Partition net for improving pollution-proof capacity of roll-type membrane component

A roll-type membrane and module technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as membrane flux reduction, pollution, separation membrane failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

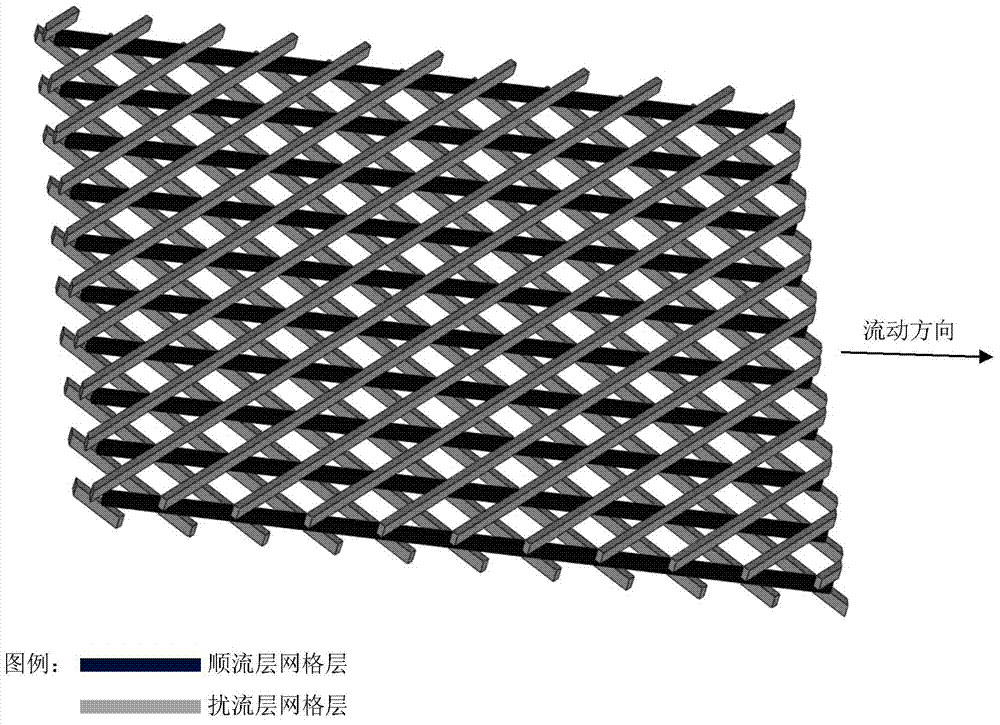

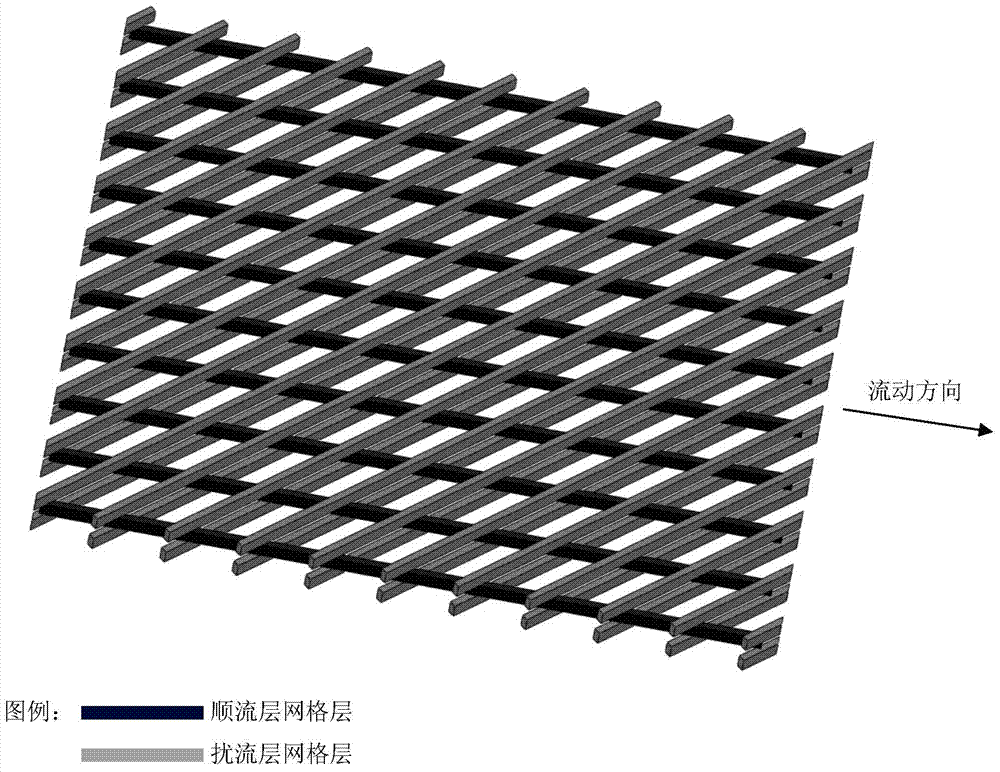

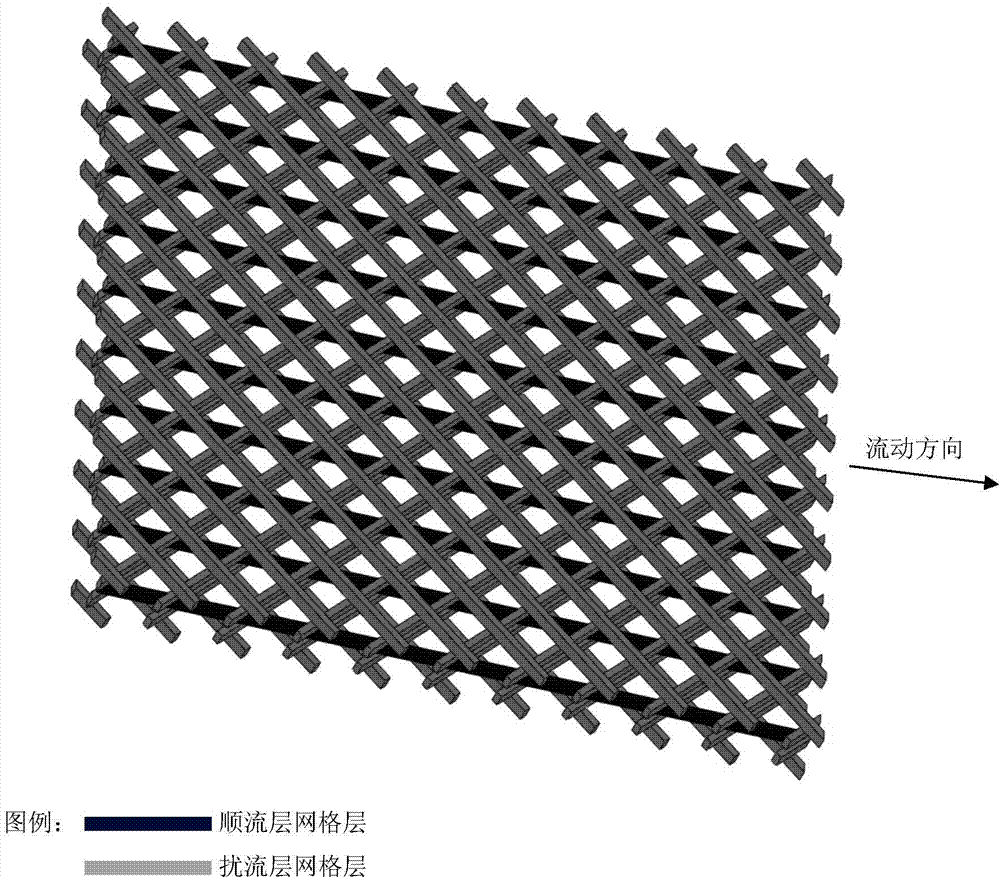

[0022] figure 1 -4 shows the structural schematic diagrams of the partition nets according to the first to third embodiments of the present invention respectively. The use of the spacer of the present invention in the spiral wound membrane module is similar to that of the commonly used spacer at present, but the spacer of the present invention has a requirement for the installation direction, that is, the direction of the flow path of the middle layer of the spacer must be in line with the flow direction of the raw material fluid unanimous.

[0023] figure 1 The shown screen according to the first embodiment of the invention comprises a single flow-disrupting layer arranged between flow-current layers. The downstream layer includes downstream mesh strips 101 arranged in parallel along the flow direction. The spoiler comprises spoiler mesh strips 102,103. The mesh strips 102 or 103 in each baffle layer are parallel to each other and at an angle to the flow direction. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com