A fixture box on a drill pipe joint

A drill pipe joint and fixture box technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of low work efficiency and unstable shackle torque, and achieve the effects of high work efficiency, simple action and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

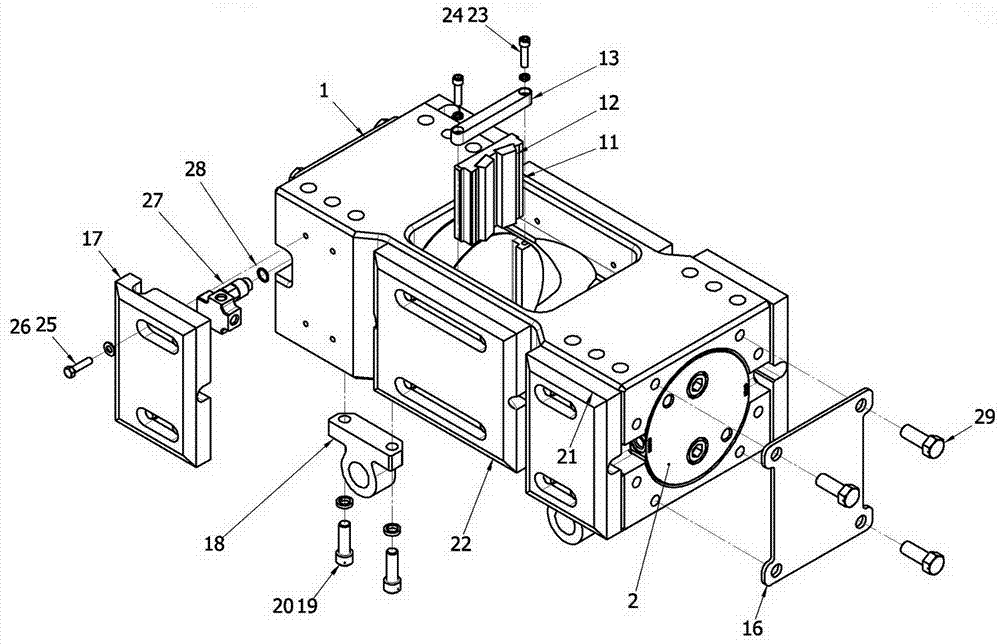

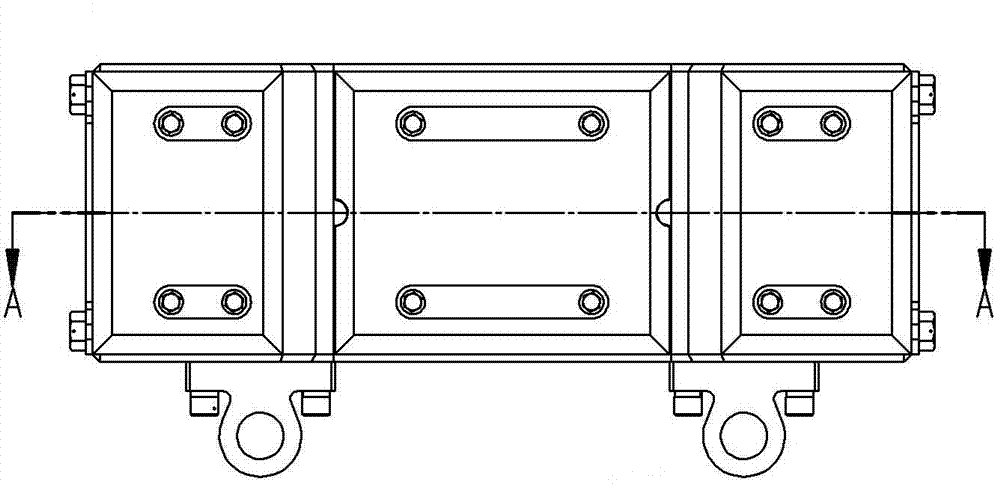

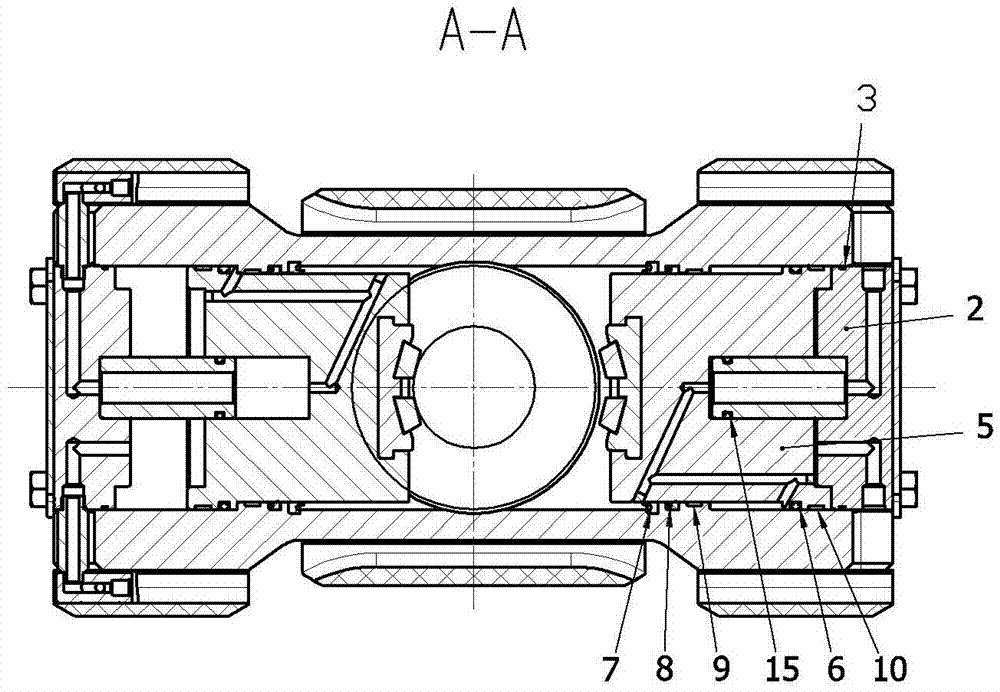

[0020] Such as figure 1 As shown, the present invention provides a clamp box on a drill pipe joint, which is characterized in that the clamp box is mainly composed of a housing 1, a positioning box 4 located at one end of the housing and a locking box located at the other end of the housing , there is a certain piston 5 in the positioning box 4, a locking piston in the locking box, pliers are installed on the ends of the fixed piston 5 and the locking piston, and buffering is installed on both sides of the housing 1. device; the pliers are composed of die fixing plate 11, pliers die insert 12 and pliers baffle bar 13, the die fixing plate 11 is fixed on the fixed piston 5 and the end of the locking piston, the The pliers die insert 12 is fixed on the die fixing plate 11, and the pliers baffle strip 13 is fixed on the end of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com