A kind of vacuum defoaming method for improving the clarification quality of molten glass liquid

A technology for melting glass and defoaming, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as pollution, increase production cost, and have not yet found technical solutions, and achieve the effect of improving the quality of clarification and improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

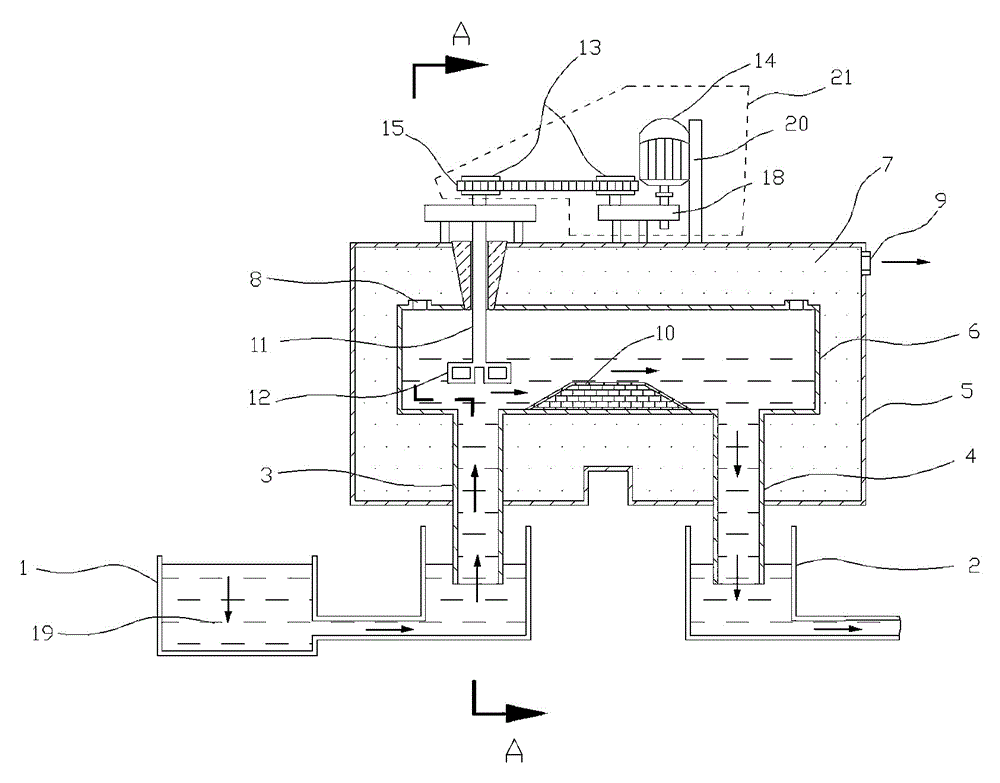

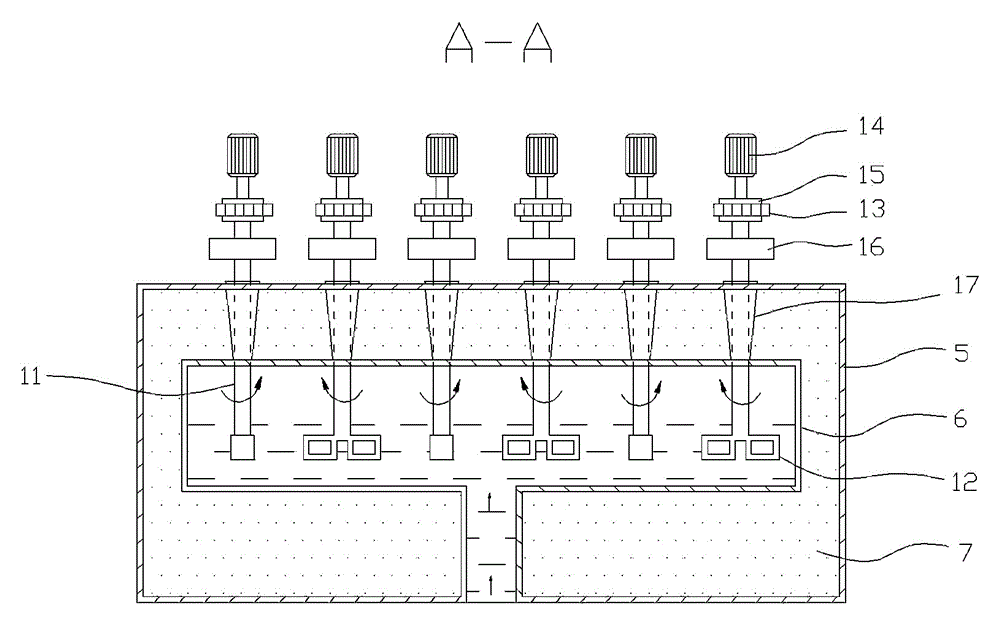

[0022] Such as figure 1 with figure 2 As shown, a kind of degassing degassing method for improving the clarification quality of molten glass provided by the present invention comprises a decompression shell 5, a degassing degassing tank 6 is provided in the decompression shell 5, and the top of the degassing degassing tank 6 An exhaust port 8 is respectively arranged on both sides, and the exhaust port 8 communicates with the exhaust port 9 of the decompression shell 5, and the inside of the decompression degassing tank is decompressed by an external vacuum pump, and the decompression shell 5 is connected with the decompression degassing tank. The heat insulating material 7 is provided between the bubble tanks 6, the introduction end of the decompression degassing tank 6 is provided with the riser pipe 3 that introduces the molten glass liquid 19, and the outlet end is provided with the downcomer 4 that leads the molten glass liquid 19, and the introduction end is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com