Home pressing device, home pressing control method and wiring machine

The technology of a local pressure device and a local pressure component is applied in the field of connecting machine, local pressure device, and FPC hot pressing on soft film, which can solve the problems of low local pressure efficiency of filmsensor and achieve the effect of improving local pressure efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

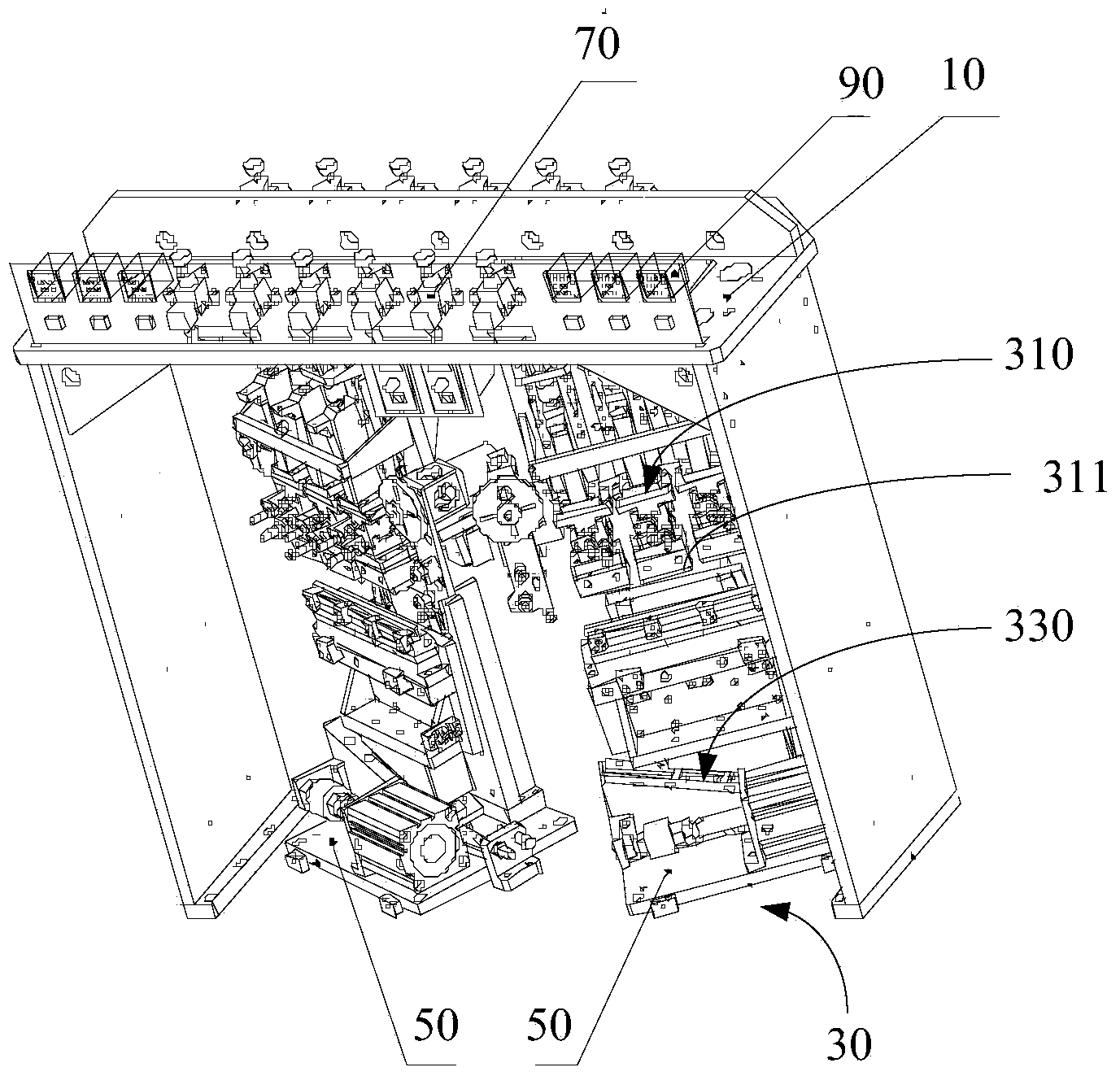

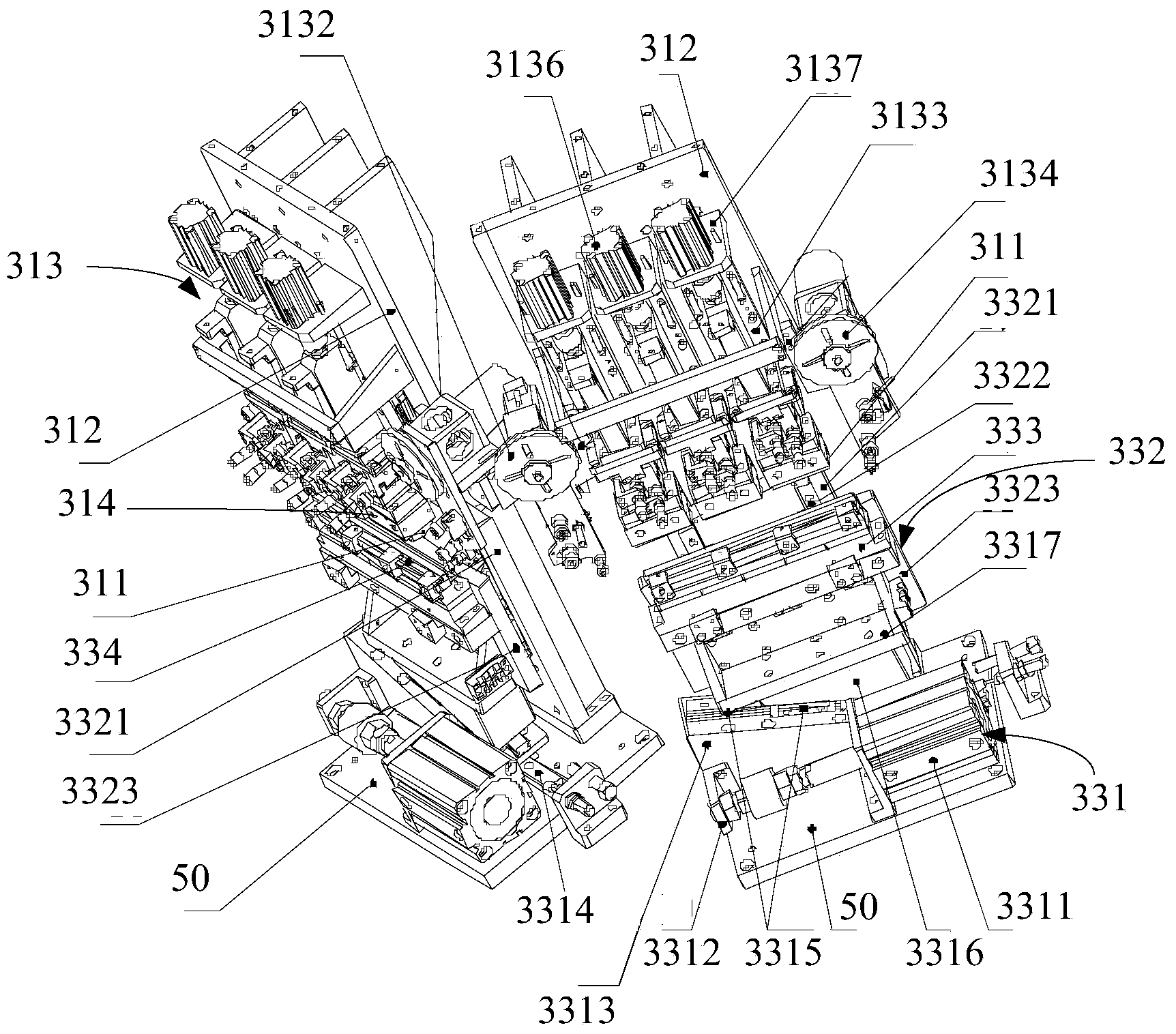

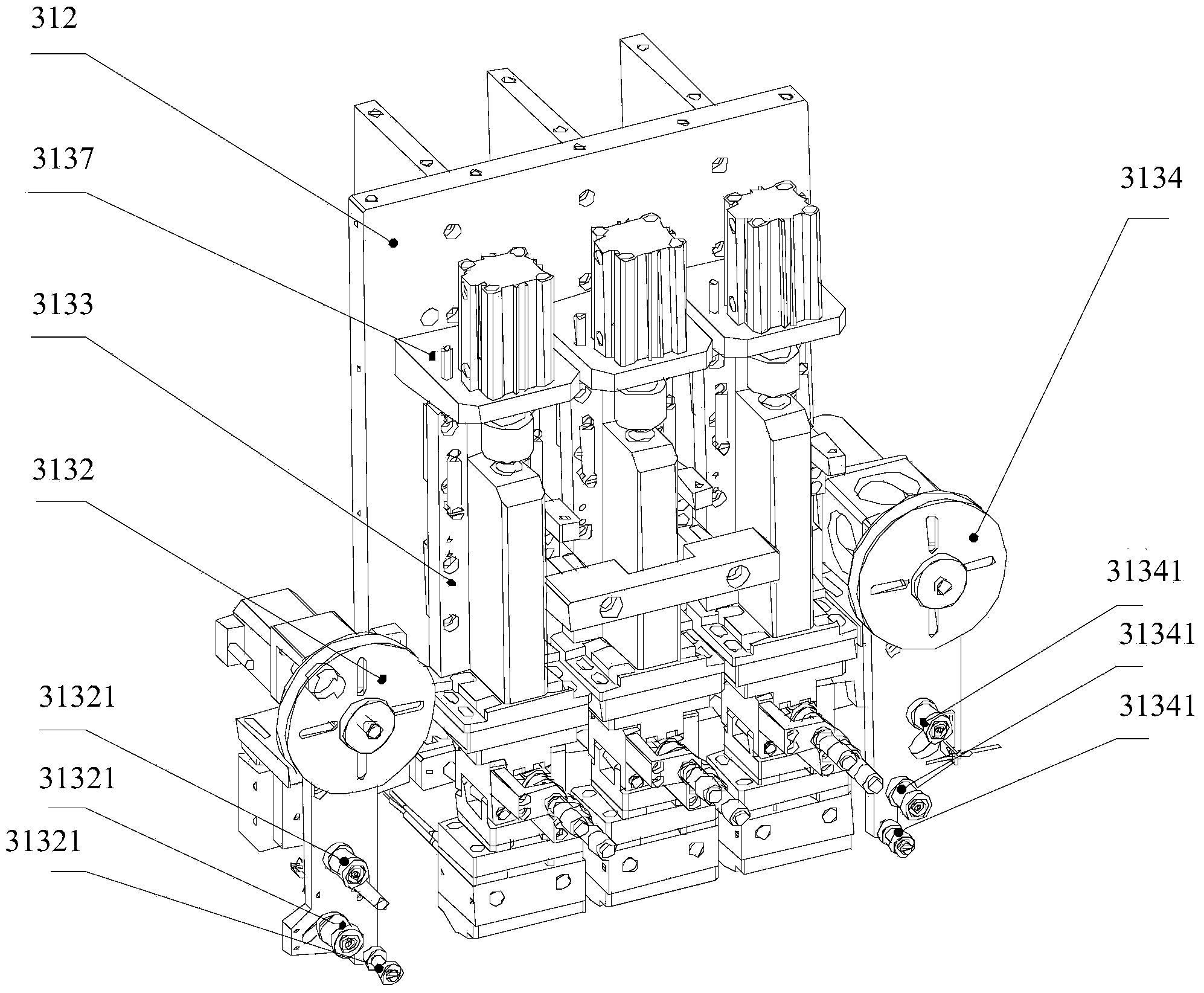

[0038] Such as figure 1 As shown, in one embodiment, a kind of present pressure device comprises:

[0039] support frame 10;

[0040] Several pressure components 30 are installed in the support frame 10;

[0041] The bottom surface fixing plate 50 is used for fixing on the pressure assembly 30;

[0042] Fixture (not shown), used to place the film sensor to be processed;

[0043] Wherein, the number of pressure components 30 will match the number of steps of the film sensor to be processed.

[0044] In this embodiment, since the steps on the film sensor correspond to different heights, the number of steps in the film sensor is used to perform several stages of pressure on the film sensor to complete the pressure on each film sensor. Specifically, the film sensor to be processed has two steps, which respectively correspond to different heights. Therefore, two pressure components 30 are set to perform segmental pressure on the film sensor, and each pressure component 30 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com