Mild steel and friction damper

A friction damper and mild steel technology, which is applied to building components and anti-vibration, can solve the problems of device failure, large error in calculated parameters, and reduced energy consumption effect, and achieves a simple structure, uniform force, and material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

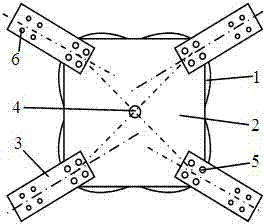

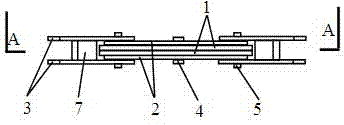

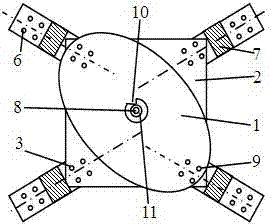

[0016] Mild steel and friction damper proposed by the present invention such as Figure 1~Figure 3 shown. The whole device is mainly composed of oval friction plate 1, mild steel plate 2, fixed plate 3, central axis anchor bolt 4, energy dissipation plate body installation anchor bolt 5, mounting screw hole 6, backing plate 7, central axis screw hole 8, fixed plate Screw hole 9, friction plate spring bayonet 10 and spring 11 etc. are formed.

[0017] According to actual requirements, respectively excavate the fixing plate screw holes 9 for the oval friction plate 1 and the soft steel plate 2; drill holes for the centroid of the oval friction plate 1, and form the friction plate spring bayonet 10, two friction plate springs The bayonet opening direction of the bayonet socket 10 is opposite. Set the spring 11 between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com