Remote tower crane monitoring circuit with self-diagnostic function

A technology for tower cranes and remote monitoring, applied to cranes, etc., can solve problems such as inconvenient management, inability to manage in a unified manner, and poor real-time performance, and achieve unified monitoring and management, cross-regional transmission, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

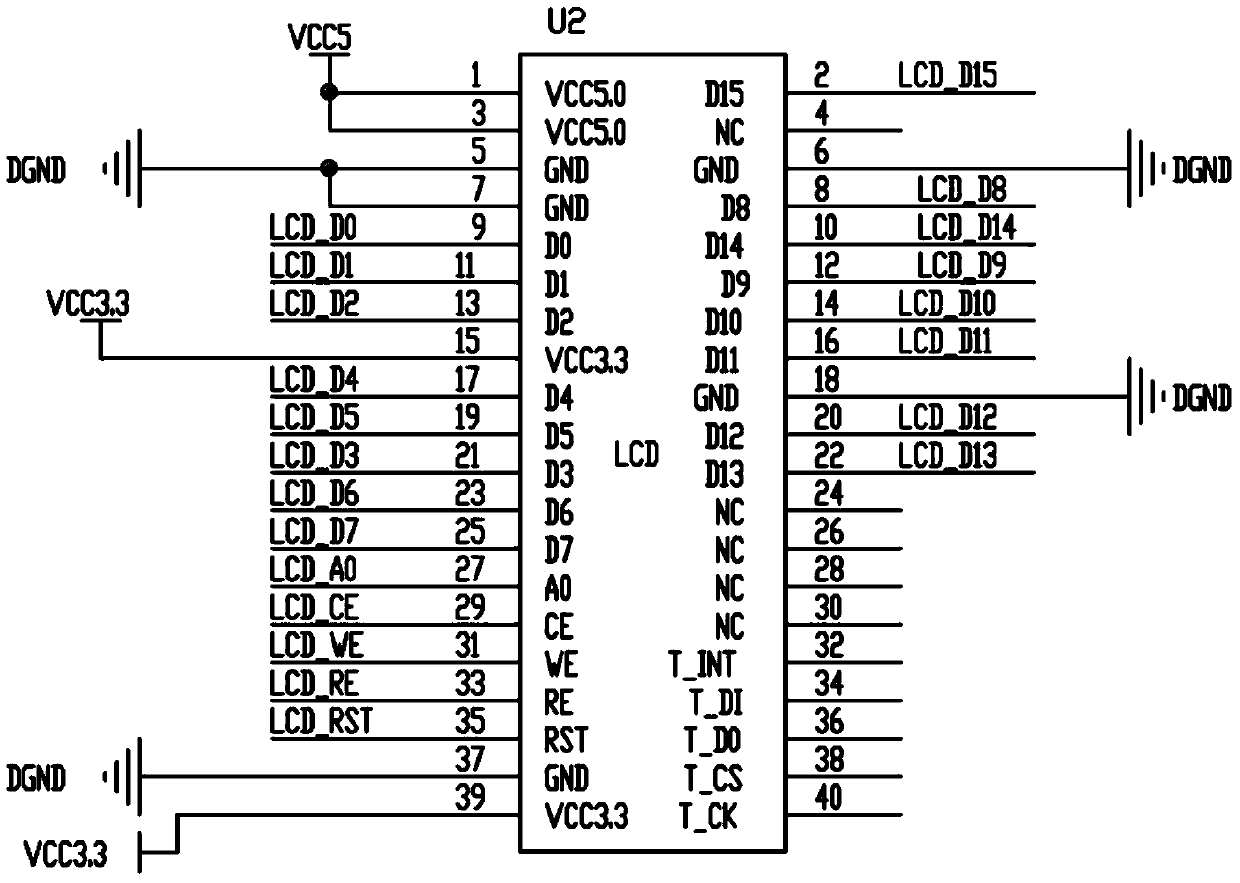

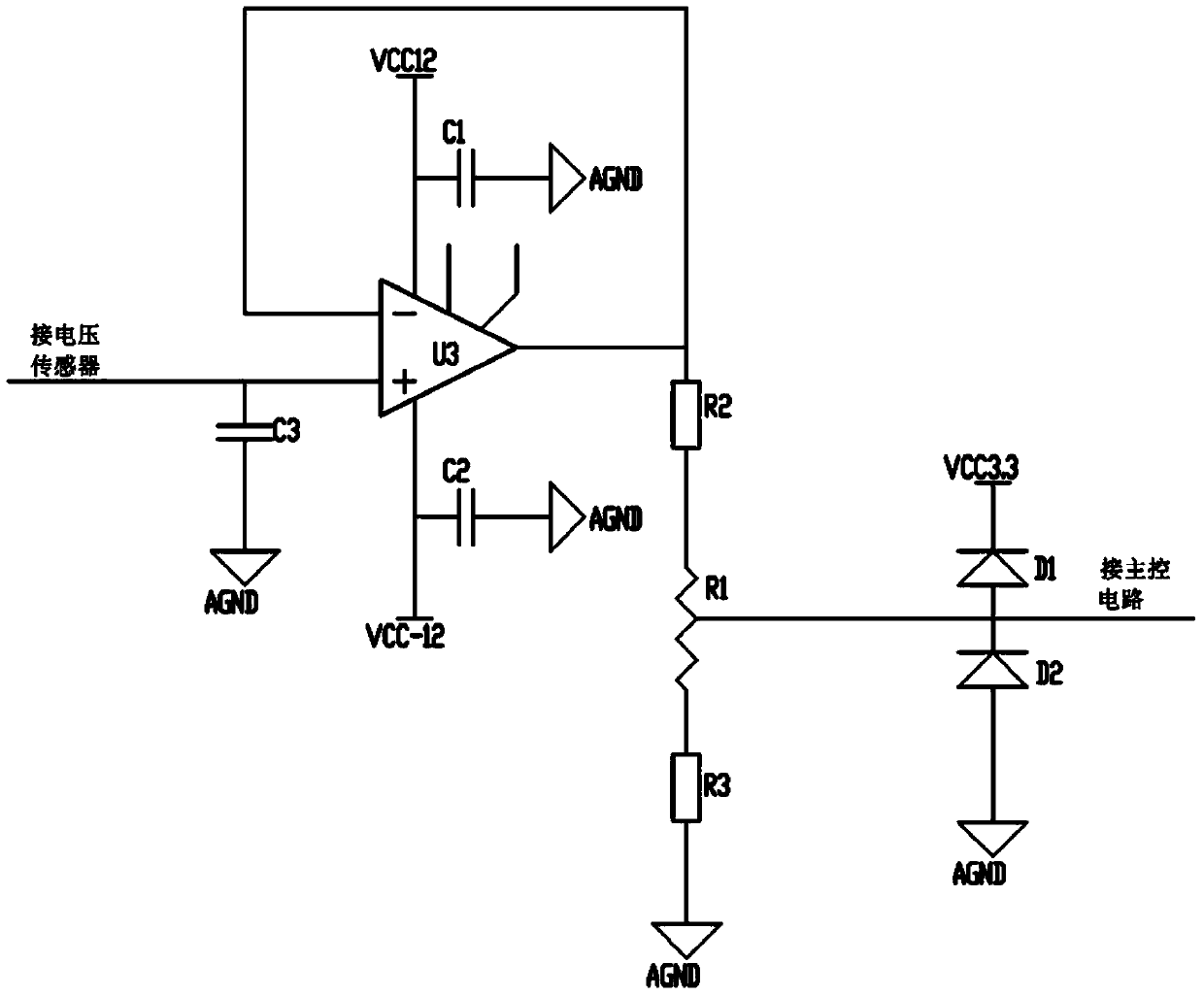

[0035] See attached figure 1 ~ attached Figure 8, a tower crane remote monitoring circuit with self-diagnosis function, which includes a plurality of sensors, a sampling circuit, a main control circuit, a display circuit, an alarm circuit, a relay drive circuit and a GPRS wireless communication module; the main control circuit includes a central processing unit and a self-diagnosis circuit; each sensor in the plurality of sensors is connected to the sampling circuit, and the sampling circuit and the display circuit are connected to the central processing unit of the main control circuit; the alarm circuit and The GPRS wireless communication modules are all connected with the self-diagnosis circuit of the self-diagnosis circuit of the main control circuit; .

[0036] Such as figure 1 , the sensor group composed of load cell, slewing sensor, amplitude sensor, height sensor, wind speed sensor, voltage sensor, current sensor and temperature sensor collects the operating para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com