Method for preventing gob-side entry rock burst through side-drawing filling

A technology of rock burst and roadway, which is applied in the field of coal mine prevention and control of rock burst in gob-side roadway by pumping side filling to prevent and control rock burst in gob-side roadway, so as to reduce the trapping of advanced support, eliminate the risk of impact, and reduce the coal pillar The effect of leaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the specific embodiments to further illustrate the technical solution of the present invention.

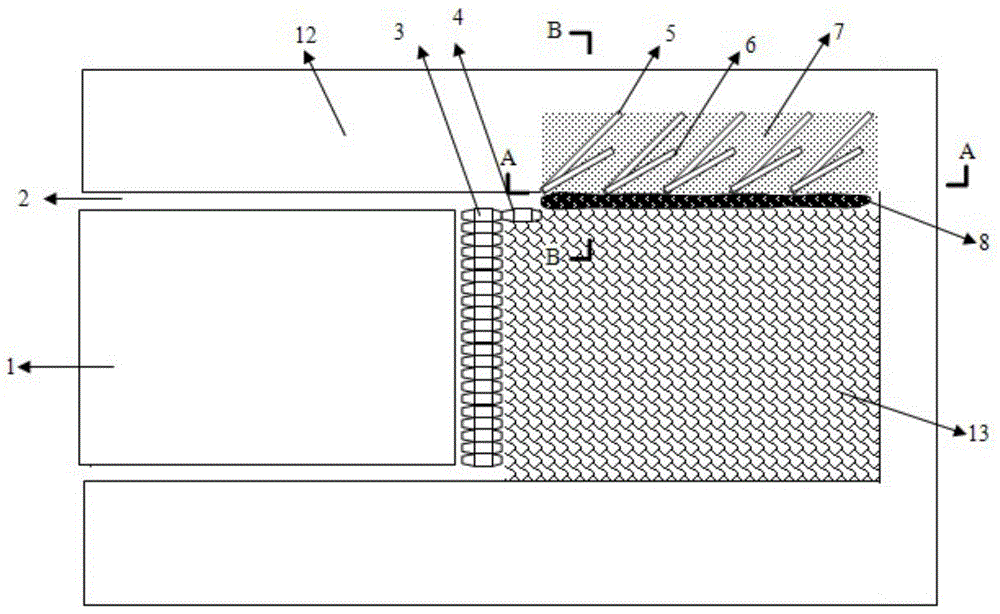

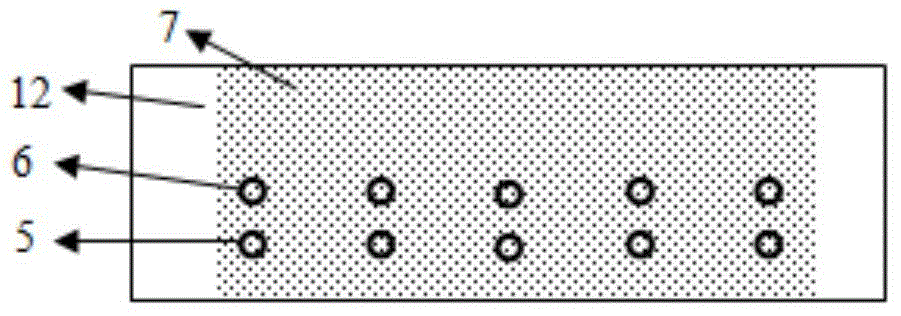

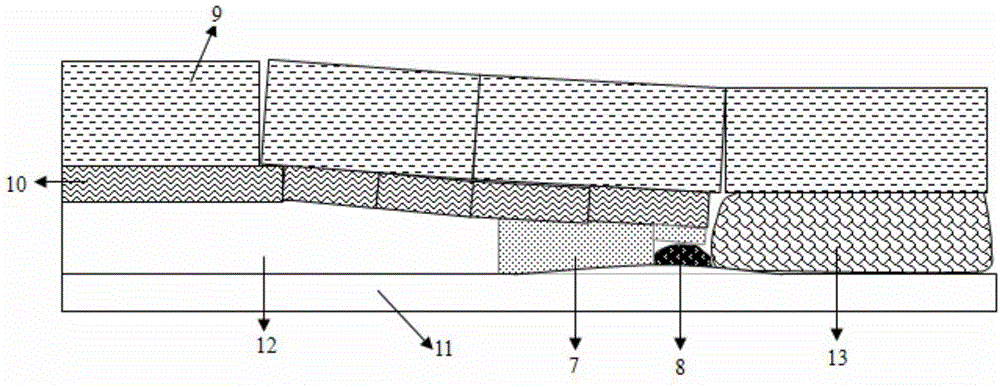

[0019] Such as Figure 1-3 As shown, the present invention utilizes pumping side filling to prevent and control the method for rock burst in gob-side roadway, specifically comprises the following steps:

[0020] 1. In the longwall working face of the deep well, the roadway 2 has a width of 4.5m. First, add a support of the same type behind the mining support 3 of the coal seam working face 1 as support support 4, and ensure that the roadway behind the support is within the range of 210~15m The top plate 10 is complete, and can meet the needs of ventilation, blasting and the like.

[0021] 2. If the average advancing distance of the working face is 5m per day, construct two blasting drill holes in the side of the roadway 2 behind the added support 4, the hole diameter is 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com