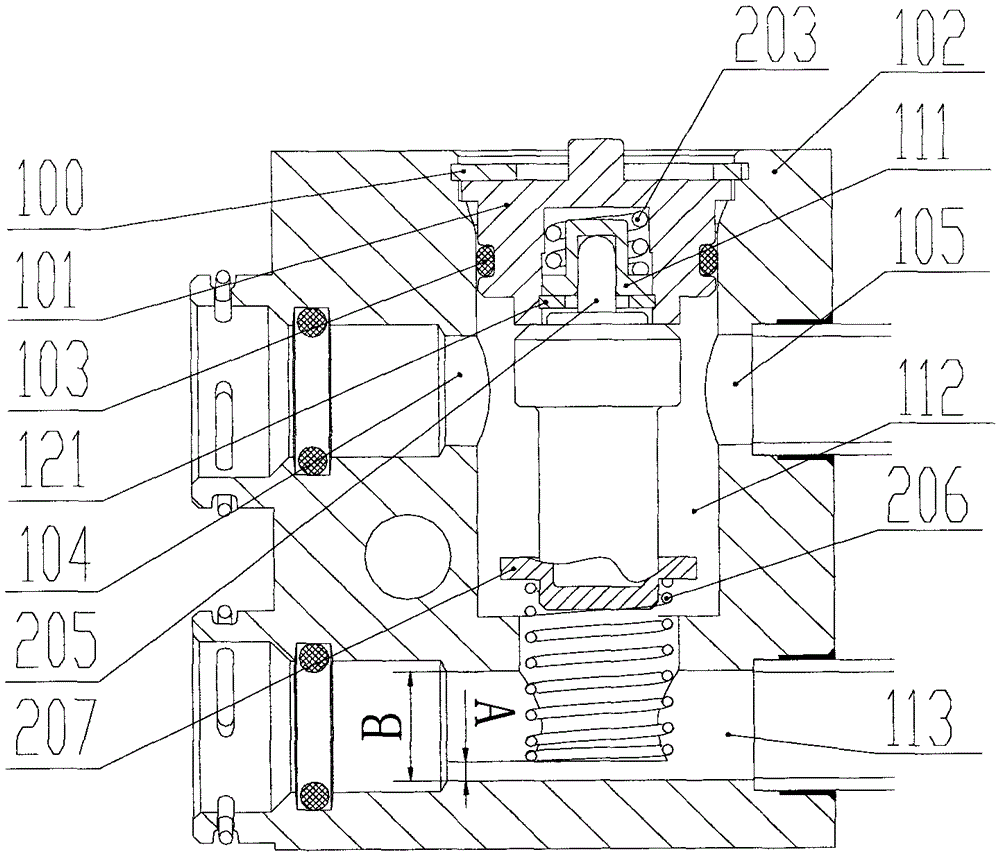

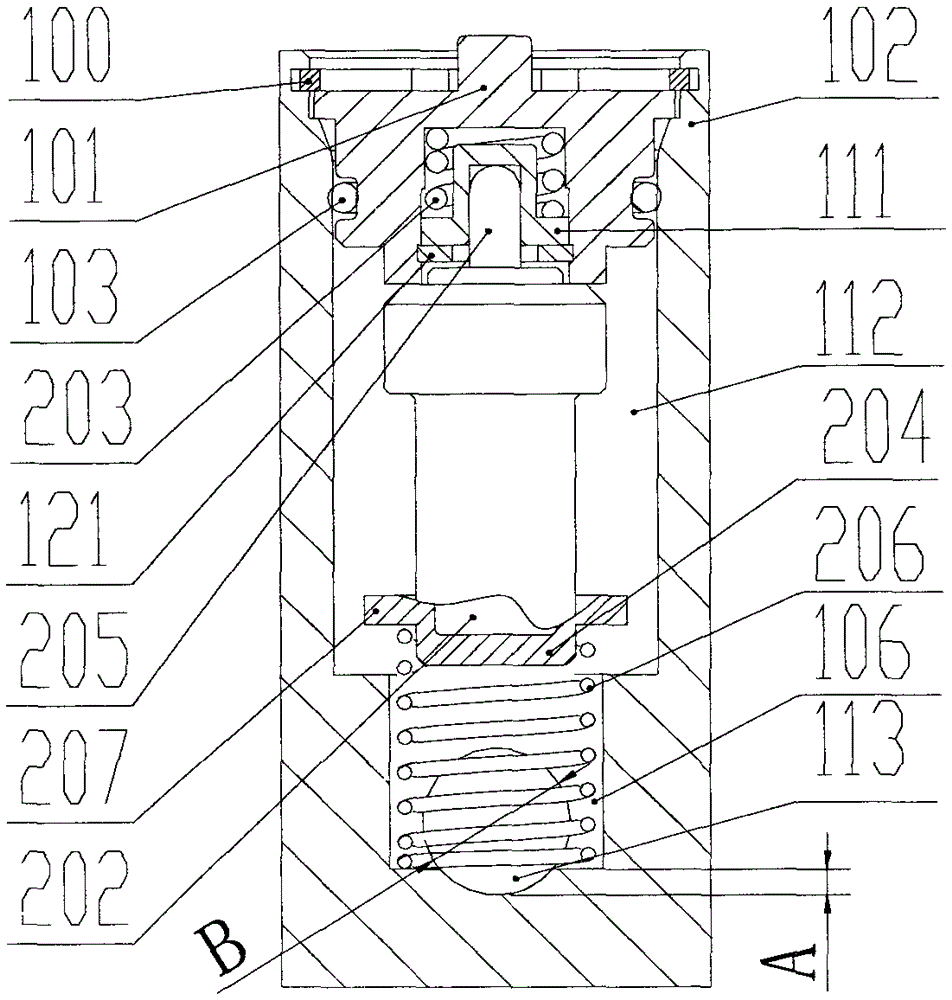

[0039] There are many ways to implement the specific thermostat, such as Figure 1-Figure 10 As shown, in various thermostat embodiments of the present invention: the thermostat includes a valve body 102 provided with a cavity 112 and a thermodynamic element fitted in the cavity 112, and the thermodynamic element includes a thermal sensor The bod...

Embodiment 1

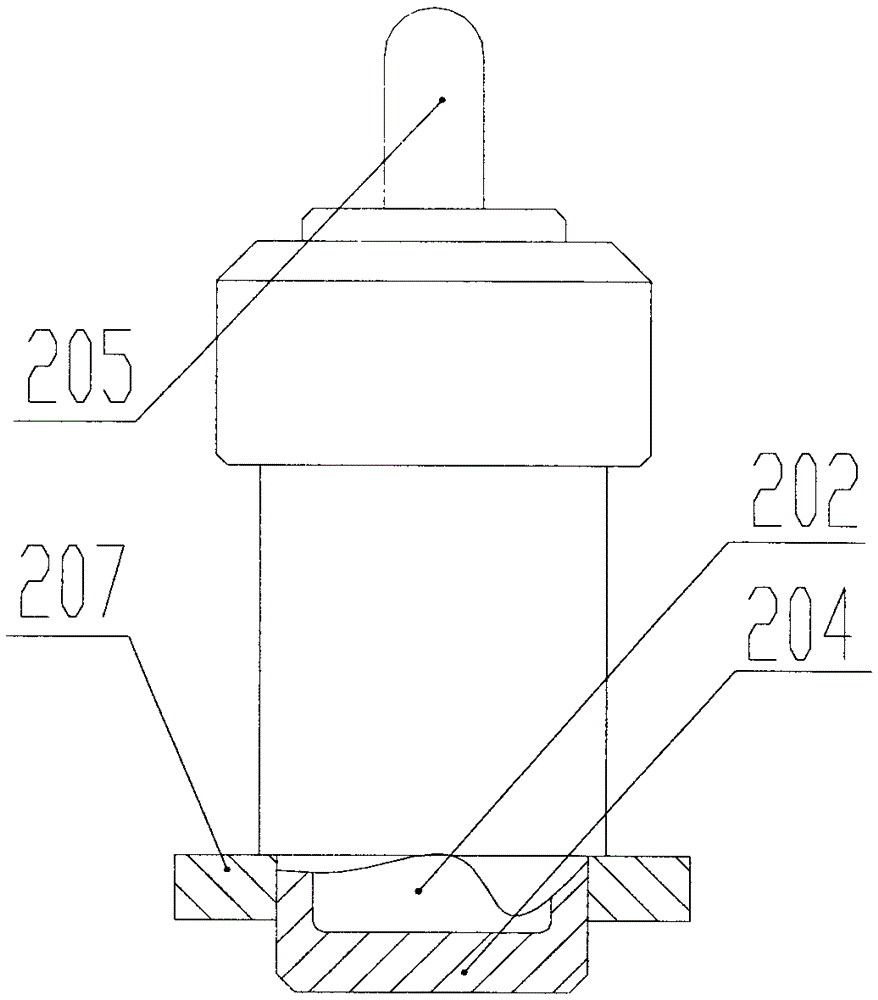

[0054] The difference between Embodiment 1 and Embodiments 2, 3, 4, and 5 lies in the position of the cover 207. As the distance between the cover and the second end of the body is different, the structural design requirements of the thermostat change accordingly. The cover 207 and the main body 204 are fixedly connected, and may also be an integral structure.

[0055] The second spring 206 can be in contact with the cover 207, the outer diameter of the end of the body 204 close to the third interface 106 is smaller than the inner diameter of the third interface 106, one end of the second spring 206 is in pressing contact with the cover 207, and the other end is in contact with the cover 207. The inner wall of the valve body 102 is press-contacted.

[0056] It can also directly abut against the second end of the body 204 , one end of the second spring 206 is in pressure contact with the end of the body 204 , and the other end is in pressure contact with the inner wall of the v...

Embodiment 5

[0060] The difference between Embodiment 5 and other embodiments is that a flow channel communicating with the third interface 106 is provided in the valve body of the thermostats of Embodiments 1-4. However, the third interface 106 of the thermostat valve body in Embodiment 5 needs to be externally connected to pipes connected to other devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com