Mercapto polyaniline and preparation method thereof

A polyaniline and sulfhydryl technology, applied in the field of polyaniline containing sulfhydryl and its preparation, can solve problems such as sulfhydryl oxidation, and achieve the effect of protecting sulfhydryl from being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention at first provides a kind of preparation method of polyaniline containing mercapto group, comprises as follows:

[0029] Step 1: Dissolving the aniline monomer containing mercapto group in an organic solvent to obtain a first mixed solution, the concentration of the aniline monomer containing mercapto group in the first mixed solution is 1 to 3 mol / L;

[0030] Step 2: dissolving the oxidant in the aqueous mineral acid solution to obtain a second mixed solution;

[0031] Step 3: Mix the first mixed solution obtained in step 1 with the second mixed solution obtained in step 2, and polymerize the aniline monomer containing mercapto group at the water-organic solvent interface to obtain a reaction product;

[0032] Step 4: The reaction product described in Step 3 is washed, washed with alcohol and dried to obtain polyaniline containing mercapto groups.

[0033] According to the present invention, the "interfacial polymerization" method is used to carry...

Embodiment 1

[0040] 2-aminothiophenol was dissolved in chloroform to obtain the first mixed solution, and the aniline monomer concentration in the first mixed solution was 1mol / L;

[0041] Dissolving ammonium persulfate in hydrochloric acid of 1mol / L to obtain a second mixed solution, the concentration of ammonium persulfate in the second mixed solution is 1mol / L;

[0042]The molar ratio is 2-aminothiophenol:ammonium persulfate=1:1, mix the first mixed solution and the second mixed solution, and place it statically at -10°C for 12 hours to obtain the reaction product;

[0043] The reaction product obtained above was washed with water, methanol and deionized water until the filtrate was colorless; then the product was vacuum-dried at a vacuum degree of 0.6 MPa and a drying temperature of 40° C. for 24 hours to obtain polyaniline containing mercapto groups.

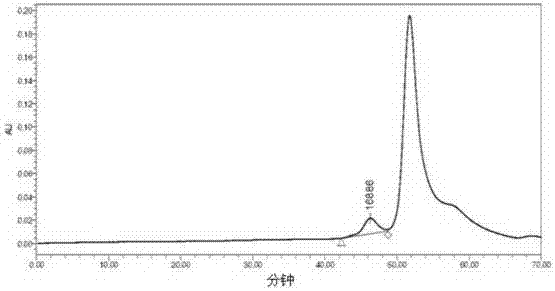

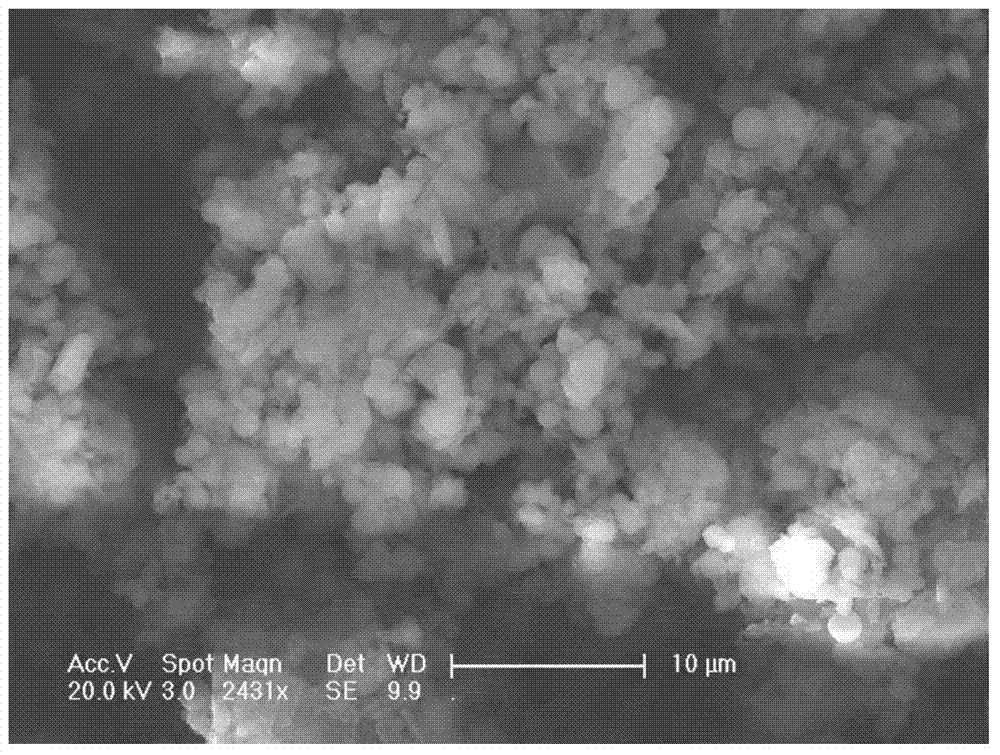

[0044] The polyaniline containing mercapto group prepared in the present embodiment 1 is detected, figure 1 Be the GPC curve figure o...

Embodiment 2

[0046] 3-aminothiophenol was dissolved in carbon tetrachloride to obtain the first mixed solution, and the aniline monomer concentration in the first mixed solution was 3mol / L;

[0047] Sodium persulfate is dissolved in the hydrochloric acid of 1mol / L, obtains the second mixed solution, the concentration of sodium persulfate in the described second mixed solution is 3mol / L;

[0048] The molar ratio is 3-aminothiophenol:sodium persulfate=1:3, mix the first mixed solution and the second mixed solution, and stand still at 10°C for 36 hours to obtain the reaction product;

[0049] The reaction product obtained above was washed with water, methanol and deionized water until the filtrate was colorless, and then the product was vacuum-dried for 36 hours at a vacuum degree of 0.9 MPa and a drying temperature of 50° C. to obtain polyaniline containing mercapto groups.

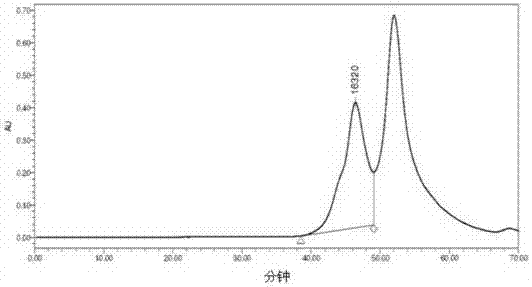

[0050] The polyaniline containing mercapto group prepared in this embodiment 2 is detected, Figure 4 Be the GPC cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com