Assembly tool for accurately locating large-size storage tank

A large-scale storage tank and assembly tooling technology, applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve the problems of low assembly efficiency, low assembly efficiency and quality, and poor precision, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

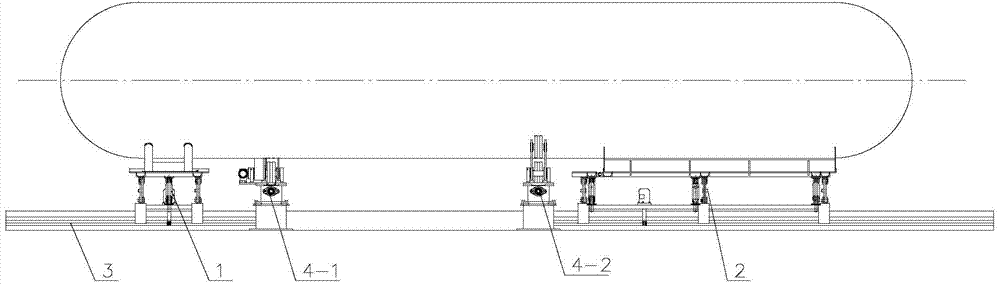

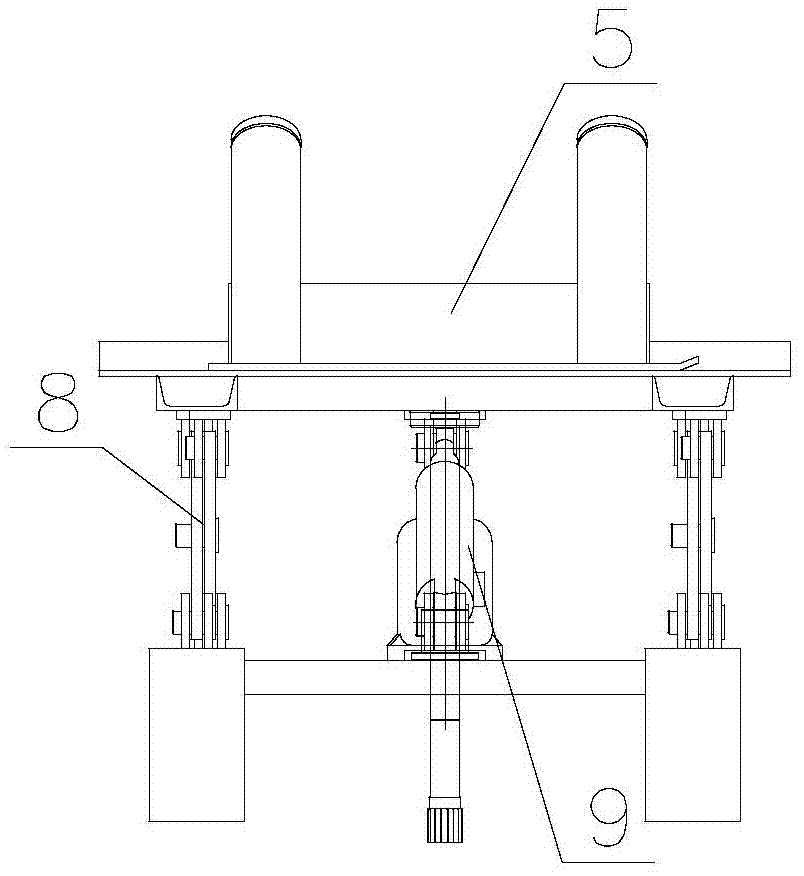

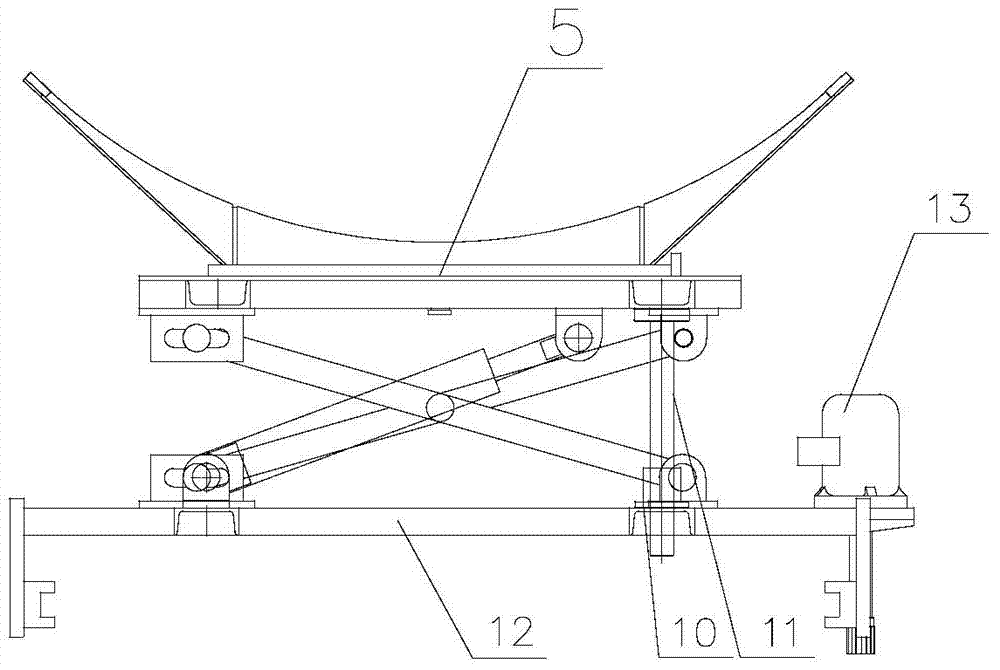

[0015] This embodiment provides an assembly tool for accurately positioning a large storage tank, and the structure is as Figure 1 to Figure 5 As shown, it is mainly composed of a pin seat lifter 1, a V seat lifter 2 and a supporting roller frame 4 arranged on the base assembly 3. The base assembly 3 includes a base and a linear guide rail, and the linear guide rails are fixed and installed on both sides of the base in parallel; The pin seat lifter 1 includes a pin seat 5 and a pin seat lifting mechanism. The pin seat 5 is fixedly installed on the top of the pin seat lifting mechanism. The bottom of the pin seat lifting mechanism is placed on a linear guide rail through a pin seat traveling wheel. The pin seat traveling wheel is driven by a motor. The speed reducer 13 is driven, and the pin seat lifting mechanism is driven by cylinder lifting; the V seat lifter 2 includes a V seat lifting mechanism and a V seat positioning card 6. The V seat positioning card 6 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com