A Realization Method of Custom Test Function Sequence in Microwave Measuring Instrument

A technology for testing functions and implementation methods, applied in the fields of instruments, measuring electricity, measuring devices, etc., can solve the problems that are not conducive to the development of the application layer of the instrument, the system software is inconvenient to share, and the use is inconvenient, so as to improve the test efficiency and standardize the test. Process and test parameters, the effect of convenient development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The realization of the invention includes two parts: custom test function sequence editing function, custom test function sequence internal function realization,

[0026] 1. Realization of custom test function sequence editing function

[0027] In the command file selection dialog box of a custom menu key setting, select or input the command file corresponding to the custom key, and replace the string of "custom menu key 1" with the file name of the command file minus the extension. In this way, the custom test function sequence is given to the custom menu 1, and the custom test function can be executed by clicking this menu.

[0028] 2. Internal function implementation of custom test function sequence

[0029] The internal protocol format, storage format and keyword design of the command file:

[0030] Use the SCPI program-controlled instructions in the test instrument to create a command file. The syntax format follows the standard SCPI (Standard Command Set for Pro...

Embodiment 2

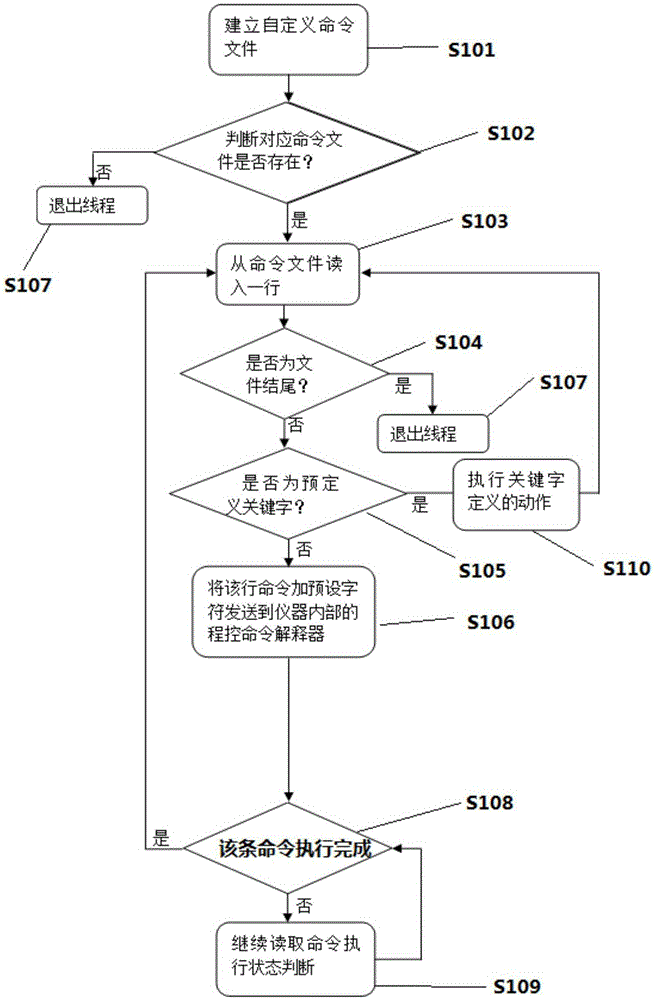

[0063] On the basis of the above embodiments, further, a method for realizing a self-defined test function sequence in a microwave measuring instrument is provided, which includes the following steps:

[0064] Step S101: Create a custom file;

[0065] Step S102: judge whether the corresponding command file exists, if yes, go to step S103; otherwise, go to step S107;

[0066] Step S103: read one line from the command file;

[0067] Step S104: judge whether it is the end of the file, if yes, go to step S107; otherwise, go to step S105;

[0068] Step S105: judge whether it is a predefined keyword, if it is then enter step S110; if otherwise enter step S106;

[0069] Step S106: After sending the line command plus preset characters to the program-controlled command interpreter inside the instrument, enter step S108;

[0070] Step S107: Exit the thread;

[0071] Step S108: judge whether step S106 is completed, if yes, go to step S103; otherwise, go to step S109;

[0072] Step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com