Oil-based mud flushing fluid suitable for high temperature high salt environment and preparation method of oil-based mud flushing fluid

A technology of oil-based mud, high temperature and high salt, applied in the field of mud flushing fluid, to achieve the effect of simple preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In 100 parts by weight, weigh the following components respectively: 55 parts of clear water, inorganic salt CaCl 2 40 parts, 2.5 parts of ionic surfactant AES, 2.5 parts of nonionic surfactant (a mixture of C12EO4 and C12EO23 in a weight ratio of 1:1). Mix the above-mentioned components, heat to 80°C under stirring, make the mixture uniform, and then cool naturally to room temperature to obtain the oil-based mud flushing fluid.

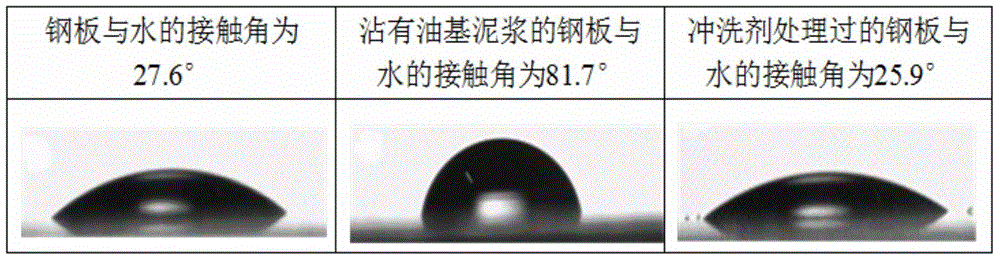

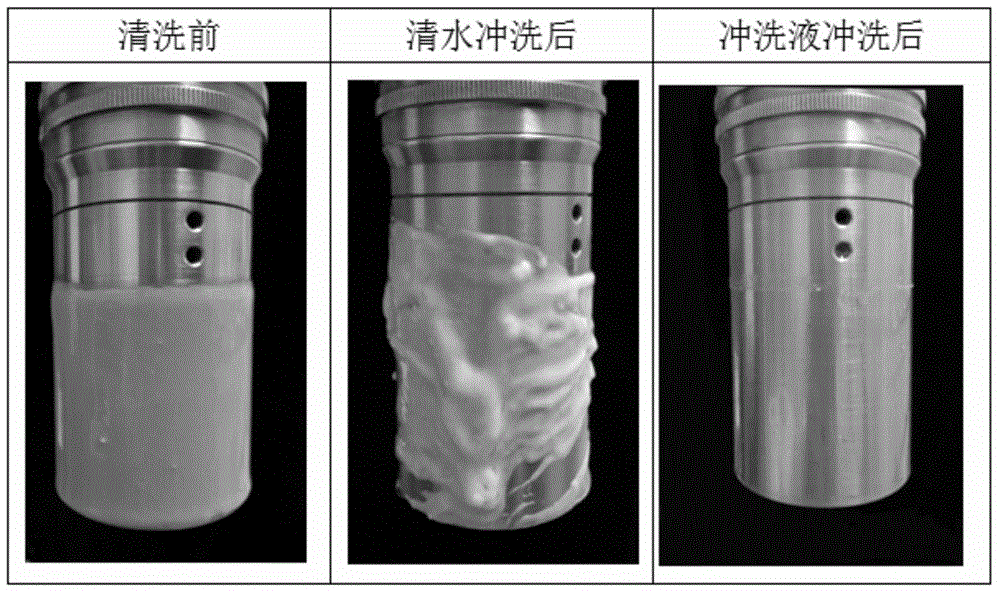

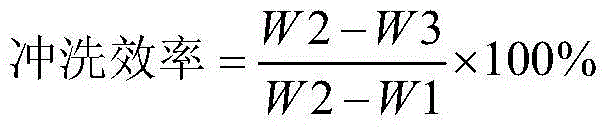

[0032] Investigate the flushing effect of the prepared oil-based mud flushing fluid: (1) Immerse the inner cylinder of the six-speed rotary viscometer in water for 30 minutes, take it out and dry it at room temperature (25°C) for 40 minutes, and weigh W1; (2) The six-speed rotary viscometer Soak the inner cylinder of the rotary viscometer in oil-based drilling fluid for 30 minutes, take it out and dry it at room temperature for 40 minutes, and weigh W2; Put it into the sample cup of the rotational viscometer, start the rotational viscometer a...

Embodiment 2

[0038] In 100 parts by weight, weigh the following components respectively: 53 parts of clear water, inorganic salt CaCl 2 40 parts, 3.5 parts of ionic surfactant AES, 3.5 parts of nonionic surfactant (a mixture of C12EO4 and C12EO23 in a weight ratio of 1:1). The above-mentioned components are mixed, heated to 80°C under stirring, mixed evenly, and then naturally cooled to room temperature to obtain an oil-based mud flushing fluid. According to the method of Example 1, the flushing efficiency of the oil-based mud flushing fluid and the contact angle after flushing were investigated. Data are as follows:

[0039] rinse temperature

Embodiment 3

[0041] In 100 parts by weight, weigh the following components respectively: 60 parts of clear water, inorganic salt CaCl 235 parts, 2.5 parts of ionic surfactant AES, 2.5 parts of nonionic surfactant (a mixture of C12EO4 and C12EO23 in a weight ratio of 2:3). The above-mentioned components are mixed, heated to 80°C under stirring, mixed evenly, and then naturally cooled to room temperature to obtain an oil-based mud flushing fluid. According to the method of Example 1, the flushing efficiency of the oil-based mud flushing fluid and the contact angle after flushing were investigated. Data are as follows:

[0042] rinse temperature

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com