Production process of rolling product

A production process and product technology, which is applied in the production process of rolling products, can solve the problems of high material consumption and complex processing technology, and achieve the effects of high production efficiency, smooth production process, and reduced transfer links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

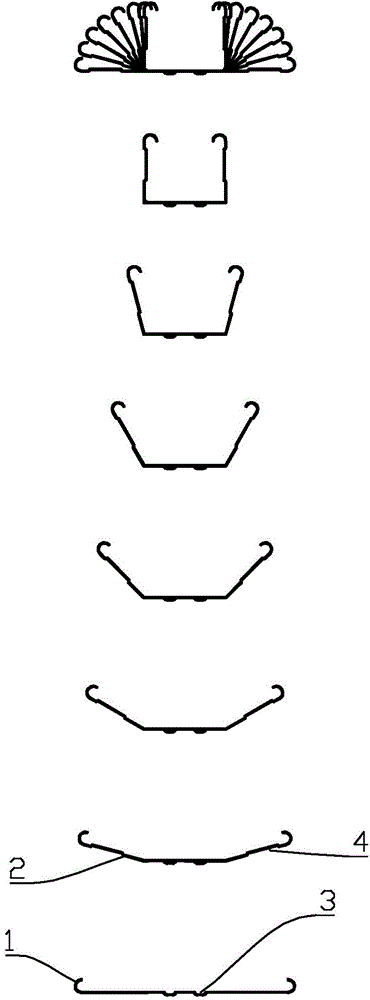

[0045] refer to Figure 1 to Figure 13 , the present invention is a kind of production technology of rolling product, comprises the following steps:

[0046] 1. Prepare raw materials: metal plates, stainless steel plates or alloy plates and other metal plates can be used;

[0047] 2. Punch holes at the set position of the metal sheet through the punching device on the rolling machine (for assembly);

[0048] 3. Use the rolling machine to roll out the first groove 3 in the middle of the metal sheet, which is used to strengthen the structural strength of the metal sheet; 4. Use the rolling machine to fold the sides of the metal sheet to form a The main body of the sheet is folded at 90° 1;

[0049] 5. Hemming 1 is carried out by rolling machine;

[0050] 6. Folding the sheet metal with a rolling machine, forming a side 2 at a 90° angle to the main body of the sheet metal on both sides, and forming a second groove 4 on the side 2 to strengthen the structural strength of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com