A device and method for continuous rapid reaction crystallization to improve crystal stability

A fast reaction and stable technology, applied in solution crystallization, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, etc. and other problems, to achieve the effect of good purity and stability, saving resources and labor, and reducing consumption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

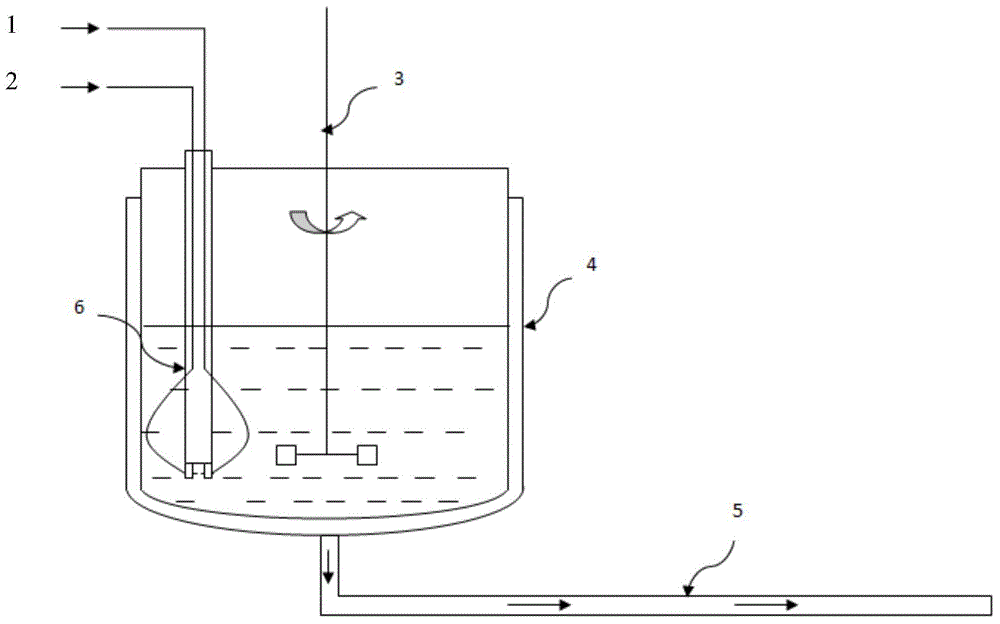

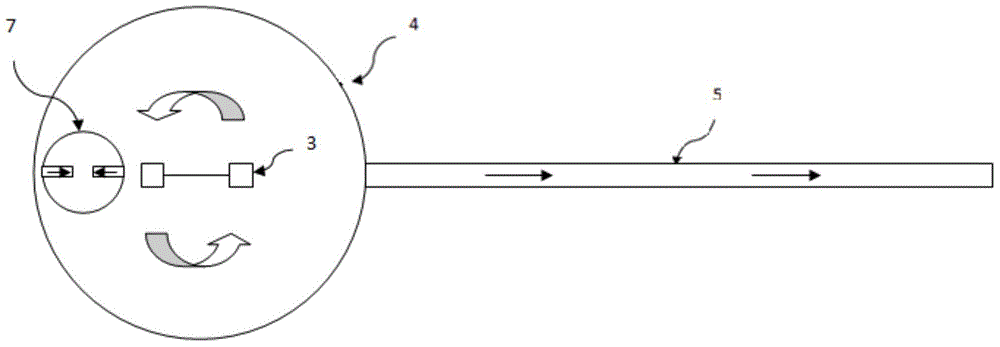

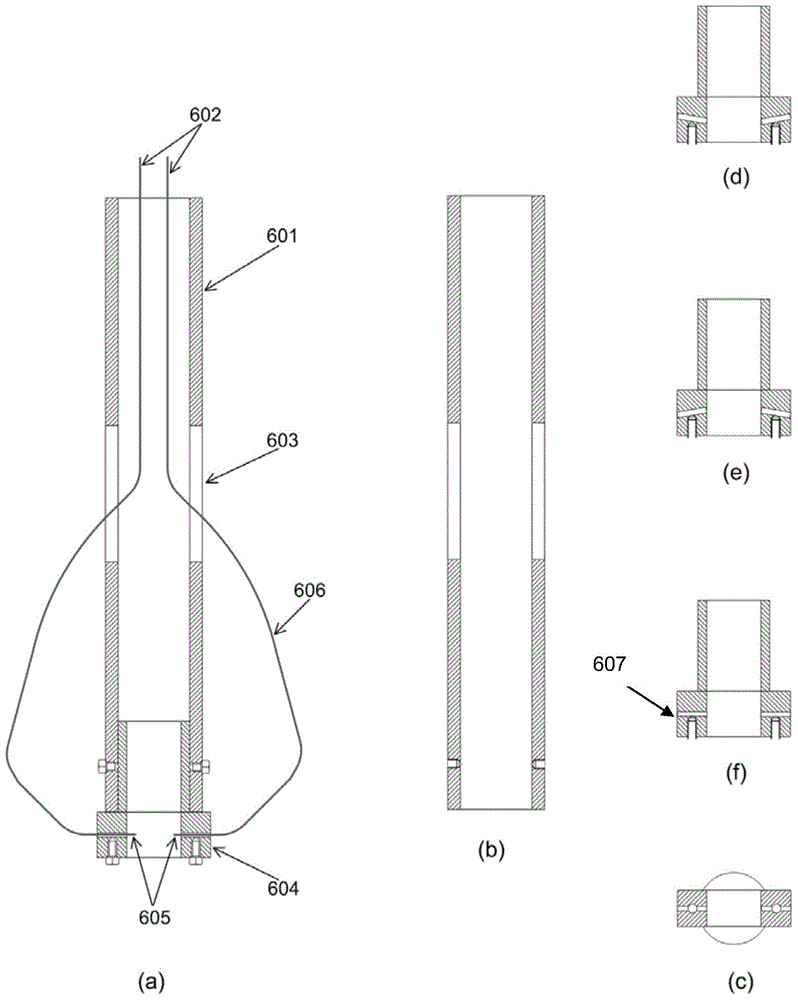

[0044] A device for continuous rapid reaction crystallization to improve crystal stability, such as figure 1 , 2 , 3, including a tank reactor 4 and a tubular reactor 5 connected in series; a liquid jet impact feed device 6 is set in the tank reactor 4, and the liquid jet impact feed device 6 includes a vertical Straight hollow tube 601 and two feeding tubes 602, the tube wall of hollow tube 601 is provided with through hole 603 for feeding tube to pass, and described feeding tube 602 is inserted from the upper port of hollow tube 601, and from The through hole 603 on the pipe wall passes through, and the discharge port of the feeding pipe 602 is connected with a nozzle 605, and the nozzle 605 of each feeding pipe is fixed by a fixing frame 604, and the fixing frame is uniformly arranged along the circumference of the pipe. There are two clamping holes 607 for fixing the nozzle; the feeding pipe section between the through hole 603 on the hollow pipe and the fixing frame 604 ...

Embodiment 2

[0054] The difference between the continuous rapid reaction crystallization of the present implementation and the device for improving crystal stability is that the liquid jet impacts the feeding device, wherein the angle formed between the nozzle and the horizontal plane is 10°, and the distance is 12mm, such as image 3 (d) shown.

[0055] Production process of continuous rapid reaction crystallization of cefuroxime sodium in a pilot-scale reactor

[0056] Dissolve 720g of sodium lactate (60%) in a mixed solvent of 3200ml of acetone and 4000ml of ethanol (95%) at 20-25°C. After stirring for 20 minutes, the mixture was filtered, washed with 1000 ml of ethanol (95%), and put into a beaker together with the filtrate (the first feed liquid 1). Dissolve 800g of cefuroxime acid in a mixed solvent of 2000ml of acetone and 1000ml of ethanol (95%), add 100g of activated carbon and stir at 38-42°C for 20-30 minutes to decolorize. Then, the mixture was filtered, and the activated car...

Embodiment 3

[0063] The continuous rapid reaction crystallization of this implementation improves the device of crystal stability and the difference of embodiment 1 is:

[0064] The angle between the nozzle and the horizontal plane is 15°, and the spacing is 10mm, such as image 3 (e) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com