Aluminum slab pit heating furnace with soaking function

A pit-type and heating furnace technology for aluminum slabs, which is applied to the maintenance of heat treatment furnaces and heating chambers, lighting and heating equipment, etc. The heat transfer effect is not obvious, etc., to achieve the effect of improving the performance of synchronous temperature rise, ensuring synchronous temperature rise, and shortening the soaking and heating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

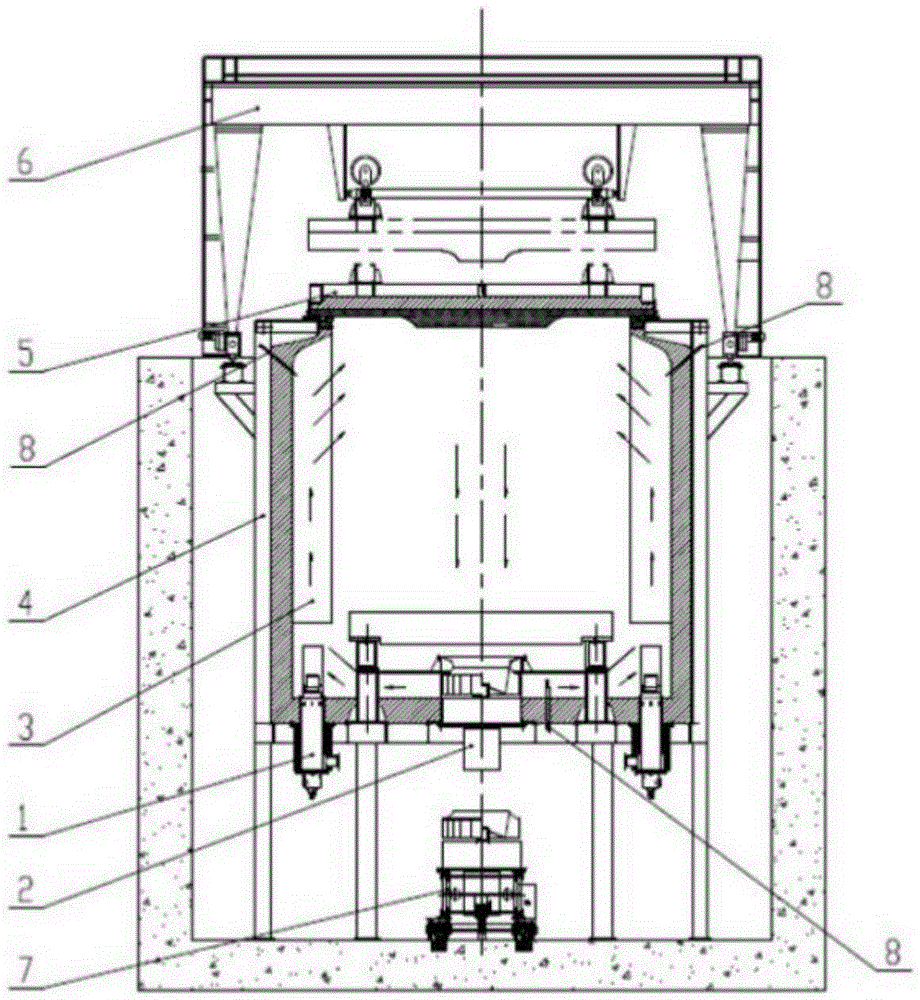

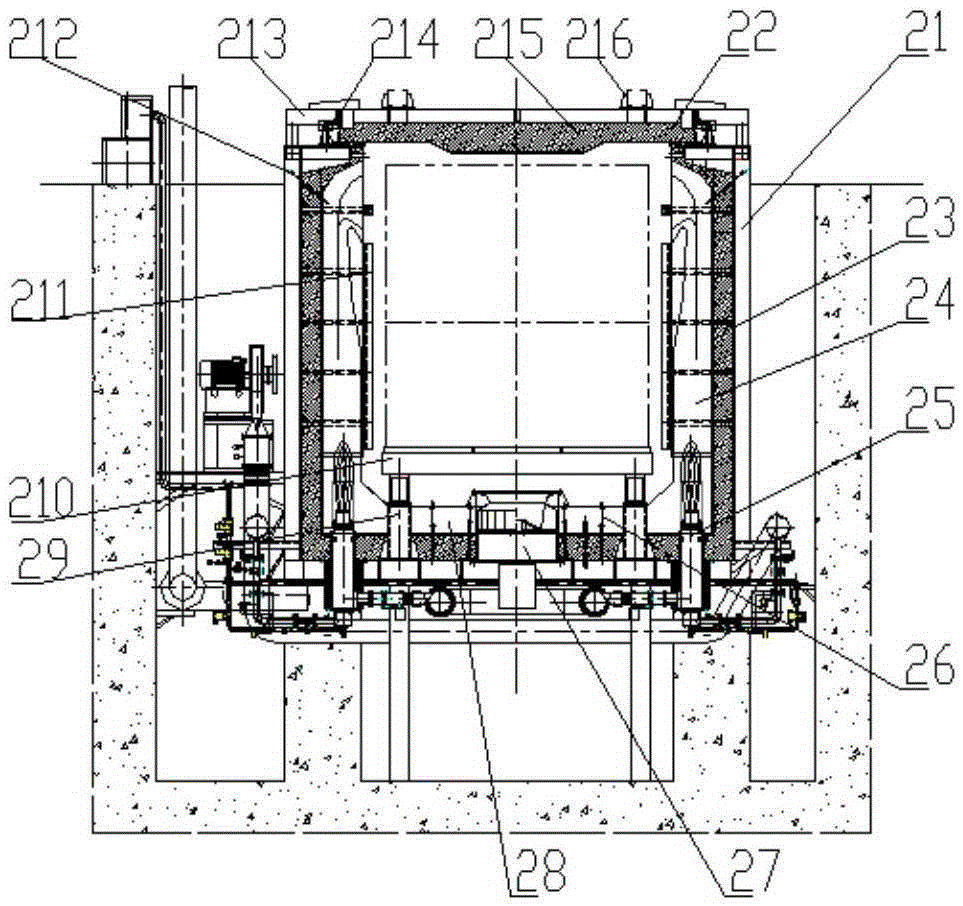

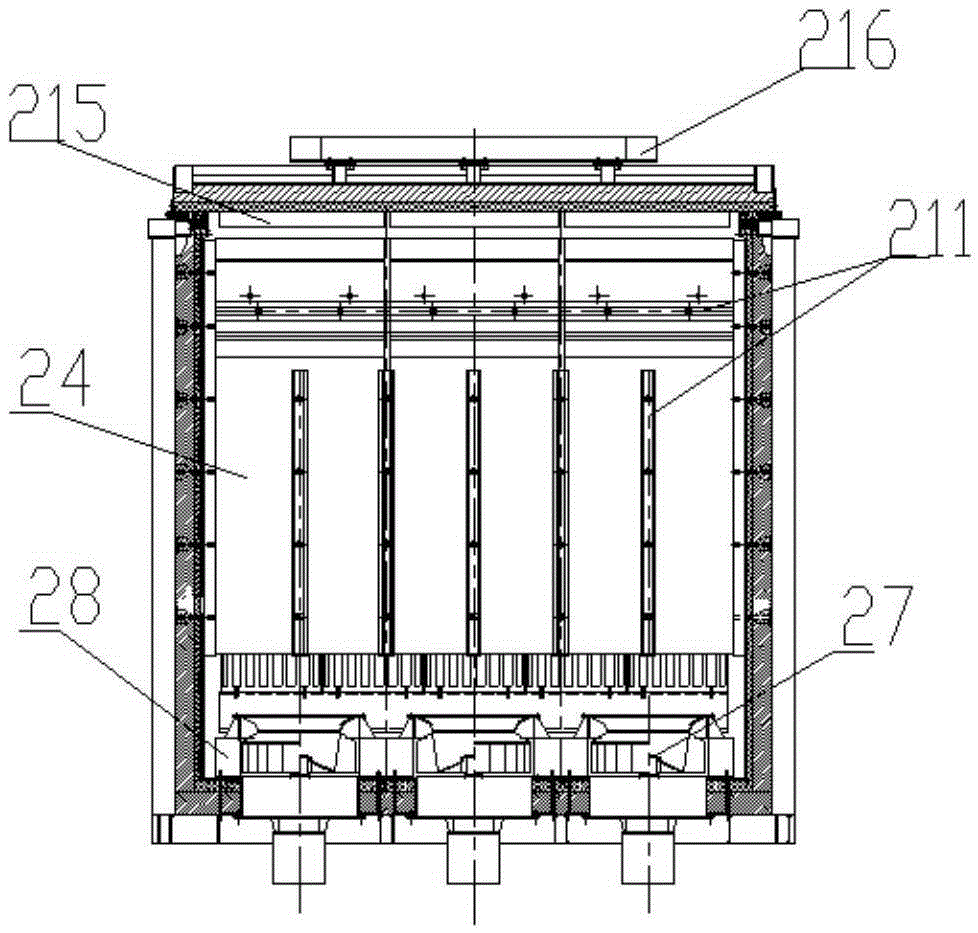

[0031] see figure 2 and image 3 As shown, the pit-type aluminum ingot heating furnace of an embodiment of the present invention includes: a box-type furnace body 21, a furnace cover 22, a flow guide system, a self-preheating burner 25, and a high-temperature centrifugal fan 27. The fan 27 is located at the bottom of the hearth, and the inner surface of the hearth is provided with a heat insulating layer 23. The heat insulating layer 23 in the hearth is welded with the required hanging parts 26 for the flow diversion system in the furnace. The flow diversion system includes a horizontal deflector 28 and a vertical deflector The deflector 24 and the horizontal deflector 28 are located at the bottom of the furnace, distributed on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com