Novel dyeing control system and control method thereof

A technology of control system and control method, which is applied in the field of dyeing machines, can solve the problems of invoking process and control, costing money, and being unusable, and achieves the effects of simple control, simple use, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

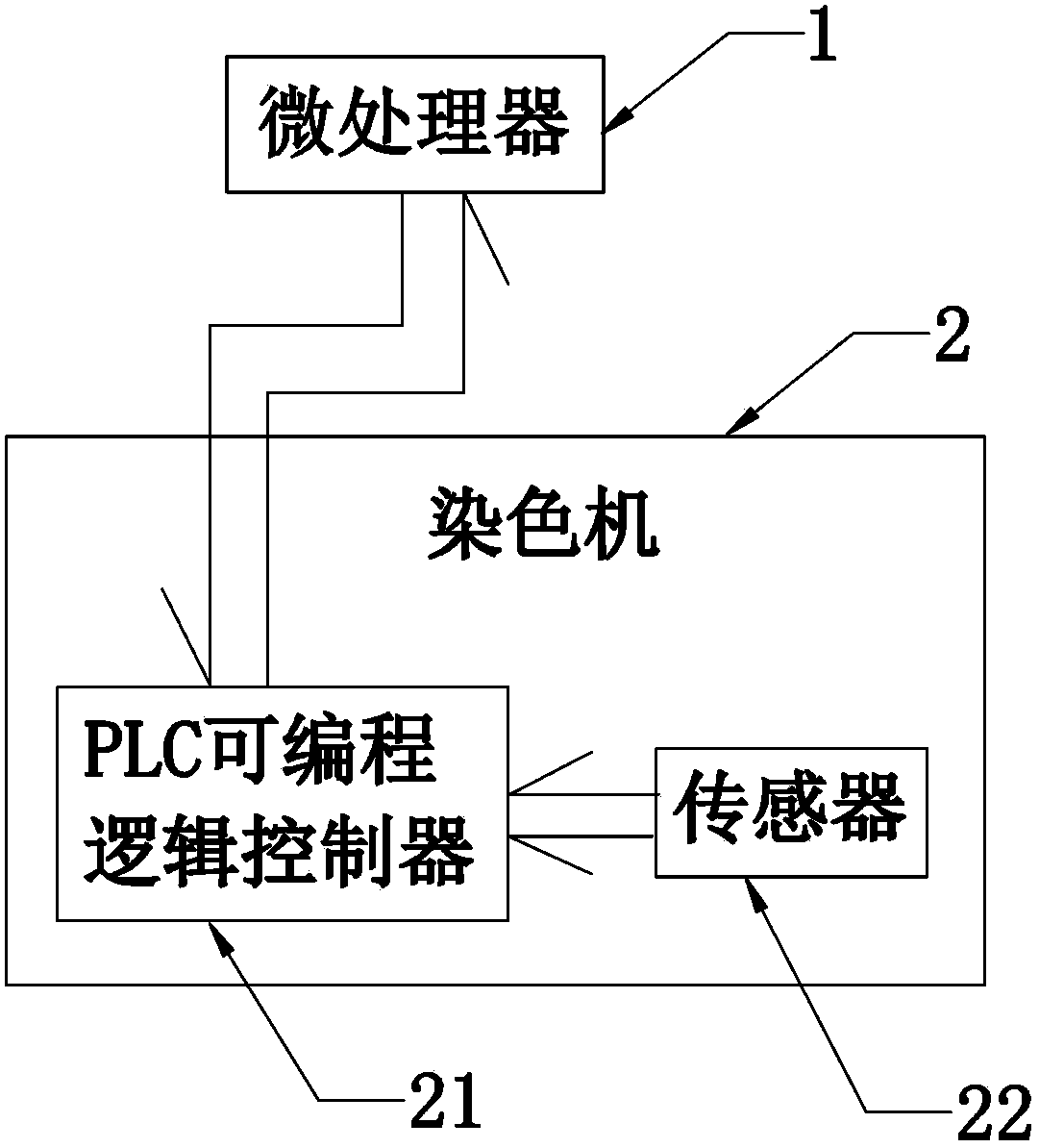

[0026] Such as figure 1 As shown, the new dyeing control system of the present invention includes a microprocessor 1 and a dyeing machine 2 that have high compatibility and can modify internal software as required; the microprocessor 1 is electrically connected to the dyeing machine 2, and the The motherboard structure of the microprocessor is based on one of the X86 motherboard structure or the ARM motherboard structure, and the dyeing machine 2 includes a PLC programmable logic controller 21 and a sensor 22, and the PLC programmable logic controller 21 and the sensor 22 Electrically connected. The microprocessor 1 sends the control information to the PLC programmable logic controller 21 to realize the exchange of information data, thereby controlling the dyeing machine 2 to make corresponding operations; Work information is fed back to the PLC programmable logic controller 21, and the PCL programmable logic controller 21 then transmits the feedback information to the microp...

Embodiment 2

[0036] This embodiment is exactly the same as the novel dyeing control system described in Embodiment 1, the only difference is that the steps of modifying the process are added to the control method of the novel dyeing control system, as follows:

[0037] (1) Establishment process;

[0038] Create a new production process and store it in the microprocessor. First enter the process number, which is customized according to each manufacturer. Then click the "increase" button, and the editing interface will be displayed in the microprocessor 1, and the operator can edit the specific content of the production flow process in the editing box in the editing interface, and finally click the "confirm" button, and the microprocessor will Processor 1 saves the edited content in a folder with the process number as the folder name according to the process number.

[0039](2) Modify the process;

[0040] Modify the corresponding production flow process according to the problems in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com