Vehicle-mounted insulation ladder device

An insulating ladder, vehicle-mounted technology, applied in the layout of pedals or ladders, ladders, vehicle parts, etc., can solve the problems of insufficient power maintenance, difficulty in protection, and inability to completely avoid friction between insulating ladders and brackets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

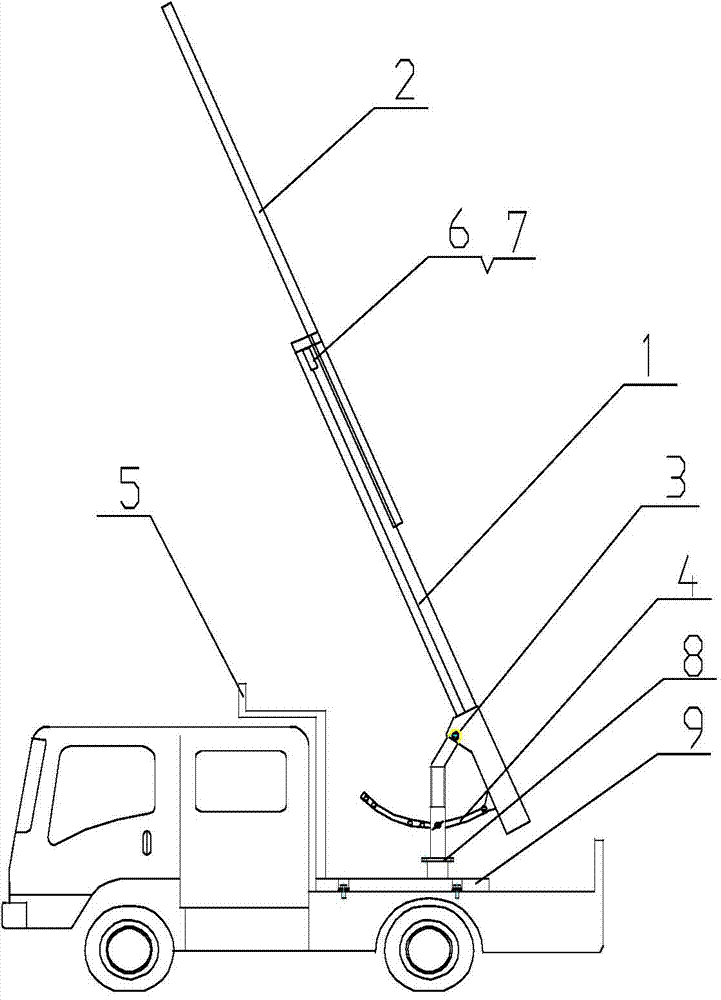

[0026] Embodiment 1, a vehicle-mounted insulation ladder device, refer to figure 1 , figure 2 : The vehicle-mounted insulating ladder device is mainly composed of insulating ladder fixing section 1, insulating ladder telescopic section 2, pitching mechanism 3, elevation angle positioning locking mechanism 4, insulating ladder bracket and locking mechanism 5, pulley mechanism 6, ratchet mechanism 7, rotary Main structures such as a tower frame 8 and a frame-type underframe 9 are formed.

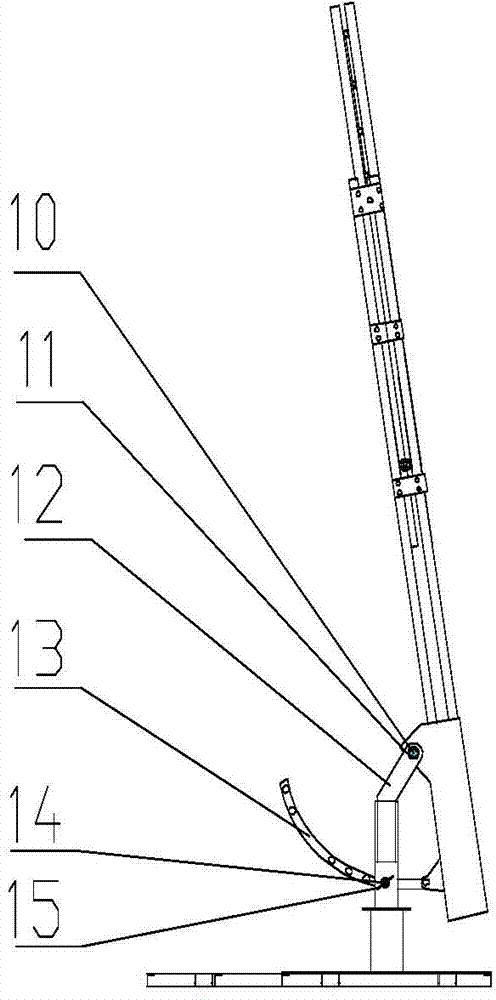

[0027] refer to image 3 : The pitching mechanism 3 is composed of a pitching hinge sleeve 10 and a pitching hinge shaft 11, the pitching hinge sleeve 10 is fixedly connected with the middle and lower part of the insulating ladder fixed section 1, the pitching hinge shaft 11 is fixedly connected with the slewing tower 12, and the pitching hinge sleeve 10 is connected with the pitching hinge After the shaft 11 is threaded and fitted, it serves as the rotation fulcrum for the pitching motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com