Novel interlayer pot and using method thereof

A sandwich pot, a new type of technology, applied in the fields of boiling and separating sandwich pots, and stirring, can solve the problems of easy burns for workers, increased work difficulty, and low work efficiency, so as to improve work efficiency and operation safety index, and improve raw materials Utilization rate, eliminating the effect of manual scooping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

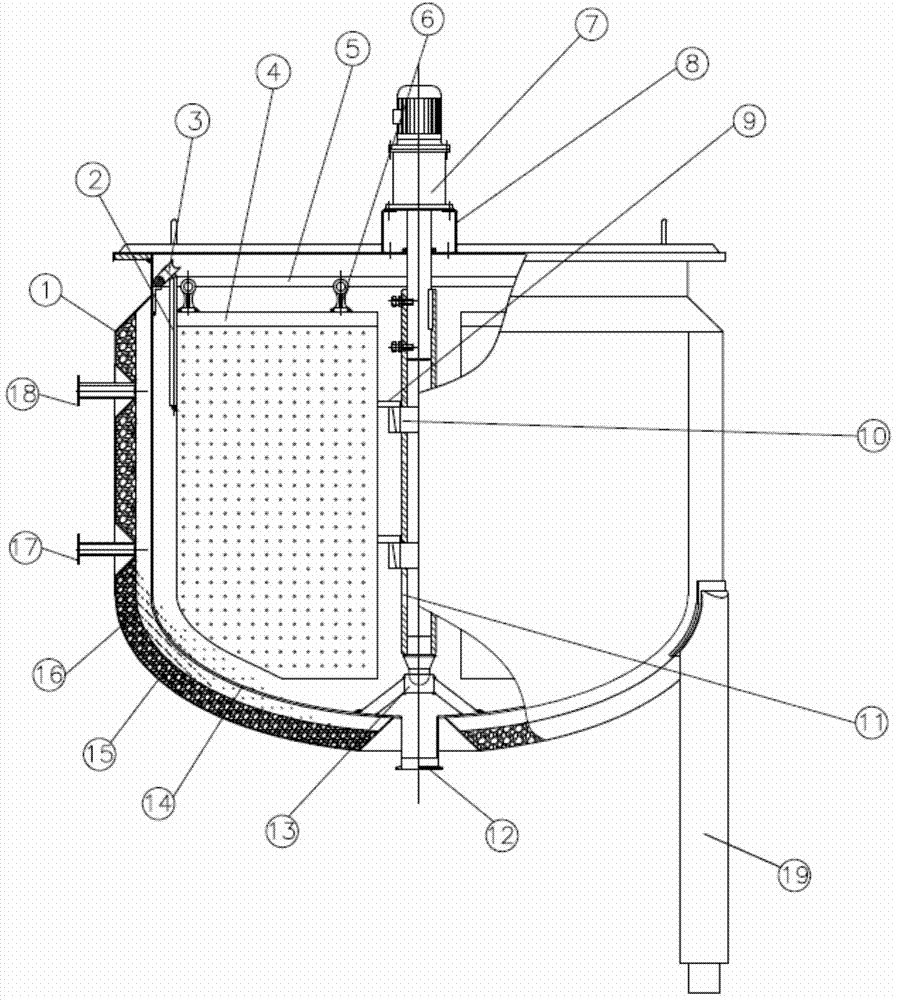

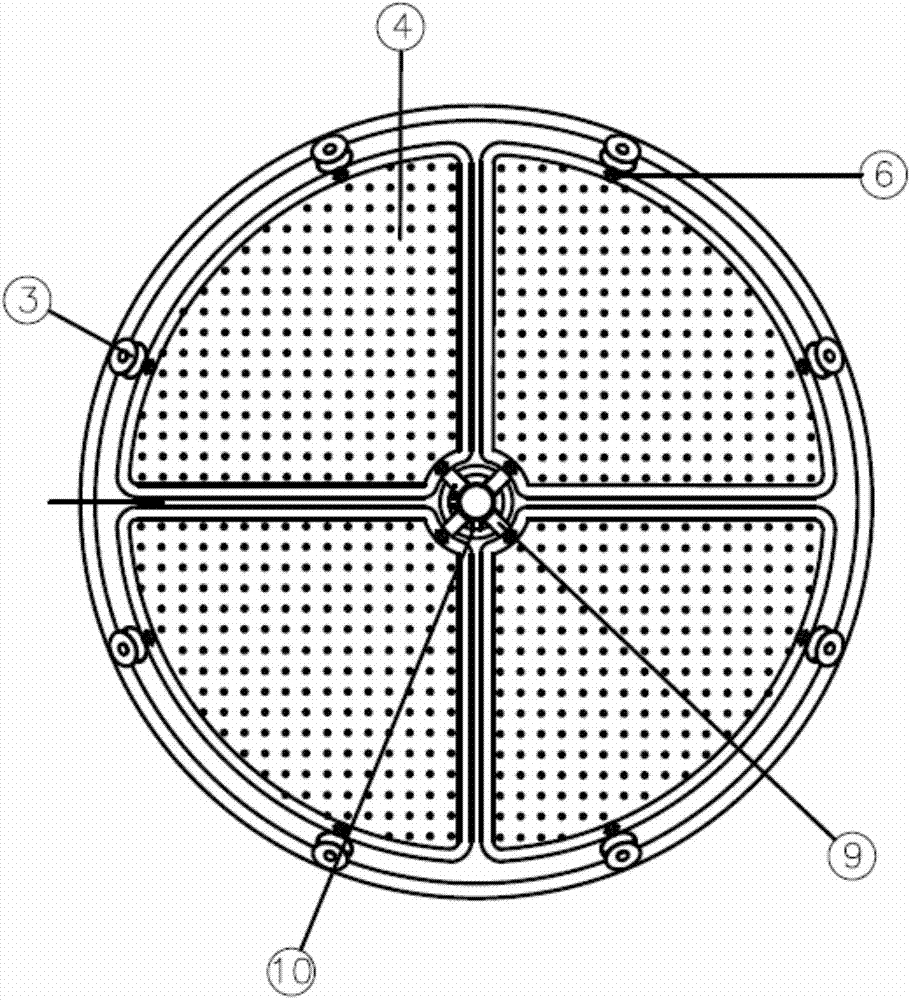

[0025] Such as figure 1 The shown jacketed pot includes a pot body 1 and three legs 19. The pot body 1 includes an insulating layer 15, a jacket outer wall 16, and a jacket inner wall 14 from outside to inside. A steam inlet 18 is provided at the upper end of one side of the jacket outer wall 16, a condensed water outlet 17 is provided at the lower end of the same side, and a liquid material outlet 12 is provided at the center of the bottom. The bottom end of the stirring shaft 11 is connected to the support 13 , the top end of the stirring shaft 11 is connected to the power unit 7 , and the power support 8 connected to the power unit 7 is fixedly connected to the upper end of the pot body 1 . The inside of the pot body 1 is provided with a fan-shaped inner container 4, which is used to hold solid materials that need to be boiled, and a large number of small holes are arranged on the inner container 4 wall. The side of the liner 4 in contact with the stirring shaft 11 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com