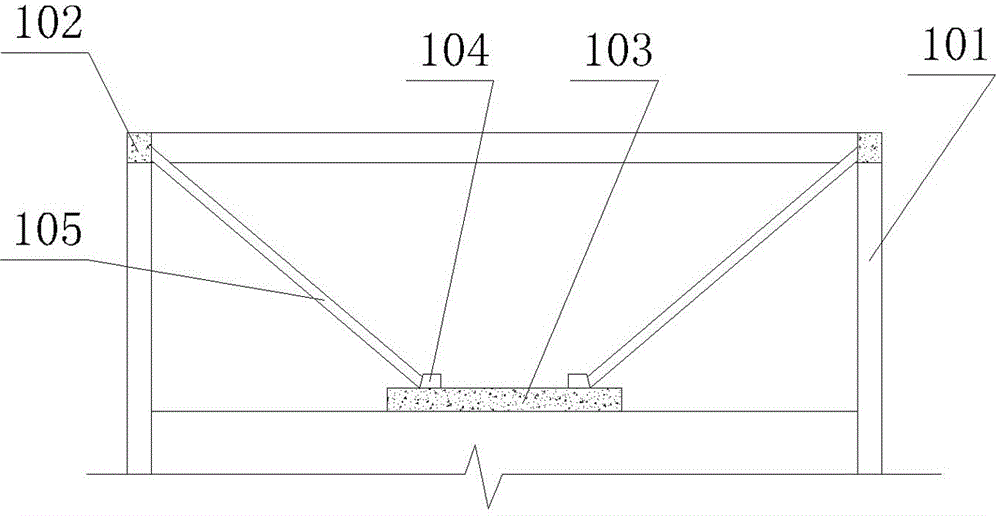

Corbel at the lower end of the inclined inner brace of the foundation pit support structure, manufacturing tools and construction method

A technology of foundation pit support and corbels, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of high cost, prolonging the overall construction period, and consuming large man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

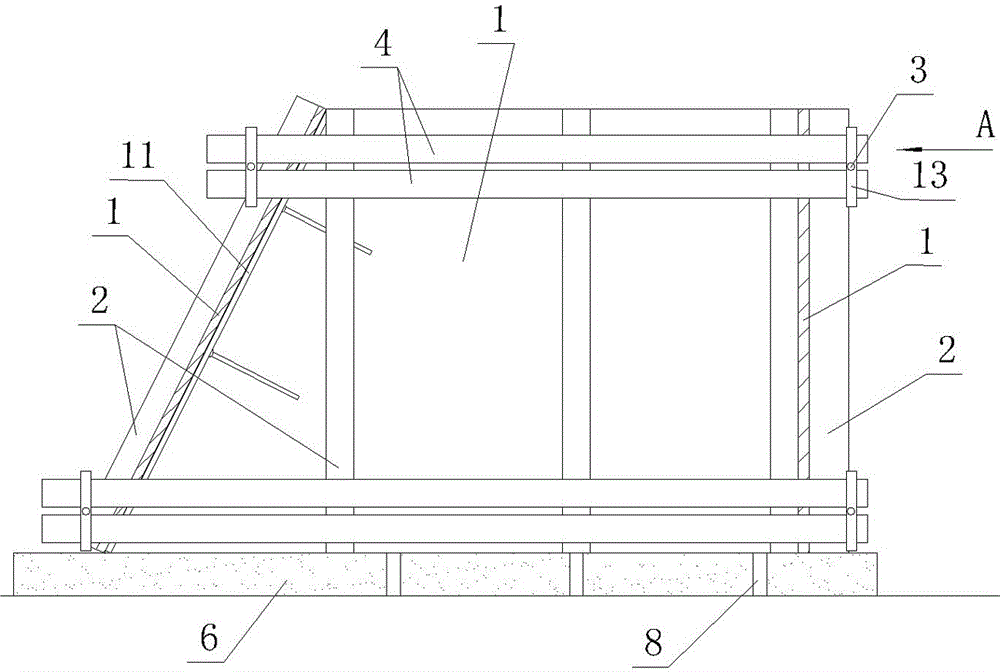

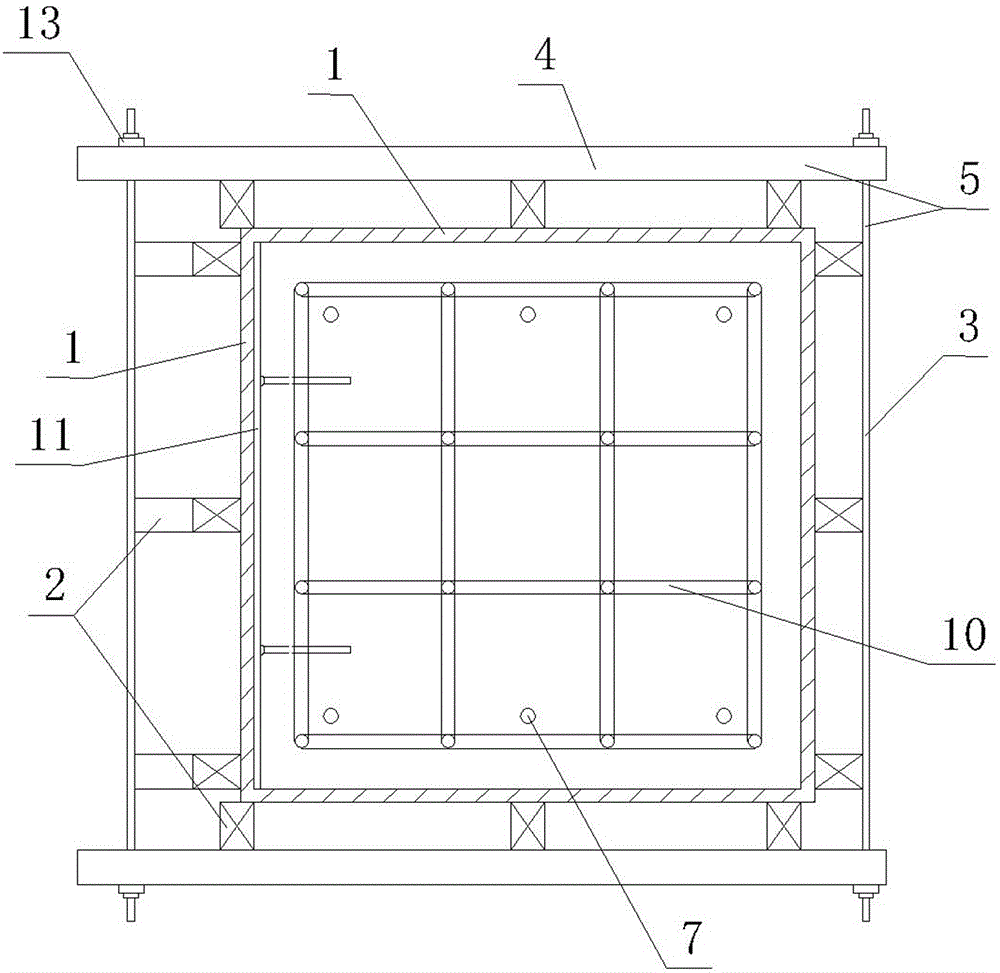

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the manufacturing tool of the corbel at the lower end of the oblique support of the foundation pit support structure of the present invention includes four side formworks 1, a plurality of square wooden corrugations 2, two steel plates made of pull bolts 3 and horizontal steel pipes 4 Structural hoop frame 5 and a bottom template 6. The square wooden flute 2 is fastened on the side template 1 by the steel structure hoop frame 5 . The bottom template 6 is provided with a through hole 8 through which the anchor bar 7 passes. Specifically, each steel structure hoop frame 5 includes two pull bolts 3 and four horizontal steel pipes 4, and the four horizontal steel pipes 4 are divided into two groups, which are respectively located on two side formworks 1 parallel to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com