Wire and cable transport and pay-off vehicle

A technology for wire and cable and pay-off car, which is applied to cable laying equipment and other directions, can solve the problems of increasing the use cost of cranes, high cost, inconvenient operation, etc., and achieve the effect of improving work efficiency of pay-off, wide application range and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

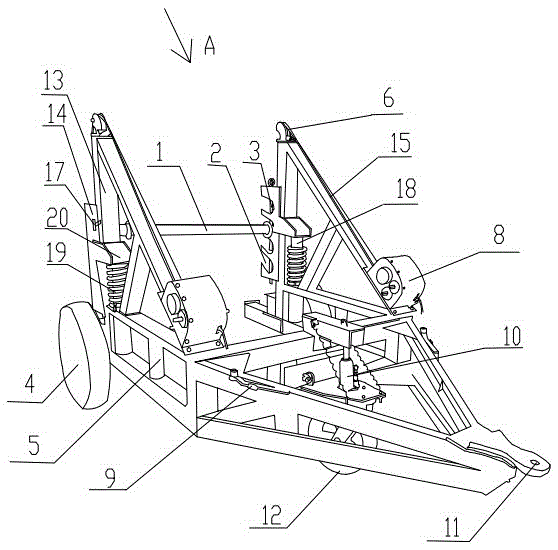

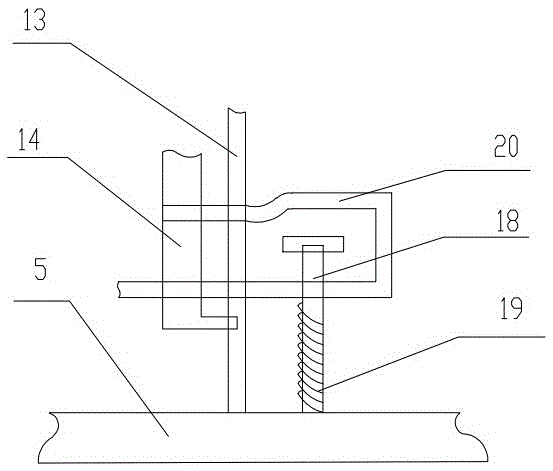

[0021] see Figure 1 ~ Figure 3 , the invention discloses a wire and cable transport and pay-off vehicle, which includes wheels 4, a vehicle frame 5 and tractor connecting buckles 11 arranged at the front of the vehicle frame 5, and the columns 13 on both sides of the vehicle frame 5 are respectively provided with symmetrical The threading shaft lifting mechanism, the threading shaft lifting mechanism includes a lifting frame 14 with more than one open slot 2, the lifting frame 14 and the column 13 are slidingly matched, and the lifting frame 14 is connected to the fixed pulley 6 on the upper end of the steel wire rope 15 and the column 13. The rope rollers on both sides of the vehicle frame 5 are connected to the lifting self-locking drive mechanism; the threading shaft 1 is placed in the corresponding open slots 2 on both sides, and a threading shaft anti-slip mechanism is provided.

[0022] The lifting self-locking driving mechanism is a hand-operated worm gear reducer 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com