Building template system

A construction formwork and formwork technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of cumbersome production and processing of accessories, low universalization of accessories, troublesome disassembly and assembly, etc., to ensure vertical The effect of improving the degree and flatness, preventing safety accidents, and simplifying the production and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

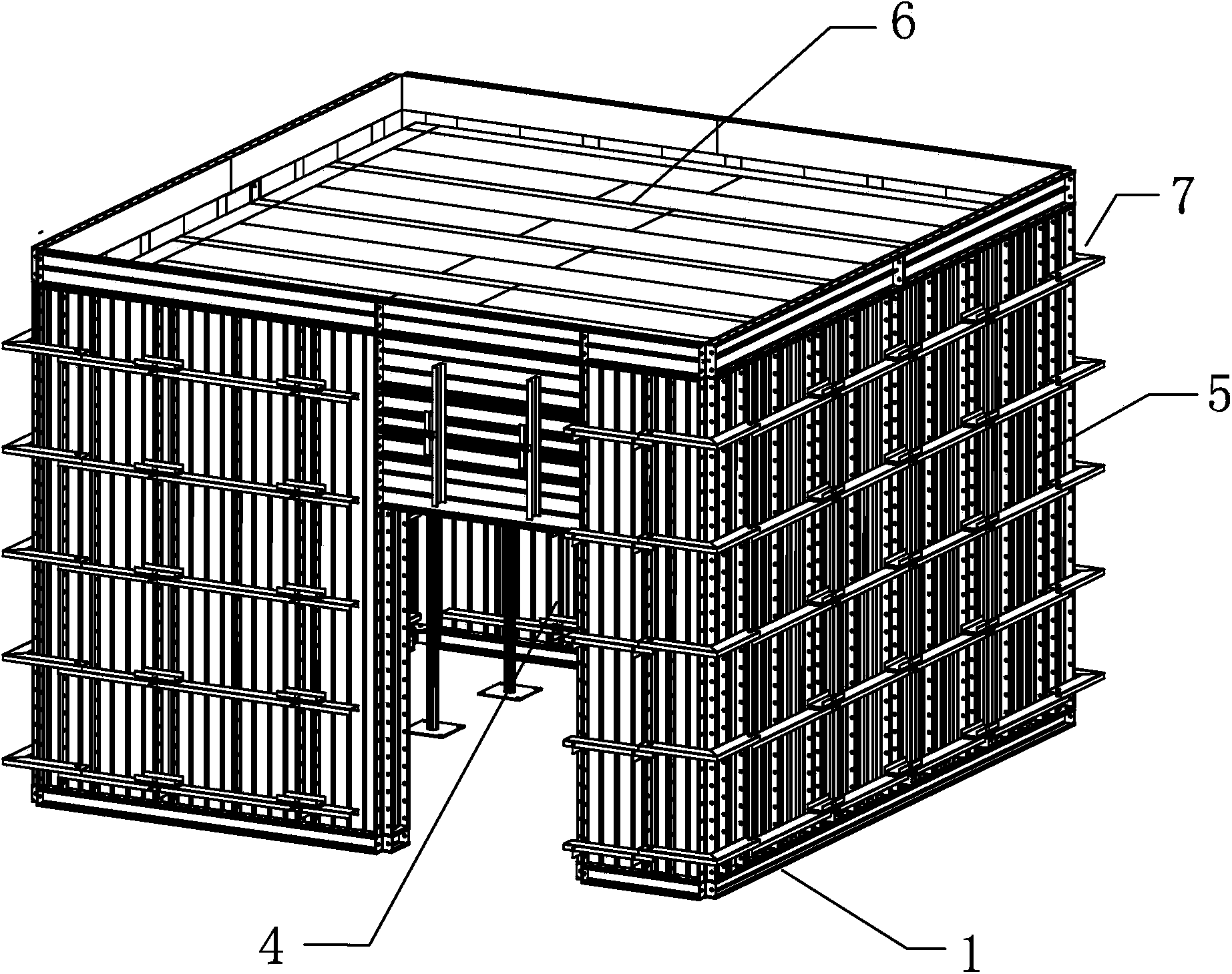

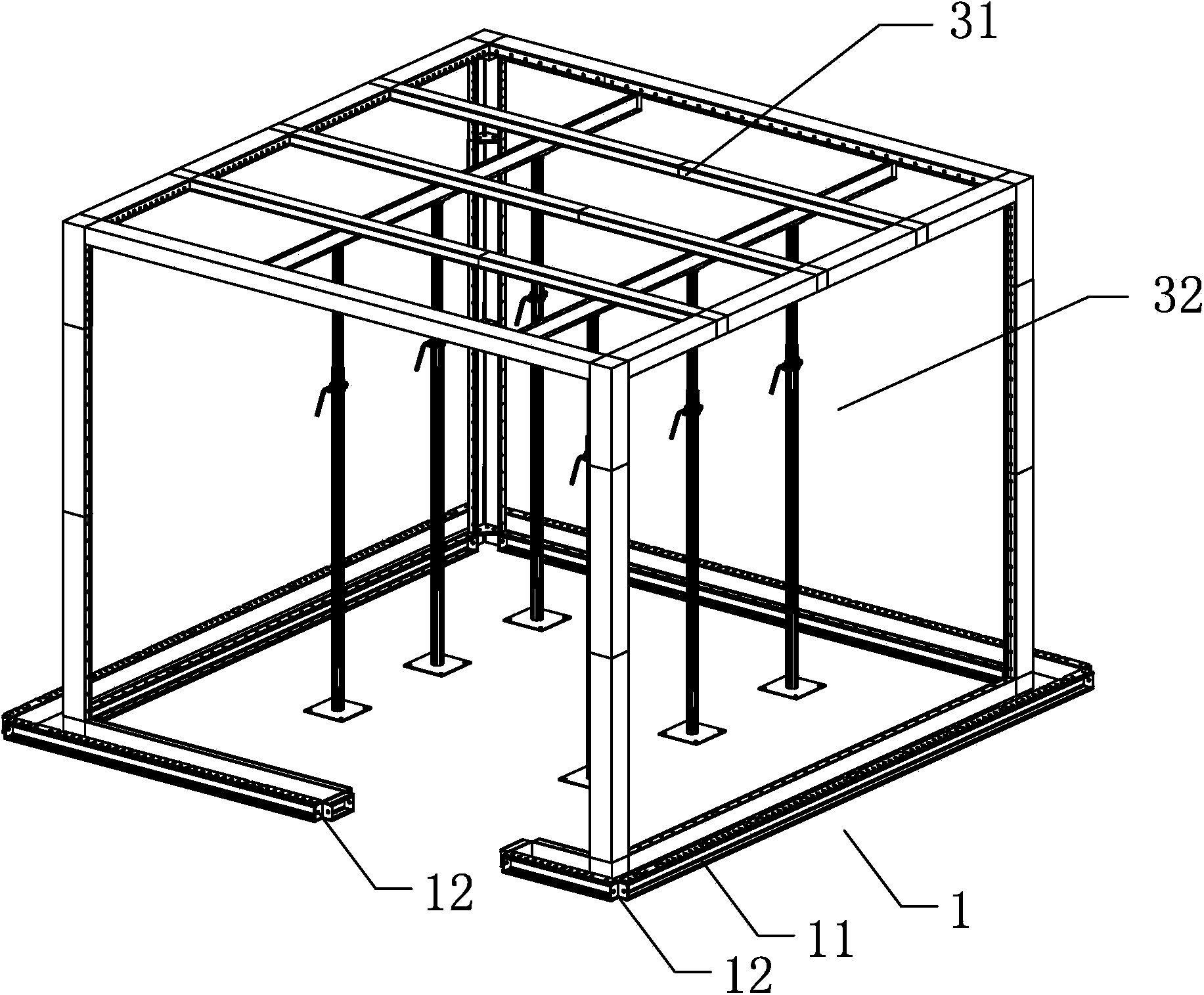

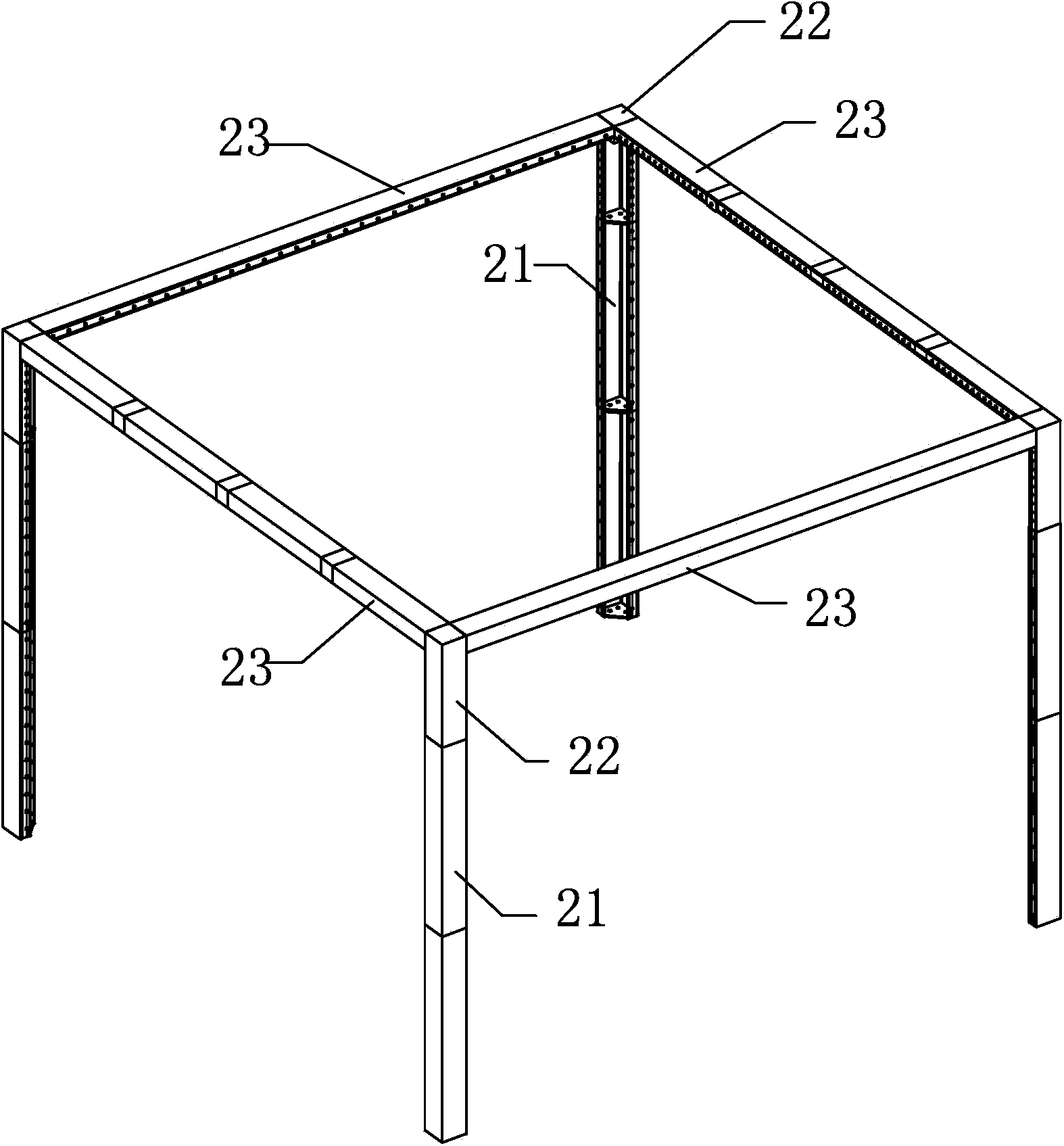

[0030] refer to Figure 1 to Figure 9 , Figure 1 to Figure 9 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, the building formwork system includes: a building formwork system, including a horizontal system 1, a frame system, a keel system, and a panel system. The panel system includes several panel unit panels, A plurality of panel unit boards are spliced on the inner side of the horizontal system 1 and the side of the frame system to form an inner wall panel 4, and a plurality of panel unit boards are spliced on the outer side of the horizontal system 1 to form an outer wall panel 5, and a plurality of panel unit boards are spliced on the A floor panel 6 is formed on the frame system and the keel system, and an exterior wall reinforcement system 7 is arranged between the interior wall panel 4 and the exterior wall panel 5 .

[0031] like Figure 1 to Figure 2 As shown, the horizontal system 1 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com