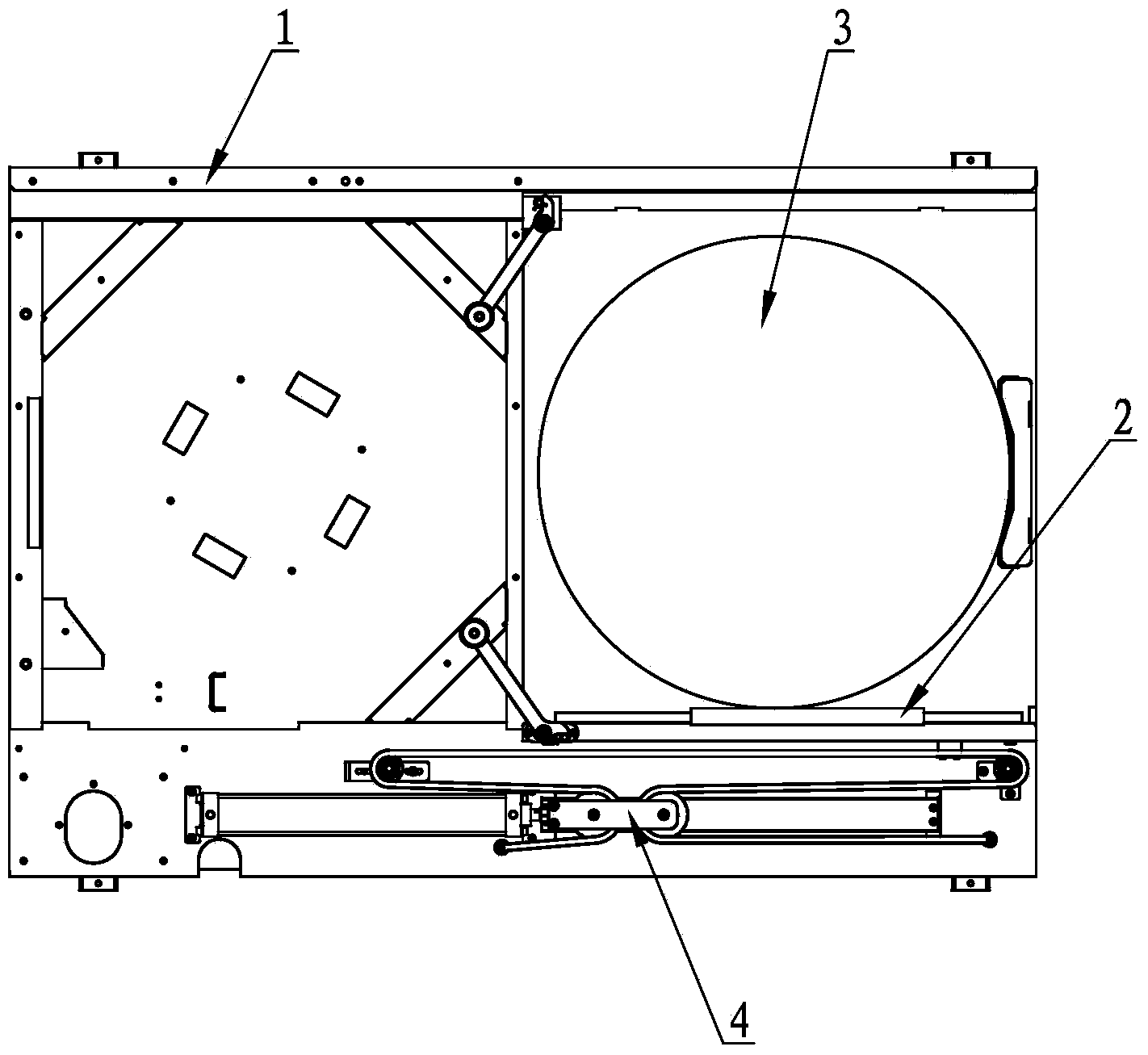

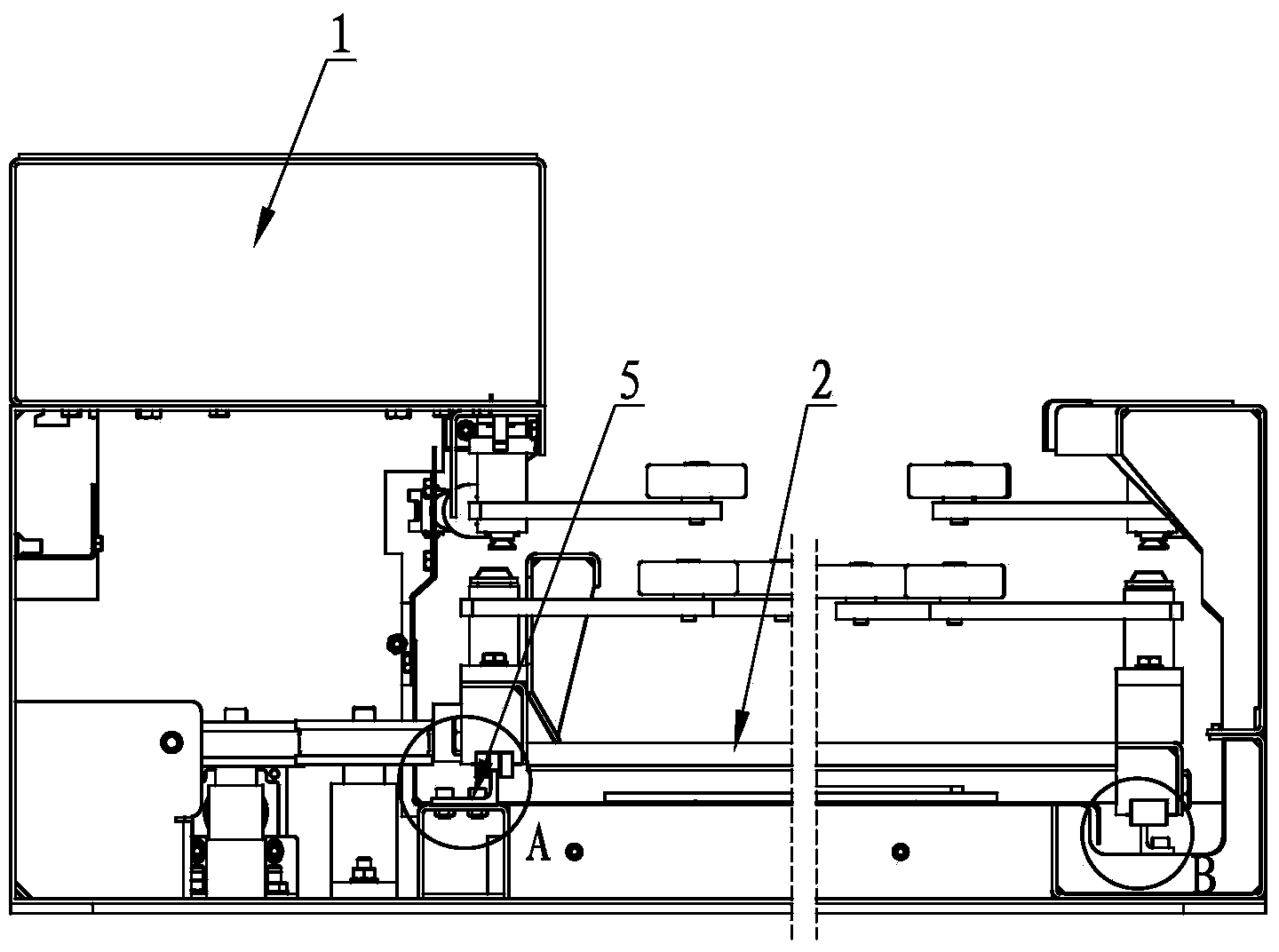

Creeling transmission mechanism for coiler of carding machine

A technology of a transmission mechanism and a coiler, which is applied to deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of high cost of nylon steel core belt 44, aggravated belt 44 wear, belt 44 breakage, etc., and achieves the transmission structure. Stable and reliable, fast and economical maintenance, low probability of chain breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

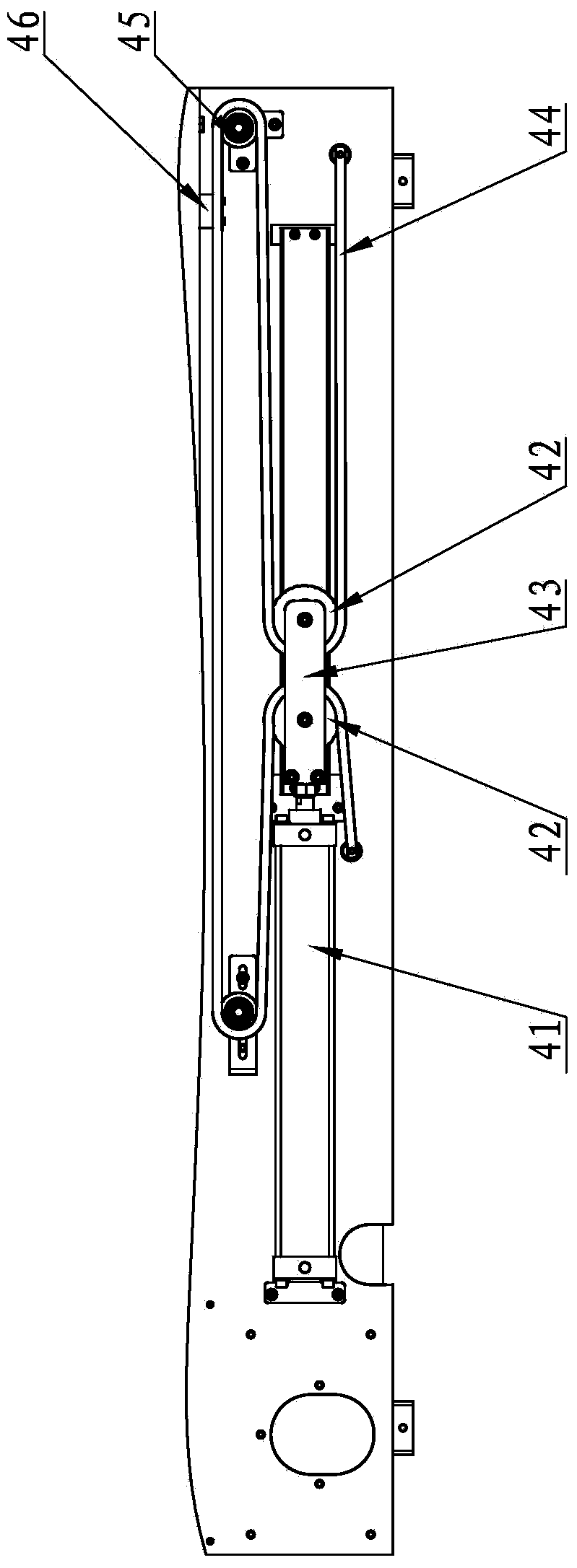

[0020] Embodiment 1: a kind of cylinder changing transmission mechanism of carding machine coiler, such as Figure 5 , Figure 6 Shown, comprise drive cylinder 41, two movable sprockets 47, linkage frame 43, chain 48, two fixed sprockets 49 and trolley drive connection block 46, the cylinder body of drive cylinder 41 is fixed on fuselage 1 bottom plate, two A moving sprocket 47 is installed on the linkage frame 43, and the linkage frame 43 is fixedly installed on the piston rod of the drive cylinder 41, and one end of the chain 48 is fixedly installed on the bottom plate of the fuselage 1, and then bypasses the two moving sprockets 47 and the two in turn. A fixed sprocket 49, the other end is also fixedly installed on the base plate of the fuselage 1, and the trolley drive connection block 46 is fixedly connected with the chain 48, and when the piston rod of the drive cylinder 41 is stretched, it will synchronously drive the two moving parts fixed on the linkage frame 43 The ...

Embodiment 2

[0021] Embodiment 2: In Embodiment 1, the fixed sprocket 49 on the left is designed as an adjustable structure along the reciprocating linear movement direction of the chain, so that the tension adjustment of the chain 48 can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com