Hooking test device of location grids of reactor fuel assembly

A fuel assembly and spacer grid technology is applied in the field of reactor fuel assembly spacer grid out-of-core test devices, and can solve the problems of spacer grid damage, affecting the economy of nuclear power plants, affecting the safety of nuclear power plants, and the like, and reducing the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

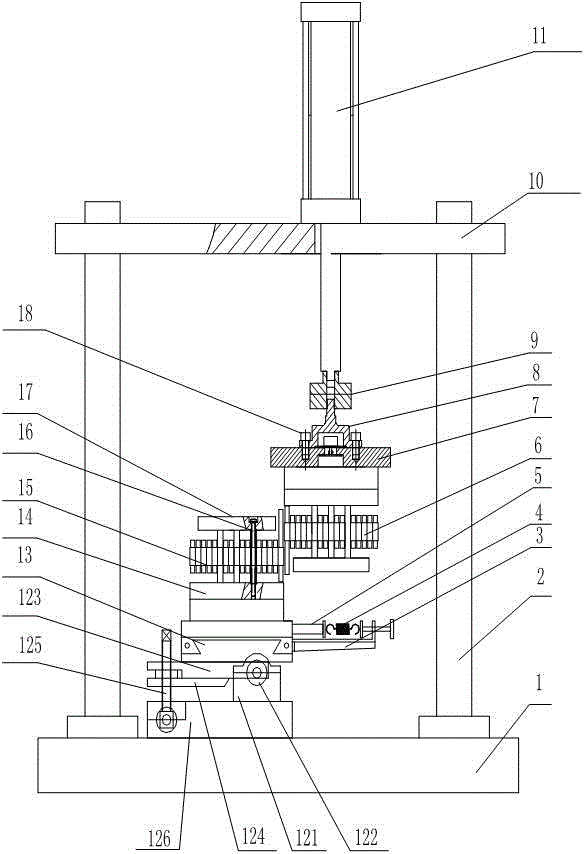

[0023] Such as figure 1As shown, a hooking test device for a reactor fuel assembly positioning grid of the present invention includes a frame bottom plate 1, and the frame bottom plate 1 is fixed on a plane. As an experimental platform, a column 2 is arranged on the frame bottom plate 1, The column 2 is used as the supporting part of the upper gravity, and is also a guide mechanism for adjusting the upper and lower positions of the frame top plate 10. A horizontal base plate 126 is installed on the frame bottom plate 1, and a bearing seat 121 is installed on the horizontal base plate 126. Bearing 122 is installed, and bearing 122 is connected with bearing pressure plate 123, and bearing pressure plate 123 can rotate around bearing 122, and bearing pressure plate 123 is used as the basic part of bearing horizontal sliding mechanism 13, and the bottom of bearing pressure plate 123 is equipped with inclination adjustment plate 124, and the inclination The adjusting plate 124 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com