Closed-cycle circular yellow wine brewing method by squeezing yellow wine lees

A rice wine brewing and closed-loop technology, applied in the preparation of alcoholic beverages, etc., can solve the problems such as the lack of effective development and utilization of nutrients, the failure to maximize the utilization rate of rice wine grains, and the failure to form industrialization. The effect of decreasing the apparent specific gravity, shortening the fermentation period and increasing the degree of gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

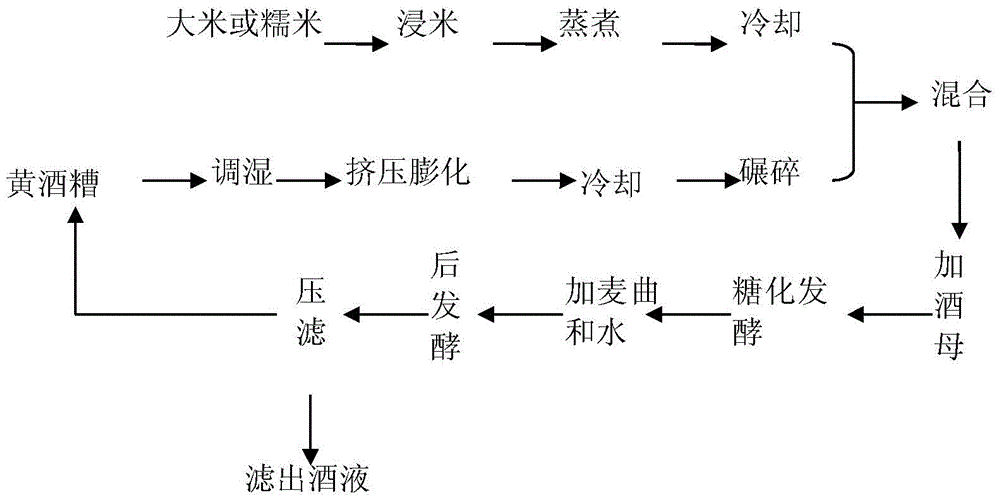

Image

Examples

Embodiment 1

[0019] Embodiment 1 (add enzyme preparation)

[0020] The closed-circuit circulation type rice wine brewing process steps of the present embodiment are as follows:

[0021] (1) Extrusion: Weigh 5kg of wet distiller's grains, adjust the water content of the distiller's grains to 30%, and add high-temperature-resistant protease and high-temperature-resistant α-amylase at the same time, and the addition amount is the high-temperature-resistant protease added per ton of wet-based yellow distiller's grains 0.4kg, adding 0.8kg of high-temperature-resistant α-amylase; using a twin-screw extruder to extrude and expand the yellow rice wine grains added with enzyme preparations, wherein the first section of the sleeve, the second section of the sleeve and the third section of the sleeve The barrel temperature is 40°C, 60°C and 100°C respectively, the screw speed is set at 120rpm, and the extruded rice distiller's grains are cooled for later use.

[0022] (2) Mixed fermentation: Weigh 1...

Embodiment 2

[0026] Embodiment 2 (add enzyme preparation)

[0027] The closed-circuit circulation type rice wine brewing process steps of the present embodiment are as follows:

[0028] (1) Extrusion: Weigh 5kg of wet distiller's grains, adjust the water content of the distiller's grains to 40%, and add high-temperature-resistant protease and high-temperature-resistant α-amylase at the same time, and the amount added is the high-temperature-resistant protease added per ton of wet-based yellow distiller's grains 0.4kg, adding 0.8kg of high-temperature-resistant α-amylase; using a twin-screw extruder to extrude and expand the yellow rice wine grains added with enzyme preparations, wherein the first section of the sleeve, the second section of the sleeve and the third section of the sleeve The barrel temperature is 60°C, 80°C and 100°C respectively, the screw speed is set at 120rpm, and the extruded yellow rice distiller's grains are cooled for later use.

[0029] (2) Mixed fermentation: Wei...

Embodiment 3

[0033] Embodiment 3 (do not add enzyme preparation)

[0034] The closed-circuit circulation type rice wine brewing process steps of the present embodiment are as follows:

[0035] (1) Extrusion and puffing: Weigh 5kg of wet distiller's grains, adjust the water content of the distiller's grains to 30%, and use a twin-screw extruder to extrude and puff the distiller's grains. The first section of the sleeve, the second section of the sleeve The temperatures of the sleeve and the third section are respectively 60°C, 80°C and 140°C, the screw speed is set at 100rpm, and the extruded yellow rice wine lees are cooled for later use.

[0036] (2) Mixed fermentation: Weigh 10kg of rice wine brewing raw material (glutinous rice), cook and pre-treat it according to the traditional process, mix it with the rice wine lees processed in step (1) at a mass ratio of 2:1 after cooling, and add distiller's mother Then carry out saccharification and fermentation, and the conditions such as ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com