A gas-water back-flushing device for tubular sintered membrane filter

A technology of filter and sintered membrane, which is applied in the field of sewage purification and treatment. It can solve the problems of incomplete backflushing, increased impact and leakage of filter tubes, etc., and achieve the effects of uniform backflushing, reduced impact force, and reduced height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

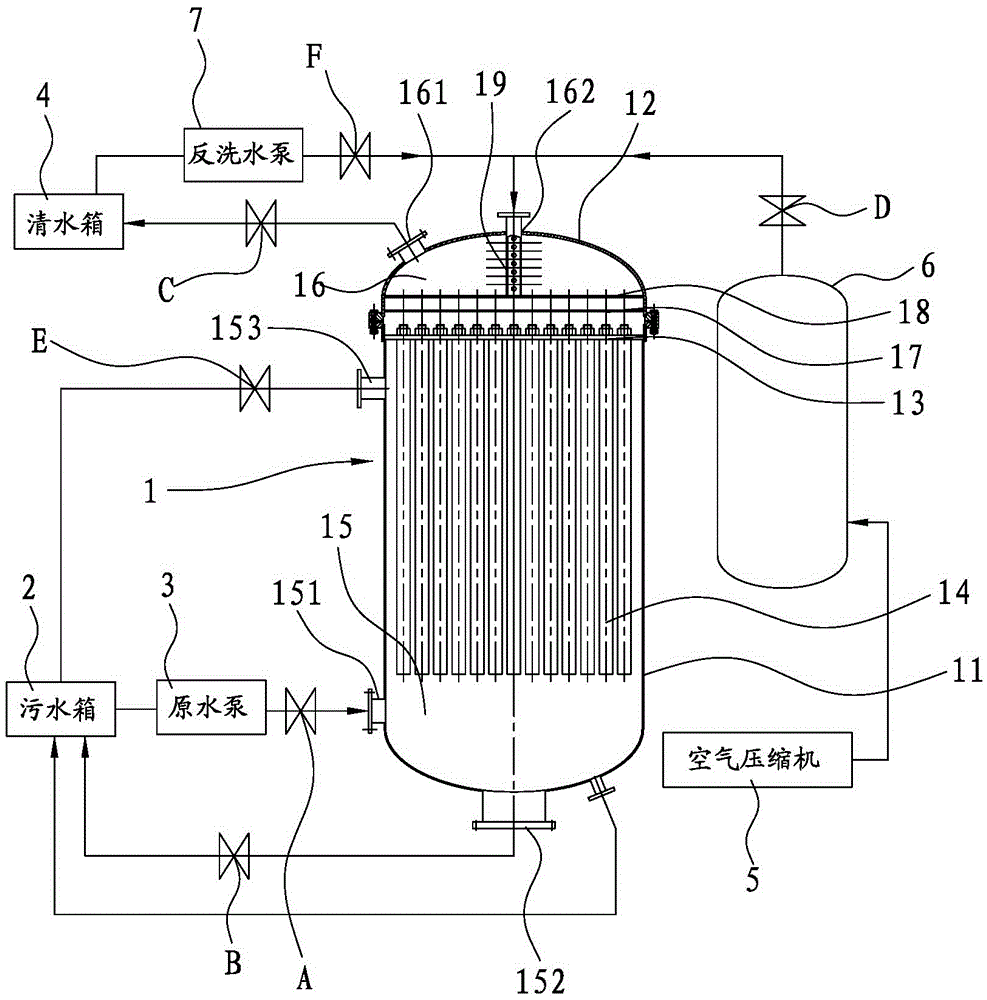

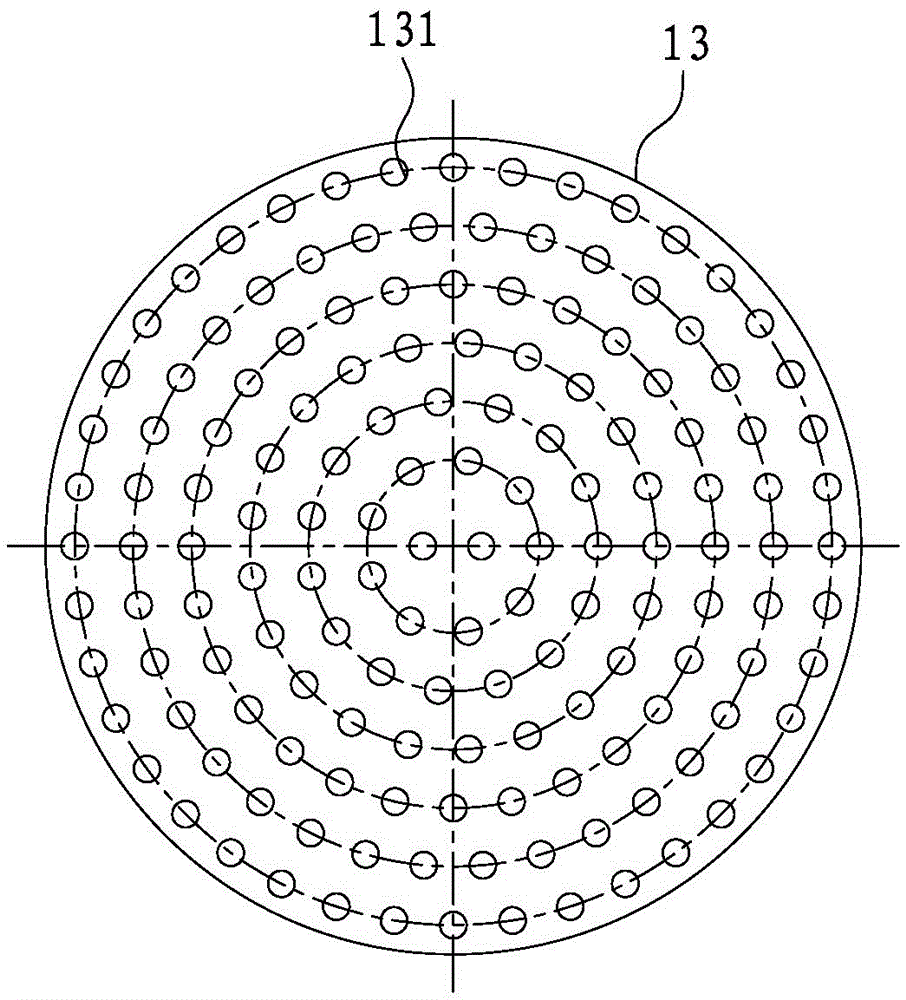

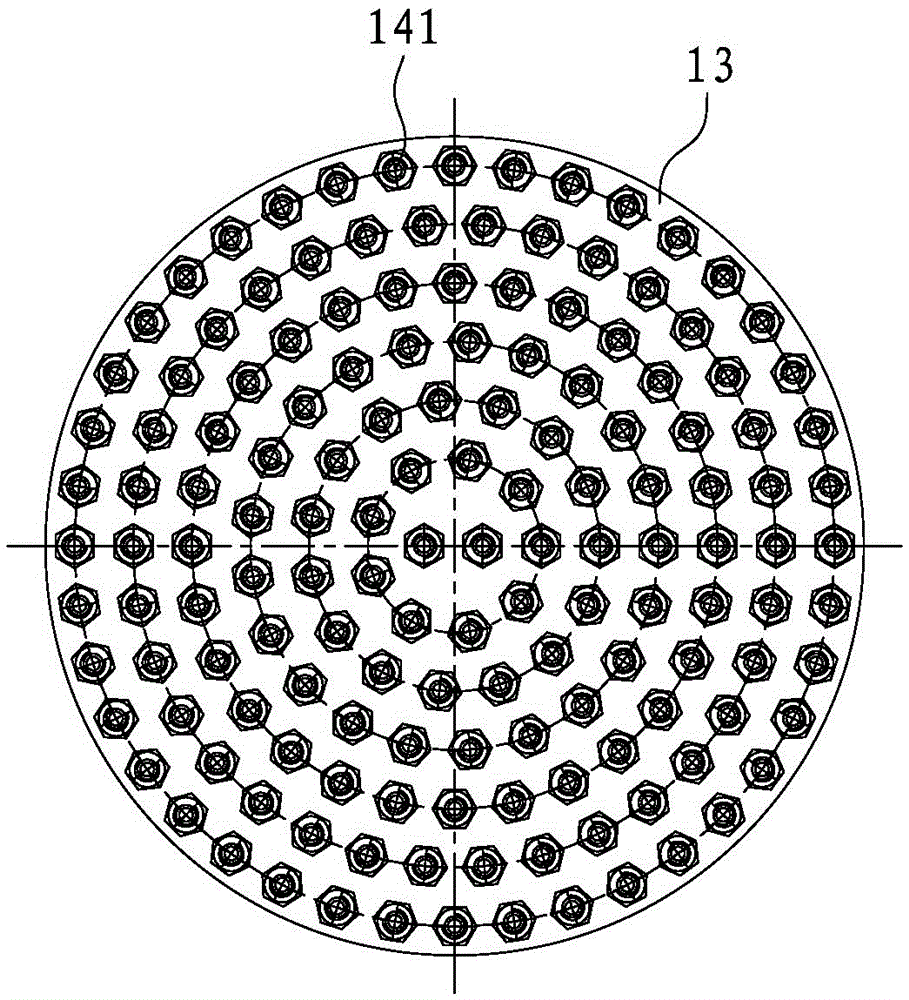

[0029] What the present invention discloses is a kind of air-water backflushing device for tubular sintered membrane filter, such as Figure 1 to Figure 6 Shown is a preferred embodiment of the present invention. The filter 1 includes a housing, which can be composed of a cylinder body 11 and a cover plate 12 that are covered with each other. A filter tube connecting plate 13 is installed in the housing, and the filter tube connecting plate 13 is provided with a Several installation holes 131, each installation hole 131 is fixedly installed with a sintered film tube 14. The filter tube connection plate 13 divides the inner space of the housing into two chambers, the sewage water inlet chamber 15 and the backflushing chamber 16, the sintered membrane tube 14 is located in the sewage water inlet chamber 15, and the sintered membrane T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com