Oil capable of gradually updating used food fryers

A food and frying machine technology, applied in the direction of oil/fat baking, etc., can solve the problems of high energy consumption, achieve the effects of improving health, saving labor costs, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

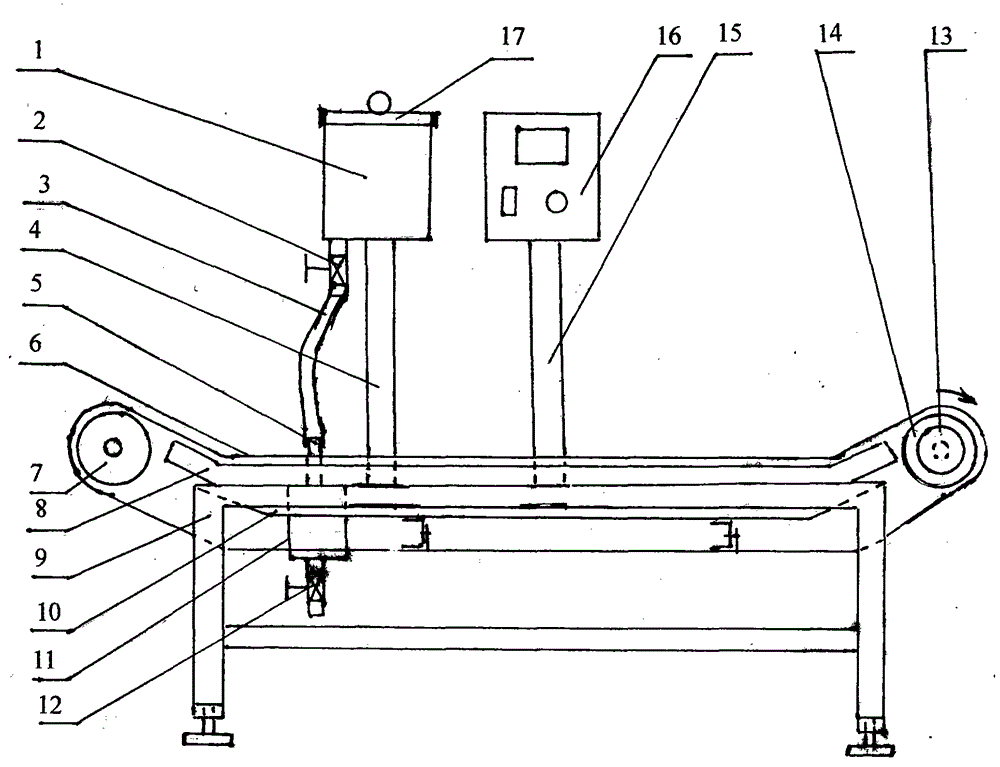

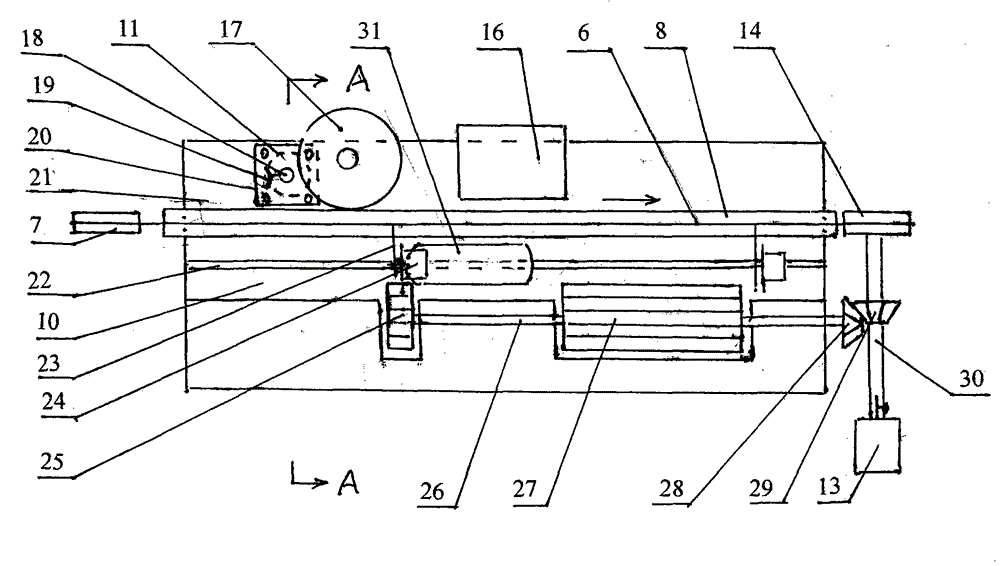

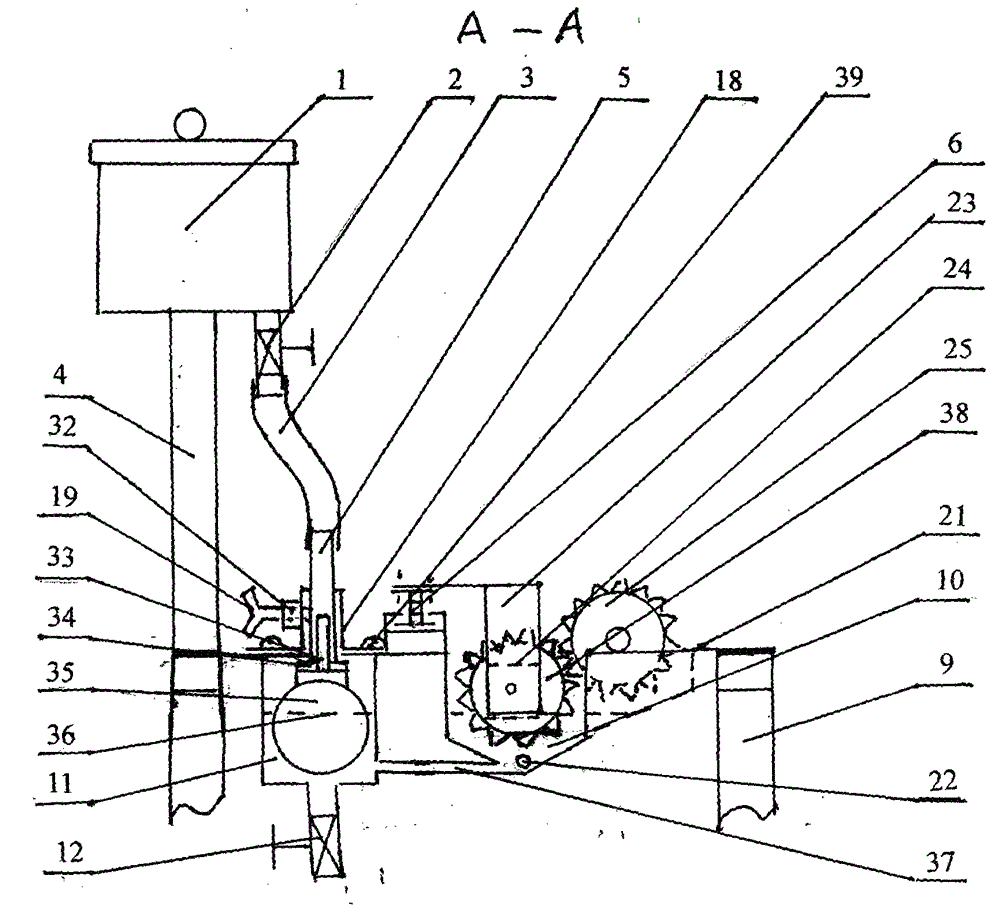

[0006] Specific implementation mode one: (see Figure 1 ~ Figure 3 ) This embodiment consists of a fuel tank 1, a fuel tank valve 2, an oil-resistant hose 3, a fuel tank pole 4, an oil level regulating pipe 5, a four-bend chain 6, a driven sprocket 7, a chain track 8, a frame 9, an oil tank 10, a float Chamber 11, oil discharge valve 12, motor 13, drive sprocket 14, control instrument box strut 15, control instrument box 16, fuel tank cover 17, fixed pipe 18, fastening screw 19, float chamber cover 20, platform 21, Electric heating tube 22, toggle plate 23, flipping device 24, one-time turning tooth wheel drum 25, wheel drum shaft 26, multiple turning tooth wheel drum 27, wheel drum shaft bevel gear 28, driving shaft bevel gear 29, Drive shaft 30, flat-column fried object 31, fastening nut 32, guide post device 33, oil-resistant rubber ring 34, float 35, oil surface 36, connecting oil pipe 37, gear piece 38, screw 39, casing foot 40 , insulation layer 41, control meter box po...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see Figure 1 to Figure 6 ) The food frying machine in this embodiment whose oil can be gradually updated is a table-top structure, and the top of the front part of the casing 43 is provided with a control instrument box pole jack 42 and a fuel tank pole jack 44, and the lower end of the fuel tank pole 4 is inserted into According to the oil tank pole socket 44 fixed on the casing 43, the lower end of the control meter box pole 15 is plugged into the control instrument box pole socket 42 fixed on the casing 43, and the float chamber cover plate 20 is fixed by the screw 39. Fastened on the casing 43 above the float chamber 11, the oil drain valve 12 at the bottom of the float chamber 11 protrudes from the outside of the casing 43, and the lower part of the float chamber 11 communicates with the bottom of each oil tank 10 through a connecting oil pipe 37. The upper part of the oil tank 10 and the middle part of the float chamber 11 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com